Separation and purification process and device for bacca sedge polysaccharide

A technology for separation and purification of red barnyard, applied in the field of raw material extraction, can solve the problems of high loss rate of red barnyard polysaccharide, low extraction rate, etc., and achieve the effects of good separation and purification effect, increase extraction rate, and avoid raw material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

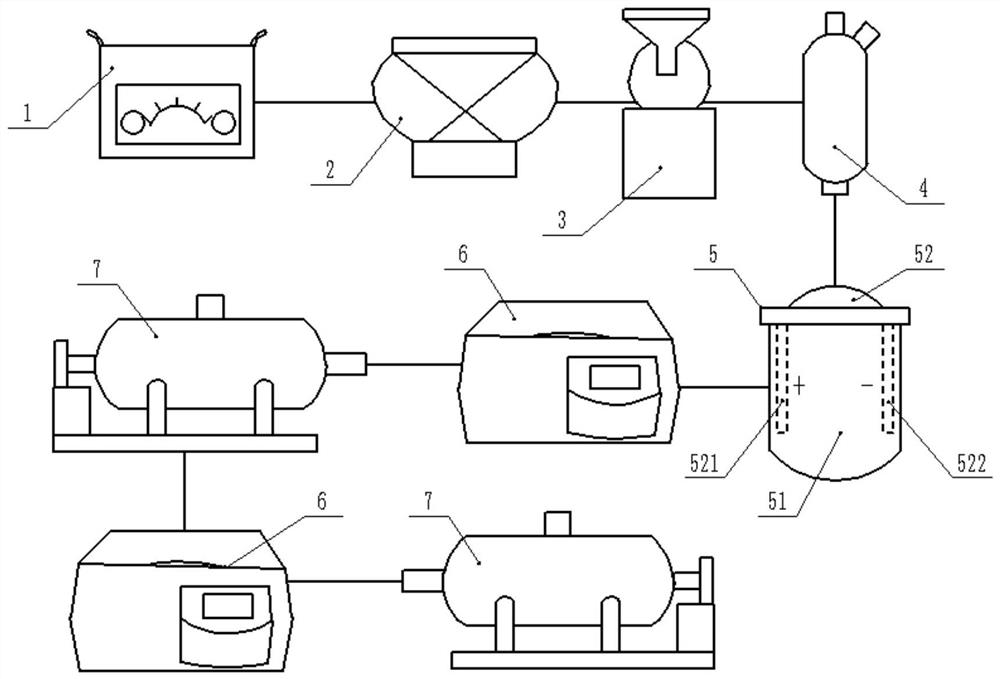

[0037] Embodiment 1: a kind of separation and purification process of red barnyard barnyard polysaccharide mainly comprises the following steps:

[0038] S1: Preprocessing

[0039] Take red barnyard fruit and place it in 0.1mol / L dilute hydrochloric acid solution, ultrasonically soak it in ultrasonic cleaning machine 1 for 2 hours, rinse the red barnyard fruit after soaking with deionized water twice to remove the sticky impurities of red barnyard fruit, and then Dry at 60°C for 4-5 hours to break the shell of the red barnyard fruit, then use the gravity sorter 2 to remove the shell of the red barnyard fruit, send the shell-removed red barnyard fruit to the grinder 3 for crushing, and after crushing The red barnyard fruit is passed through a 100-mesh sieve, dried at 80°C for 2 hours, and red barnyard powder is obtained after degreasing;

[0040] The specific process of degreasing is: dissolving red barnyard powder and deionized water in the extraction tank 4 according to the ma...

Embodiment 2

[0048] It is basically the same as Embodiment 1, except that in S2, the positive and negative poles of the high-voltage pulse extraction device 5 are alternated before each high-voltage pulse extraction,

[0049] Add the β-glucan clathrate solution to the first extraction solution, repeat the above high-pressure pulse extraction step, and the extraction time is 5 minutes, to obtain the second extraction solution;

[0050] Add the β-glucan clathrate solution to the second extraction solution, repeat the above-mentioned high-pressure pulse extraction step, and the extraction time is 10 minutes, to obtain the third extraction solution;

[0051] Add the β-glucan inclusion compound solution to the third extraction solution, repeat the above-mentioned high-pressure pulse extraction step, and the extraction time is 40 minutes to obtain the fourth extraction solution. The volume ratio of the β-glucan inclusion compound solution added three times is is 1:3:7,

[0052] The preparation ...

experiment example 1

[0058] Experimental Example 1: Studying the Effect of β-Glucan Inclusion Complex on the Extraction Efficiency of Red Barnyard Polysaccharide

[0059] Using the process provided in Example 1 and Example 2 to separate and extract the same amount of red barnyard polysaccharides, respectively prepare red barnyard polysaccharide A and red barnyard polysaccharide B, and measure the red barnyard polysaccharides of embodiment 1 and embodiment 2 by the following formula Extraction rate:

[0060] Red barnyard polysaccharide extraction rate = red barnyard polysaccharide mass / red barnyard fruit mass * 100%,

[0061] Calculate respectively the red barnyard barnyard polysaccharide extraction rate of embodiment 1, embodiment 2, and the results are as shown in table 1:

[0062] The red barnyard barnyard polysaccharide extraction rate test result table of table 1 embodiment 1, embodiment 2

[0063] group Red barnyard fruit mass / g Red barnyard polysaccharide mass / g Extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com