Adhesive based on photo-induced solid-liquid conversion of azobenzene compound

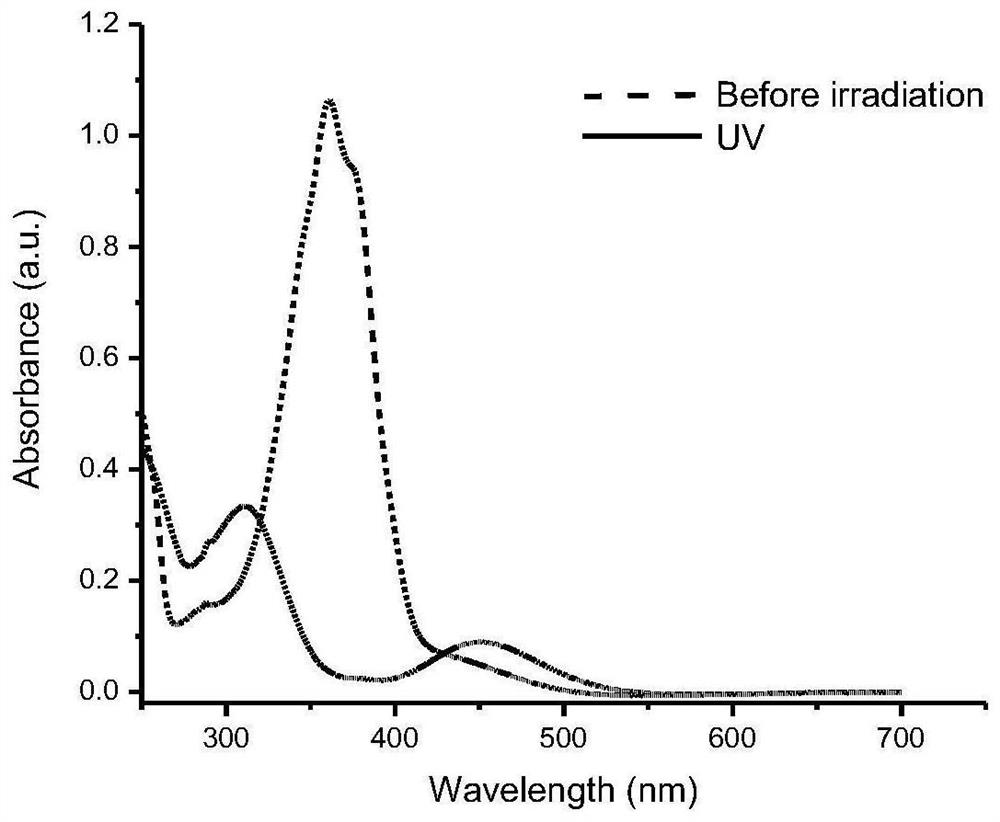

A solid-liquid conversion, methyl azobenzene technology, used in non-polymer organic compound adhesives, adhesive types, polyurea/polyurethane adhesives, etc. Transportation difficulties and other problems, to achieve the effect of improving bonding strength, convenient transportation, and convenient liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

