Concrete-filled square steel tubular column reinforcing method based on high-ductility cement-based material

A technology of cement-based materials and concrete columns, applied in building maintenance, construction, building construction, etc., can solve problems such as poor high temperature resistance, fire resistance, occupied building area, large cross-sectional area, etc., to achieve good adaptability, Improve the bearing capacity and suppress the effect of drumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

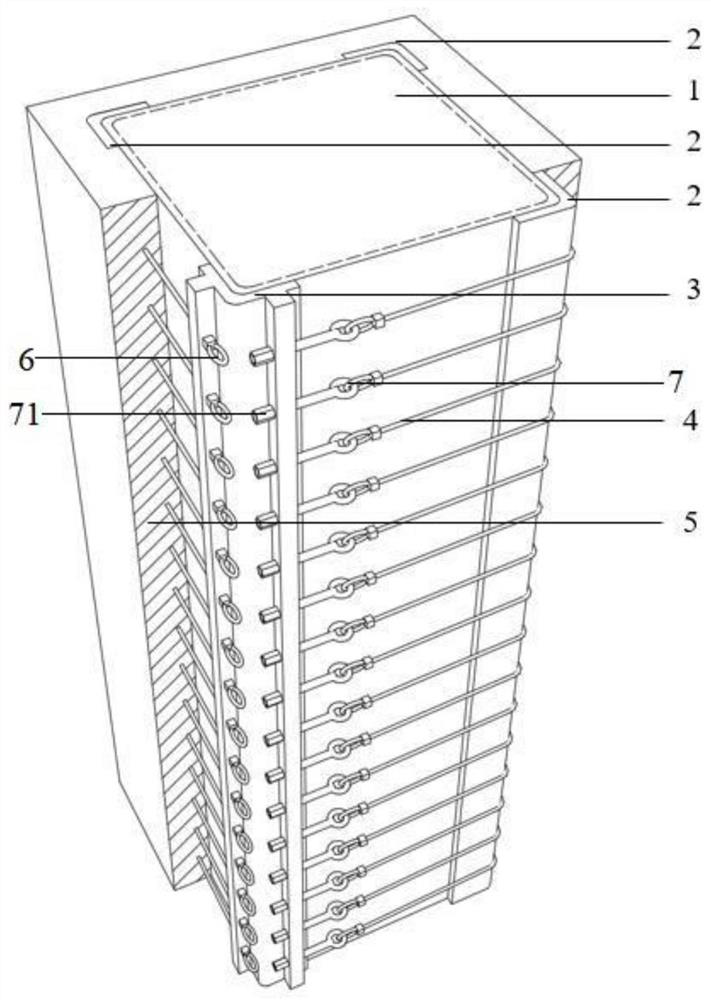

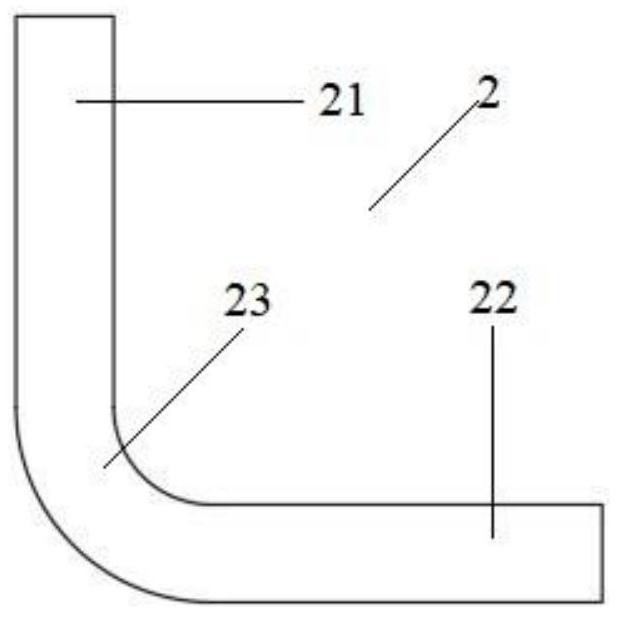

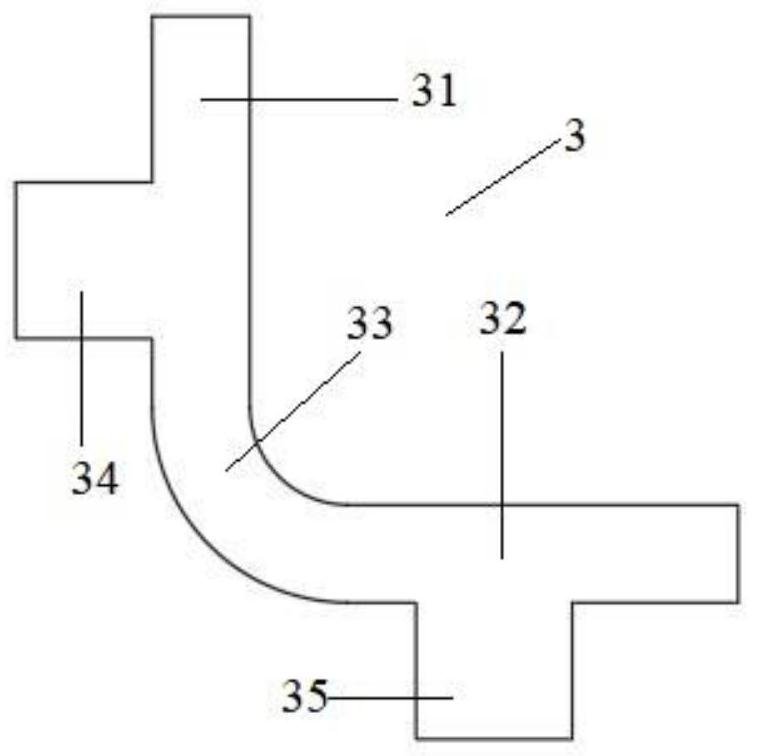

Embodiment 1

[0061] The thickness of the first reinforcement part 2 and the second reinforcement part 3 is 4 mm, wherein the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 30 mm. Steel strand 4 adopts high-strength steel strand 4, the diameter of steel strand 4 is 6mm, the tensile strength is 1860MPa, and the ultimate tensile strain is 2%. The distance between adjacent steel strands 4 in the steel strand network is 30mm. The prestress level of the stranded wire 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. High-ductility cement-based materials are made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducer, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: Water: PVA fiber: water reducer: accelerator = 1:2:1.2:0.05:0.9:0.05:0.01:0.01. The thi...

Embodiment 2

[0063] The thickness of the first reinforcement part 2 and the second reinforcement part 3 is 5 mm, wherein the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 36 mm. Steel strand 4 adopts high-strength steel strand 4. The diameter of steel strand 4 is 8mm, the tensile strength is 1770MPa, and the ultimate tensile strain is 2.5%. The distance between adjacent steel strands 4 in the steel strand network is 50mm. The prestress level of the stranded wire 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. High-ductility cement-based materials are made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducer, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: Water: PVA fiber: water reducer: accelerator = 1:0.8:1.2:0.02:0.5:0.04:0.008:0.01. Th...

Embodiment 3

[0065] The thickness of the first reinforcement part 2 and the second reinforcement part 3 is 5 mm, wherein the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 50 mm. The steel strand 4 adopts a high-strength steel strand 4, the diameter of the steel strand 4 is 15.2mm, the tensile strength is 2100MPa, and the ultimate tensile strain is 3%. The distance between the steel strand 4 in the steel strand net is 50mm. The prestress level of line 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. High-ductility cement-based composite is made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducing agent, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: Water: PVA fiber: water reducer: accelerator = 1:3:1.4:0.02:1.1:0.08:0.015:0.01. The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com