Gypsum plaster board with antibacterial, mildew-proof and formaldehyde-removing functions and preparation method thereof

A paper surface gypsum board and aldehyde-cleaning technology, which is applied in the field of building materials, can solve the problems of environmental pollution, industrial by-product gypsum occupying land resources, etc., achieve strong antibacterial performance, improve the adhesive performance of paper surface, and expand the antibacterial range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

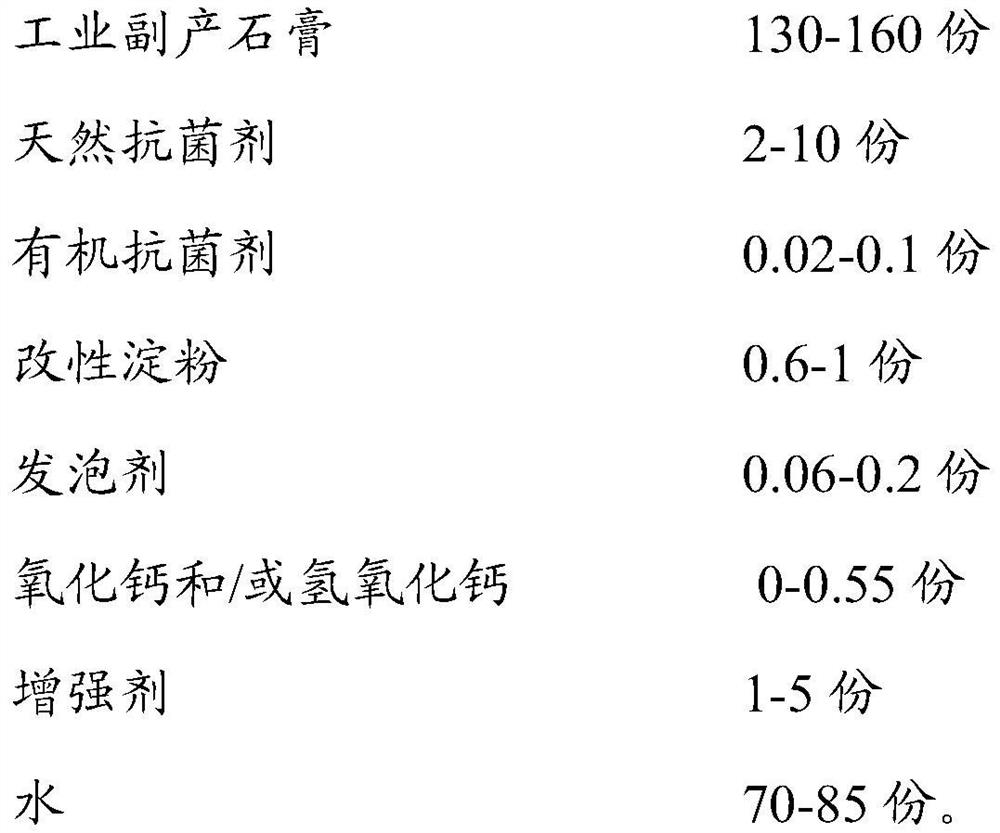

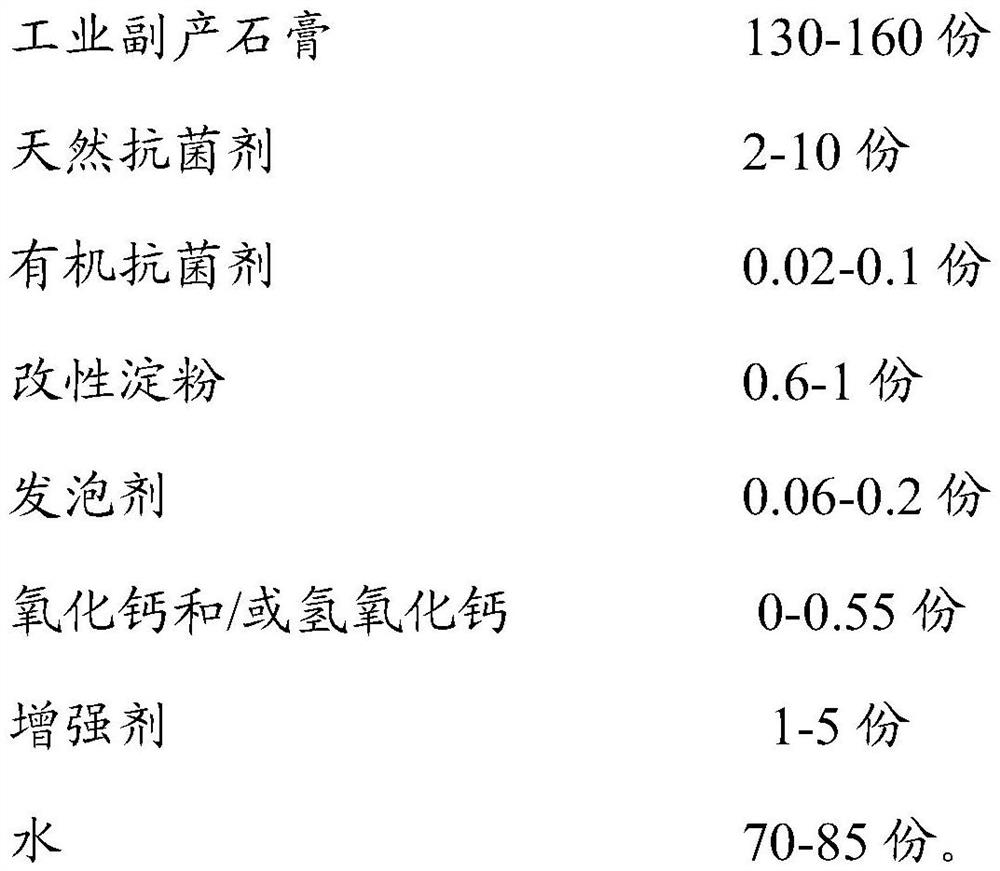

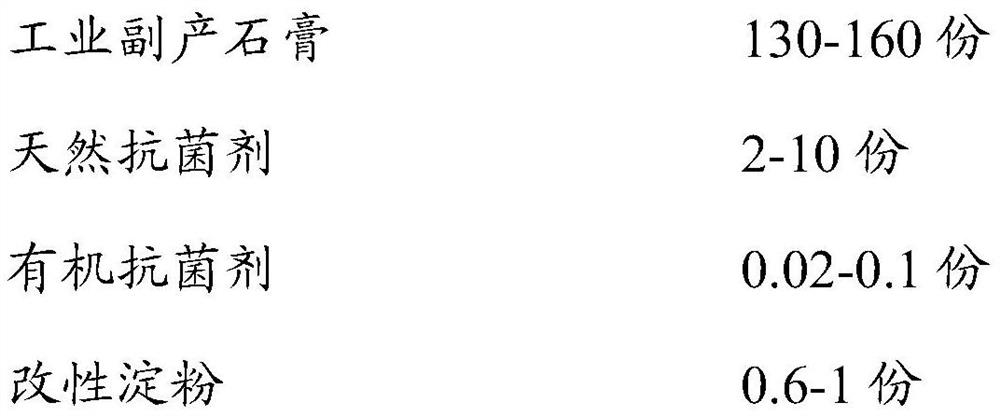

[0035] The raw materials of the paper surface gypsum board of the present embodiment are: 130 parts by weight of phosphogypsum, 5 parts by weight of chitosan, 0.05 parts by weight of tetrakis hydroxymethyl phosphorus sulfate, 0.8 parts by weight of modified corn starch, and 0.1 parts by weight of sodium lauryl sulfate. parts by weight, 0.2 parts by weight of CaO, 3 parts by weight of glass fiber and 75 parts by weight of water.

[0036] The gypsum board of the present embodiment is prepared by the following method:

[0037] Step 1: Pour chitosan and tetrakis hydroxymethyl phosphorus sulfate into water, and mechanically stir evenly to obtain a mixed antibacterial liquid;

[0038] Step 2: adding modified cornstarch, sodium lauryl sulfate, and glass fiber to the mixed antibacterial solution obtained in step 1, and mechanically stirring to obtain a mixed solution;

[0039] Step 3: Calcining phosphogypsum at 180°C to make building gypsum powder (about 100 parts by weight), mixing ...

Embodiment 2

