Preparation method of aluminum oxide anti-ion feedback film of micro-channel plate

An anti-ion feedback film and aluminum oxide technology, which is applied in the manufacture of secondary emitter electrodes, electron multiplier tubes, and light-emitting cathodes, can solve the problems of carbon pollution in microchannel plates, long time-consuming processes, etc. , to achieve the effects of avoiding pollution, avoiding high equipment investment costs and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

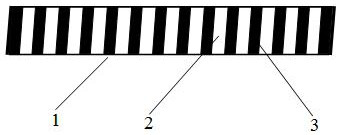

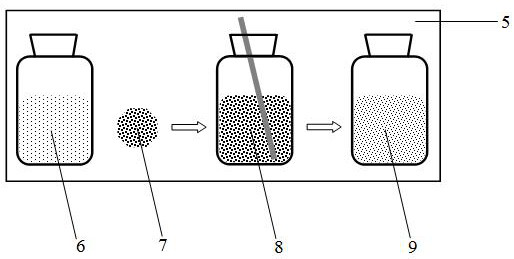

[0028] (1) In an environment with an ambient temperature of 20°C and a nitrogen atmosphere, use Ga 62.5 In 21.5 sn 16.0 Liquid alloy as a solvent, weighed 390 grams of Ga 62.5 In 21.5 sn 16.0 The liquid alloy is poured into a 100 ml large-mouth conical glass flask, and 4 grams of spherical aluminum powder with a diameter of 25 microns and a purity of 99.95% is added to Ga 62.5 In 21.5 sn 16.0 Formation of high-purity aluminum powder and Ga in liquid alloy 62.5 In 21.5 sn 16.0 Liquid alloy mixture, for high-purity aluminum powder and Ga 62.5 In 21.5 sn 16.0 The liquid alloy mixture was fully stirred for 12 minutes to obtain a gallium-based liquid alloy containing 1 wt% of aluminum.

[0029] (2) In an environment with an ambient temperature of 20°C and a nitrogen atmosphere, pour an appropriate amount of the gallium-based liquid alloy containing 1wt% aluminum obtained in step (1) into a clean glass petri dish with a diameter of 60 mm, and wait until it contains 1wt% ...

Embodiment 2

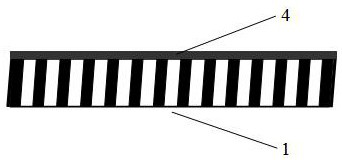

[0033] (1) Under the environment of ambient temperature 30℃ and nitrogen atmosphere, use Ga 75.5 In 24.5 Liquid alloy as a solvent, weighed 381 grams of Ga 75.5 In 24.5 The liquid alloy is poured into a 100 ml large-mouth conical glass flask, and 8 grams of spherical aluminum powder with a diameter of 25 microns and a purity of 99.95% is added to Ga 75.5 In 24.5 Formation of high-purity aluminum powder and Ga in liquid alloy 75.5 In 24.5 Liquid alloy mixture, for high-purity aluminum powder and Ga 75.5 In 24.5 The liquid alloy mixture was fully stirred for 15 minutes to obtain a gallium-based liquid alloy containing 2 wt% of aluminum.

[0034] (2) In an environment with an ambient temperature of 30°C and a nitrogen atmosphere, pour an appropriate amount of the gallium-based liquid alloy containing 2wt% aluminum obtained in step (1) into a clean glass petri dish with a diameter of 60 mm, and wait until it contains 2wt% aluminum After the shape of the gallium-based liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com