A kind of preparation method of powder phospholipid

A technology for powdered phospholipids and phospholipids, which is applied in the fields of fat oil/fat refining, chemical instruments and methods, and fat production, can solve the problems of lack of industrialization feasibility, reduced production costs, long drying time, etc., and is beneficial to food safety and shelf life. Shorter, longer drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

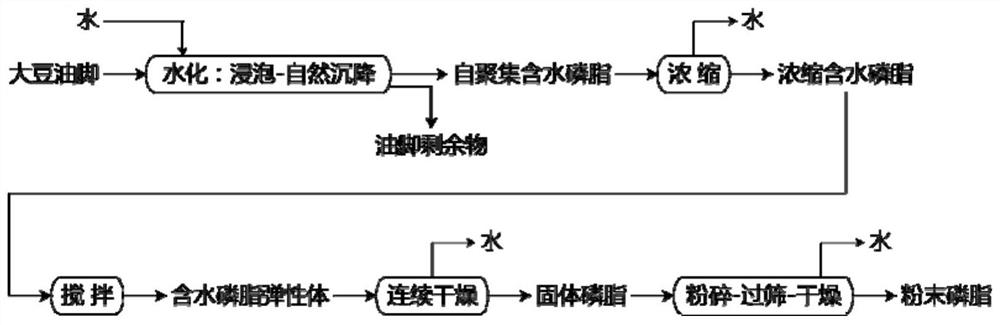

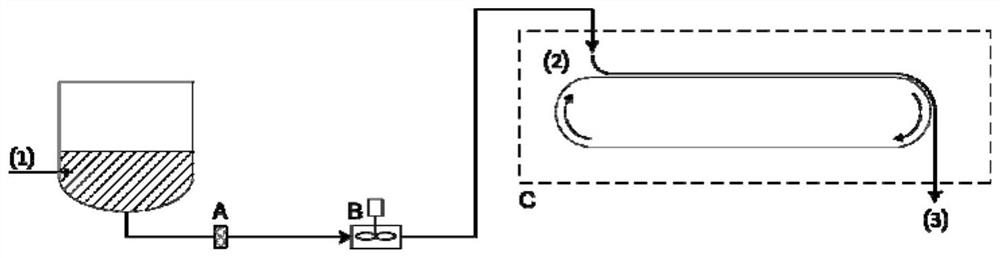

[0057] A kind of preparation method of powder phospholipid, with reference to attached figure 1 And attached figure 2 , including the following steps:

[0058] (1) Hydration: Add soybean oil feet into water, break up the oil feet in the water into granules by stirring, and form an immersion system with soybean oil feet particles as the dispersed phase and water as the continuous phase. The soaking temperature is 60°C , soaking time is 3h, get saturated water-absorbing oil feet. The saturated water-absorbing oil foot is marked by the appearance of brown self-aggregated water-containing phospholipids.

[0059] The soybean oil foot comes from COFCO Jiayue (Tianjin) Co., Ltd., and its material composition: the water content is 41.03g / 100g, the dry base acetone insoluble matter content is 61.13g / 100g; the water is drinking water; the oil foot The mass ratio to water is 1:1; the particle diameter of the oil foot particles is 0.3-3mm.

[0060] Saturate the water-absorbing oily f...

Embodiment 2

[0067] A kind of preparation method of powder phospholipid, with reference to attached figure 1 And attached figure 2 , including the following steps:

[0068] (1) Hydration: Add soybean oil feet into water, break up the oil feet in the water into granules by stirring, and form an immersion system with soybean oil feet particles as the dispersed phase and water as the continuous phase. The soaking temperature is 70°C , soaking time is 3h, get saturated water-absorbing oil feet. The saturated water-absorbing oil foot is marked by the appearance of brown self-aggregated water-containing phospholipids.

[0069] The oil foot comes from COFCO Cereals and Oils Industry (Jiujiang) Co., Ltd., and its material composition: the water content is 37.56g / 100g, and the dry base acetone insoluble matter content is 60.87g / 100g; the water is drinking purified water, added to the water The sodium chloride of table salt is added in an amount of 0.07% of the weight of drinking purified water;...

Embodiment 3

[0077] A kind of preparation method of powder phospholipid, with reference to attached figure 1 And attached figure 2 , including the following steps:

[0078] (1) Hydration: Add soybean oil feet into water, break up the oil feet in the water into granules by stirring, and form an immersion system with soybean oil feet particles as the dispersed phase and water as the continuous phase. The soaking temperature is 80°C , soaking time is 2h, get saturated water-absorbing oil feet. The saturated water-absorbing oil foot is marked by the appearance of brown self-aggregated water-containing phospholipids.

[0079] The oil foot comes from COFCO Cereals and Oils Industry (Huanggang) Co., Ltd., and its material composition: the water content is 38.42g / 100g, and the dry base acetone insoluble matter content is 61.02g / 100g; The food additive lactic acid with a concentration of 80% is added in an amount of 0.05% of the weight of purified drinking water; the mass ratio of oily feet to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com