[0044] The raw materials of the paper surface gypsum board of the present embodiment are: 130 parts by weight of phosphogypsum, 10 parts by weight of chitosan, 0.1 part by weight of tetrakis hydroxymethyl phosphorus sulfate, 1.0 part by weight of modified corn starch, 0.2 parts by weight of sodium lauryl sulfate parts by weight, 0.4 parts by weight of CaO, 5 parts by weight of glass fiber and 85 parts by weight of water.

[0045] The preparation method of the paper-faced gypsum board is the same as in Example 1, wherein the pH value of the mixed powder of phosphogypsum and CaO obtained in Step 3 is 6.5.

Embodiment 3

[0047] The raw materials of the paper surface gypsum board of the present embodiment are: 150 parts by weight of fluorogypsum, 3 parts by weight of chitosan, 0.03 parts by weight of polyhexamethylene biguanide hydrochloride (PHMB), 0.7 parts by weight of modified soybean starch, fat Alcohol polyoxyethylene ether sodium sulfate 0.08 parts by weight, Ca(OH) 2 0.13 parts by weight, 2 parts by weight of basalt fiber and 75 parts by weight of water.

[0048] The gypsum board of the present embodiment is prepared by the following method:

[0049] Step 1: Pour chitosan and polyhexamethylene biguanide hydrochloride (PHMB) into water, and mechanically stir evenly to obtain a mixed antibacterial liquid;

[0050]Step 2: adding modified soybean starch, fatty alcohol polyoxyethylene ether sodium sulfate, and basalt fiber to the mixed antibacterial solution obtained in step 1, and mechanically stirring to obtain a mixed solution;

[0051] Step 3: Calcining fluorogypsum at 180°C to make b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com