Preparation method of dibasic acid amine salt, dibasic acid amine salt solution, dibasic acid amine salt and polymer

A technology of dibasic acid amine salt and dibasic acid salt, which is applied in the field of high-quality dibasic acid amine salt, and can solve problems such as complexity, high cost of polymerization products, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

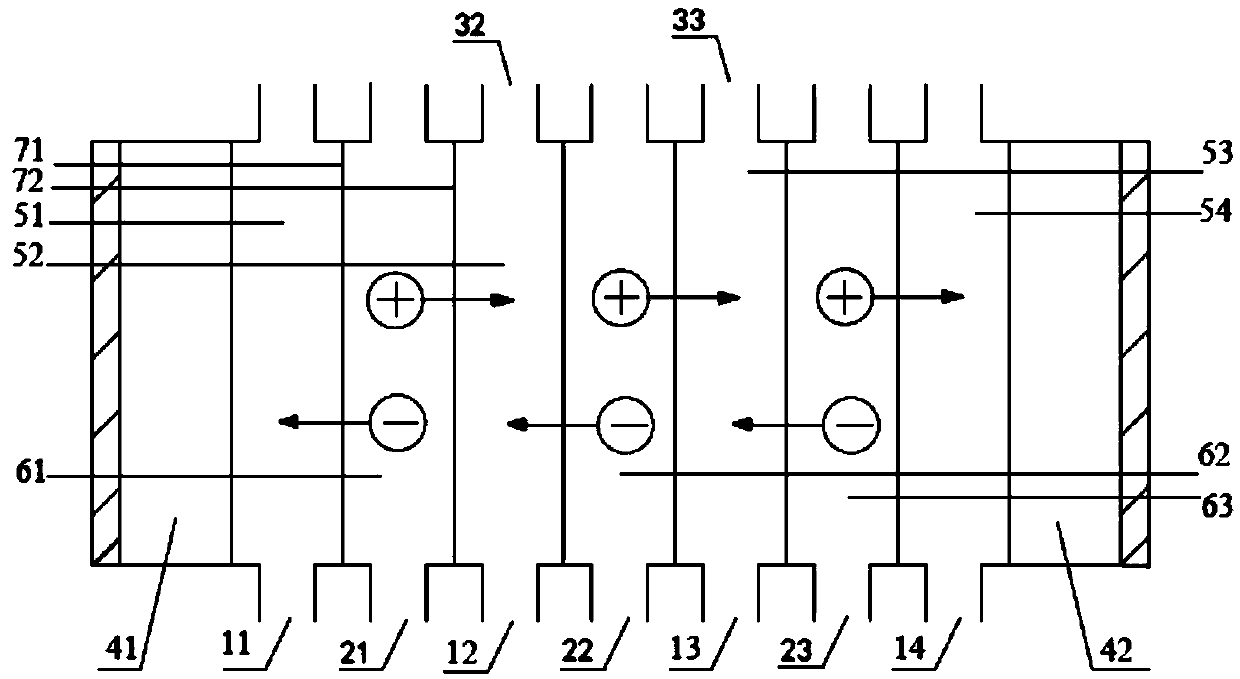

[0081] The electrodialysis device includes: negative membranes 71 and positive membranes 72, and the negative membranes 71 and positive membranes 72 are arranged alternately to form concentrating chambers and desalination chambers, and the concentrating chambers and desalination chambers are arranged alternately. In this embodiment, there is no limitation on the number of positive and negative membranes.

[0082] Meanwhile, the concentration chambers 51 , 52 , 53 , 54 are connected to the feed ports 11 , 12 , 13 , 14 respectively, and the desalination chambers 61 , 62 , 63 are connected to the feed ports 21 , 22 , 23 respectively. The concentrating pipes 32 and 33 for discharging the concentrated liquid communicate with the concentrating chambers 52 and 53 respectively. Those skilled in the art understand that the electrodialysis device also includes two electrode chambers 41 and 42 on both sides.

[0083] Feed inlets 11, 12, 13, 14 feed water, feed inlets 21, 22, 23 respecti...

Embodiment 2

[0085] Preparation of pentamethylenediamine adipate

[0086] (1) Get 1,5-pentamethylenediamine sulfatase conversion solution for subsequent use (wherein the concentration of 1,5-pentamethylenediamine ion is 7wt%, pH value is 6.5, 1,5-pentamethylenediamine sulfatase conversion solution Color: dark brown, purchased from Kaisai (Jinxiang) Biomaterials Co., Ltd.).

[0087] React with adipic acid and ammonia in water to configure ammonium adipate solution (the mass concentration of ammonium adipate in the ammonium adipate solution is 10wt%, and the pH value is 6.8.)

[0088] (2) Ammonium adipate solution and 1,5-pentamethylenediamine sulfatase conversion solution are passed through the desalination chamber of the electrodialysis device as implementing 1, wherein, 1,5-pentamethylenediamine sulfatase conversion solution is passed into The desalination chamber 62 and the desalination chamber 61,63 that pass into the ammonium adipate solution are arranged at intervals. 5wt% sodium su...

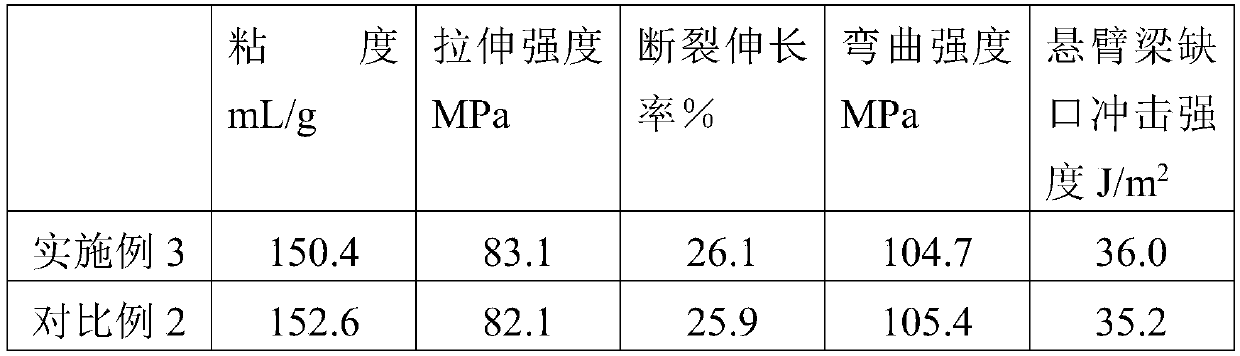

Embodiment 3

[0092] Preparation of pentamethylenediamine sebacate

[0093] (1) Take 1,5-pentamethylenediamine sulfatase conversion solution (wherein the concentration of 1,5-pentamethylenediamine ion is 4wt%, pH value is 6.5, color: dark brown, purchased from Kaisai (Jinxiang) Biomaterials Limited);

[0094] Use sebacic acid and ammonia to react in water to prepare an ammonium sebacate solution (the concentration of ammonium sebacate in the ammonium sebacate solution is 7.9 wt%, and the pH value is 7.0).

[0095] (2) ammonium sebacate solution and 1,5-pentamethylenediamine sulfatase conversion solution are passed through the desalination chamber of the electrodialysis device as implementing 1, wherein, feed 1,5-pentamethylenediamine sulfatase conversion solution The desalination chamber 62 and the desalination chamber 61,63 that pass into the ammonium sebacate solution are arranged at intervals. 5wt% sodium sulfate aqueous solution is passed into the pole chamber 41 and the pole chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Ion exchange capacity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com