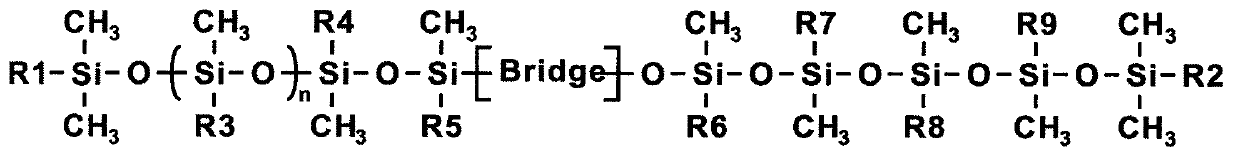

Preparation method and application of polyacrylic acid grease bridging polysilsesquioxane precursor zwitterionic emulsion system

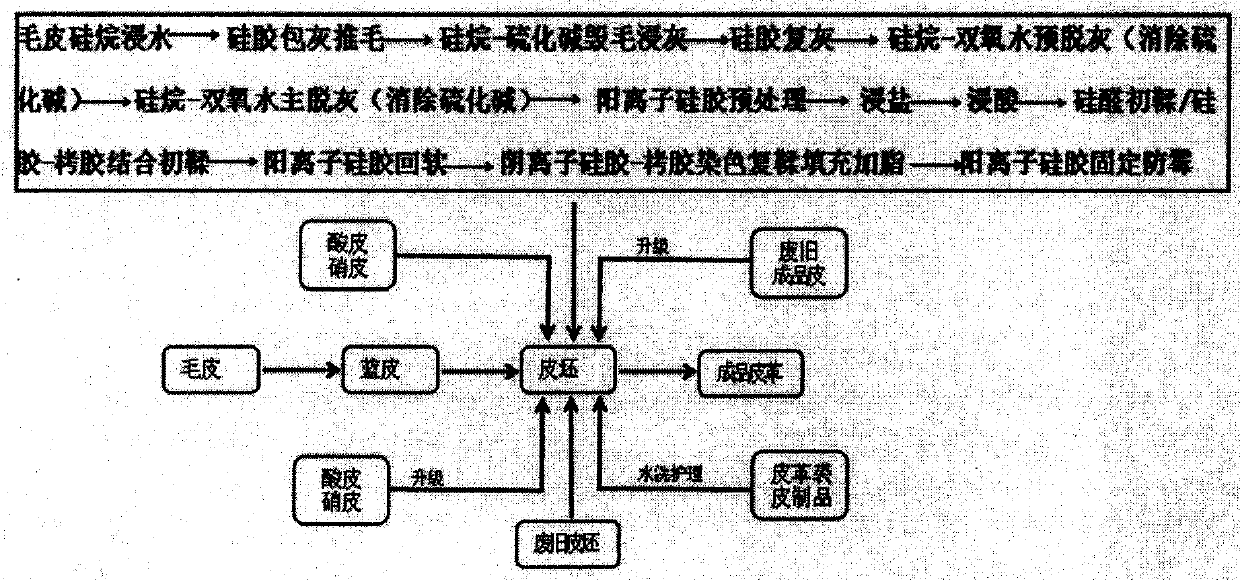

A technology of silsesquioxane and polyacrylic acid, applied in application, tanning treatment, animal husbandry, etc., can solve problems such as unreported, and achieve the effect of good water solubility and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