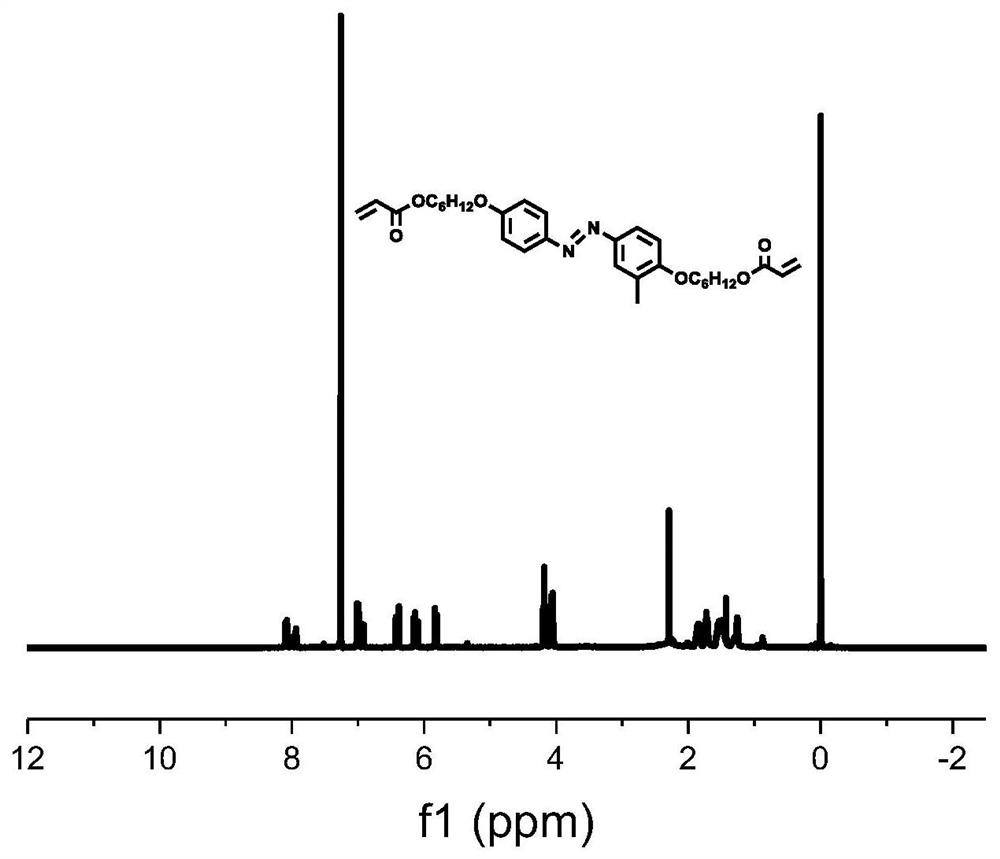

[0076] Preparation of 4,4'-hexyl diacrylate-3-methylazobenzene derivatives

[0077] 1) Preparation of 4,4'-dihydroxy-3-methylazobenzene: under stirring conditions, add sodium nitrite aqueous solution dropwise to p-aminophenol acidic aqueous solution with pH=1~2, and control the reaction temperature to 0 ℃, continue to react for 0.5 hours after the dropwise addition, and obtain the diazonium salt solution of p-aminophenol, wherein the molar ratio of p-aminophenol to sodium nitrite is 1:1.1; Add the above-mentioned diazonium salt solution of p-aminophenol dropwise to an alkaline aqueous solution of 10 o-cresol, react at room temperature for 4 hours after the dropwise addition, add hydrochloric acid to precipitate the product, wherein the molar ratio of p-aminophenol to o-cresol is 1 :1. The water was extracted and dried, separated and purified by column chromatography with ethyl acetate:petroleum ether=1:4 eluent, the solvent was removed and then dried to obtain 4,4'-dihydroxy-...

Embodiment 2

[0085] Completely dissolve 48.25 g of 4,4'-hexyl diacrylate-3-methylazobenzene in 10 ml of dichloromethane, then add 0.2 g of acetylphenylhydrazine and 0.3 g of o-benzoylsulfonimide and stir well , finally add 1 gram of cumene hydroperoxide and 0.25 gram of 1,4-hydroquinone, stir for 30 minutes, then vacuum process for 10 minutes under the condition of -0.08MPa, and then evenly coat the plastic plate for cutting. In the solvent recovery workshop, after the dichloromethane is evaporated and recovered, the glue is fixed on the plastic plate, packed with film, and applied by the client.

Embodiment 3

[0087] Completely dissolve 47.25 g of 4,4'-hexyl diacrylate-3-methylazobenzene in 10 ml of dichloromethane, then add 0.2 g of acetylphenylhydrazine and 0.3 g of o-benzoylsulfonimide and stir well Finally, add 0.5 g of polyurethane acrylic resin and 0.5 g of hydroxypropyl methacrylate, stir for 20 min, finally add 1 g of cumene hydroperoxide and 0.25 g of 1,4-hydroquinone, stir for 30 min, and then Vacuum treatment under MPa condition for 10min, and then evenly coated on the cutting plastic board, in the solvent recovery workshop, after the dichloromethane is evaporated and recovered, the glue is fixed on the plastic board, packed with film, and applied on the client side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com