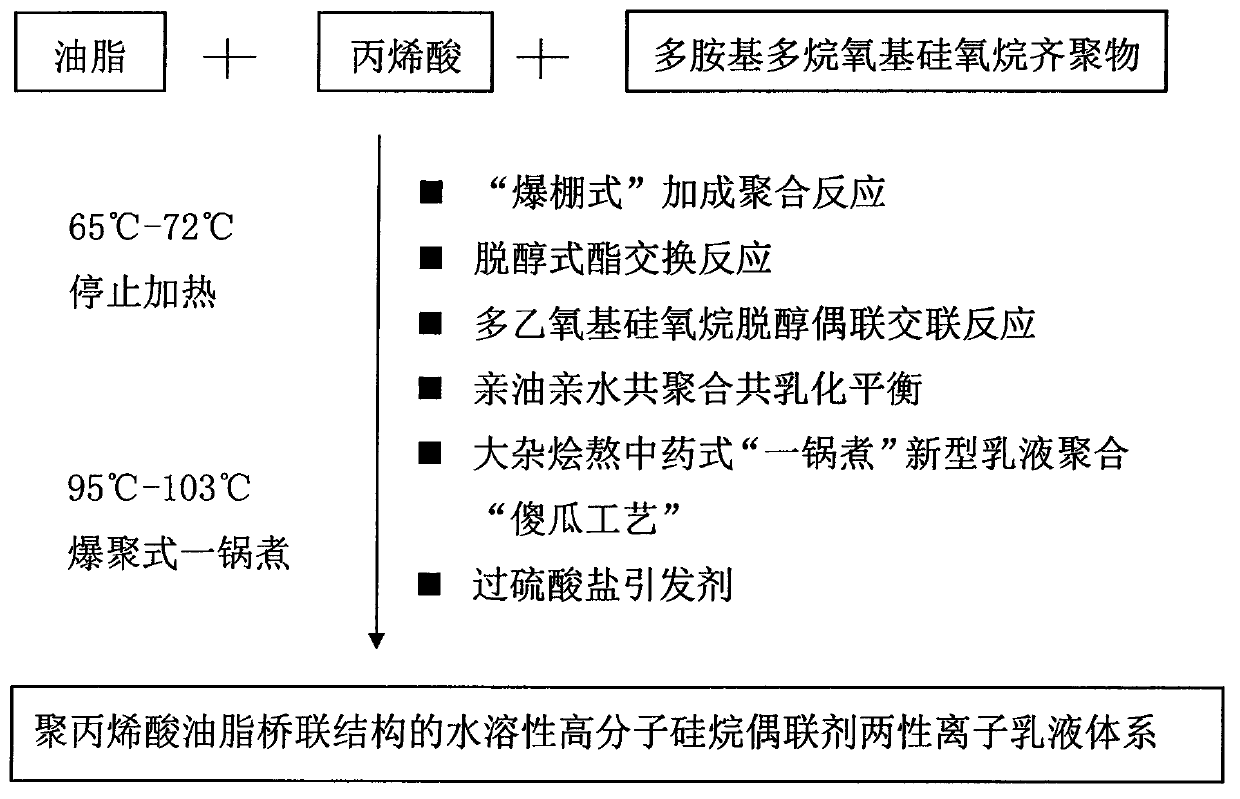

Method used

Image

Examples

Embodiment 1

[0038] The water-soluble polymer silane coupling agent zwitterionic emulsion system of the polyacrylic acid oil bridging structure is characterized in that: it comprises the following components, by mass percentage:

[0039] Precursor 1: 8.61%, Precursor 2: 2.11%, Precursor 3: 0.70%, Industrial Lecithin: 13.70%, Industrial Acrylic Acid: 5.71%, Potassium Persulfate: 0.04%, Thinner: 50.91%, Industrial Caustic Soda Aqueous solution: 1.67%, foaming agent: 15.54%, industrial fungicide: 0.57%, precursor 4: 0.44%;

[0040] Its preparation method comprises the following steps:

[0041] (1) Add the mass percentage of precursor 1, precursor 2, precursor 3, and industrial lecithin to the reaction kettle in sequence, start stirring, stir for 10 minutes, then add industrial acrylic acid, stir while adding, stir for 5 minutes, get the primary reactants;

[0042] (2) Add potassium persulfate initiator, stir for 5 minutes, heat up to 50°C, observe, continue to heat up to 58°C, stop heating,...

Embodiment 2

[0046] A water-soluble high molecular weight silane coupling agent zwitterionic emulsion system of a polyacrylic acid oil bridging structure, characterized in that: it comprises the following components, in percent by mass:

[0047] Precursor 1: 8.61%, Precursor 2: 2.11%, Precursor 3: 0.70%, Industrial rapeseed oil: 13.70%, Industrial acrylic acid: 5.71%, Potassium persulfate: 0.04%, Thinner: 50.91%, Industrial flakes Alkaline aqueous solution: 1.67%, foaming agent: 15.54%, industrial fungicide: 0.57%, precursor 4: 0.44%;

[0048] Its preparation method comprises the following steps:

[0049] (1) Add the mass percentage of precursor 1, precursor 2, precursor 3, and industrial rapeseed oil to the reaction kettle in sequence, start stirring, and stir for 10 minutes, then add industrial acrylic acid, stir while adding, and stir for 5 minutes , get the primary reactant;

[0050] (2) Add potassium persulfate initiator, stir for 5 minutes, heat up to 50°C, observe, continue to hea...

Embodiment 3

[0054] A water-soluble high molecular weight silane coupling agent zwitterionic emulsion system of a polyacrylic acid oil bridging structure, characterized in that: it comprises the following components, in percent by mass:

[0055] Precursor 1: 8.61%, Precursor 2: 2.11%, Precursor 3: 0.70%, Industrial lanolin: 13.70%, Industrial acrylic acid: 5.71%, Potassium persulfate: 0.04%, Thinner: 50.91%, Industrial caustic soda Aqueous solution: 1.67%, foaming agent: 15.54%, industrial fungicide: 0.57%, precursor 4: 0.44%;

[0056] Its preparation method comprises the following steps:

[0057] (1) Add the mass percentage of precursor 1, precursor 2, precursor 3, and industrial lanolin to the reaction kettle in sequence, start stirring, and stir for 10 minutes, then add industrial acrylic acid, stir while adding, and stir for 5 minutes, get the primary reactants;

[0058] (2) Add potassium persulfate initiator, stir for 5 minutes, heat up to 50°C, observe, continue to heat up to 72°C, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com