Transition metal phosphide/bismuth oxyhalide photocatalyst as well as preparation method and application thereof

A transition metal, bismuth oxyhalide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as fuel quality degradation, achieve no by-products, simple operation, and green desulfurization process mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides the preparation method of transition metal phosphide / bismuth oxyhalide photocatalyst described in the technical scheme, comprising the following steps:

[0038] (1) dissolving the bismuth salt and the halide salt in an alcoholic solvent, mixing the obtained mixed solution with an aqueous alkaline reagent solution, and performing a first hydrothermal reaction to obtain bismuth oxyhalide;

[0039] (2) Mix transition metal salt, phosphorus source, surfactant and alcohol-water mixed solvent, carry out second hydrothermal reaction, obtain transition metal phosphide;

[0040] (3) Mix the bismuth oxyhalide, transition metal phosphide and oxygen-containing reagent, and carry out liquid phase assembly to obtain transition metal phosphide / bismuth oxyhalide photocatalyst;

[0041] There is no chronological order restriction between said step (1) and step (2).

[0042] In the present invention, unless otherwise specified, all raw material components ...

Embodiment 1

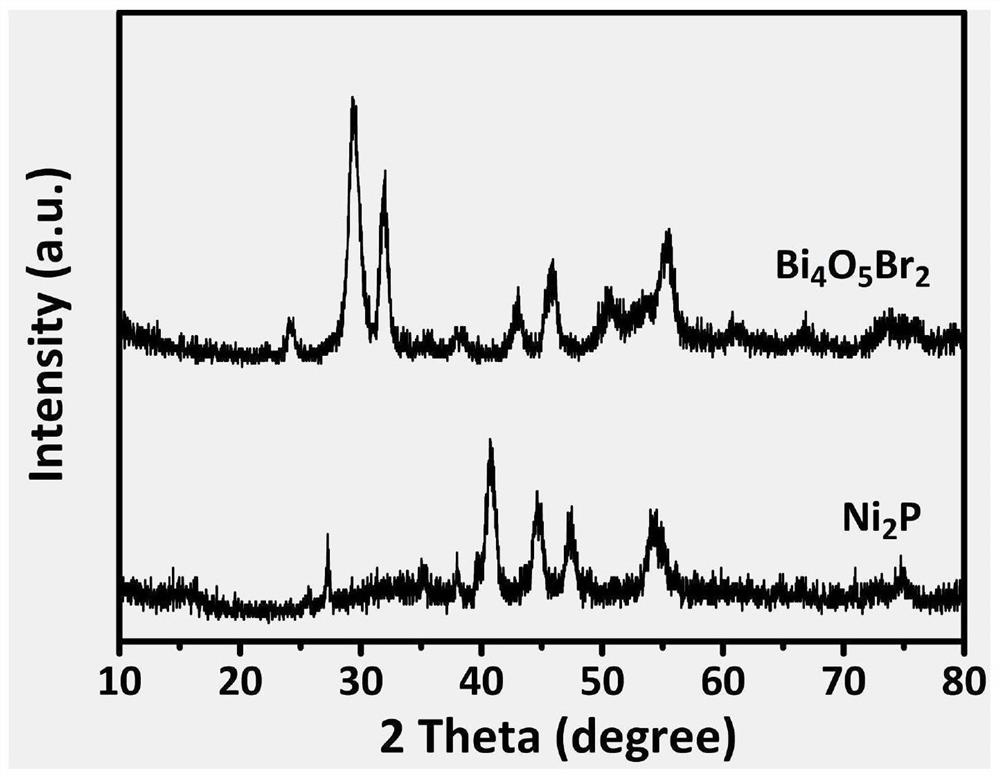

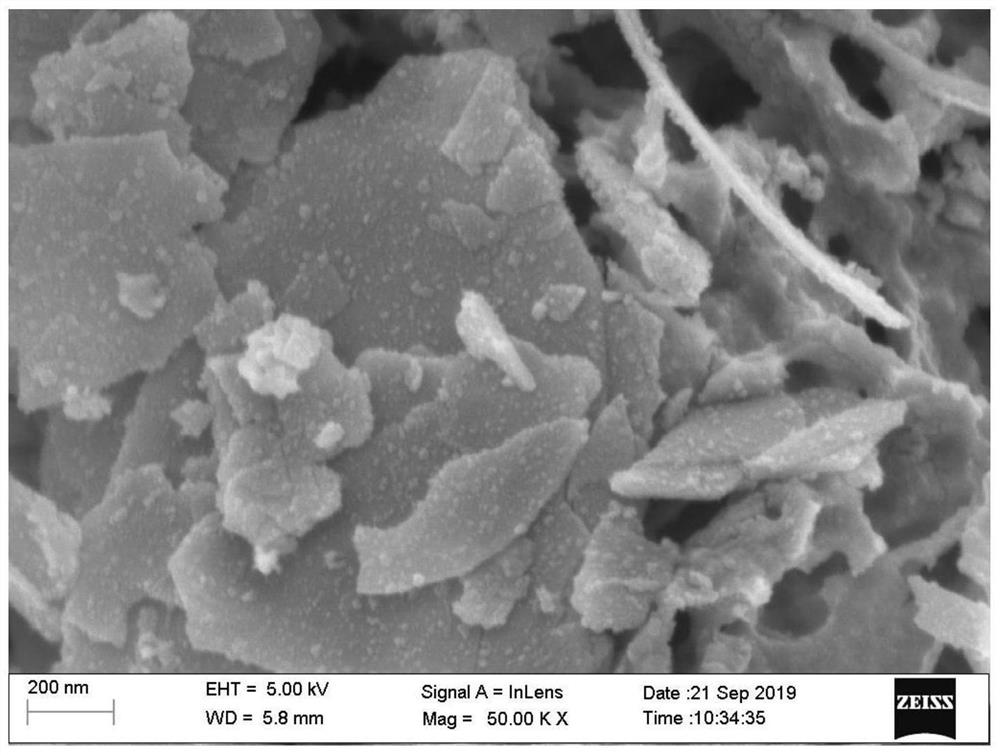

[0090] (1) 3mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 30mL of ethylene glycol and stirred for 30min, then 3mmolKBr was added and stirred for 30min, and 20mL of 12.5wt% ammonia solution was added dropwise and stirred for 2h; The first hydrothermal reaction was carried out at ℃ for 20 hours, the obtained reaction system was subjected to centrifugation, the obtained solid product was washed 3 times with water and 3 times with alcohol, and then vacuum-dried at 60 ℃ for 12 hours to obtain bismuth oxyhalide (Bi 4 o 5 Br 2 ).

[0091] (2) 1mmolNiCl 2 ·6H 2 O was dissolved in 50mL ethanol-water mixed solution (volume ratio of water and alcohol=1:1), and 8mmolNaH 2 PO 2 ·H 2 O, 0.1g CTAB and 0.15g SDBS, stirred and mixed for 30min, transferred the obtained mixed solution to a 100mL reaction kettle, carried out the second hydrothermal reaction at 140°C for 12h, centrifuged the obtained reaction system, and obtained the solid The product was washed 3 times with water and 3 times ...

Embodiment 2

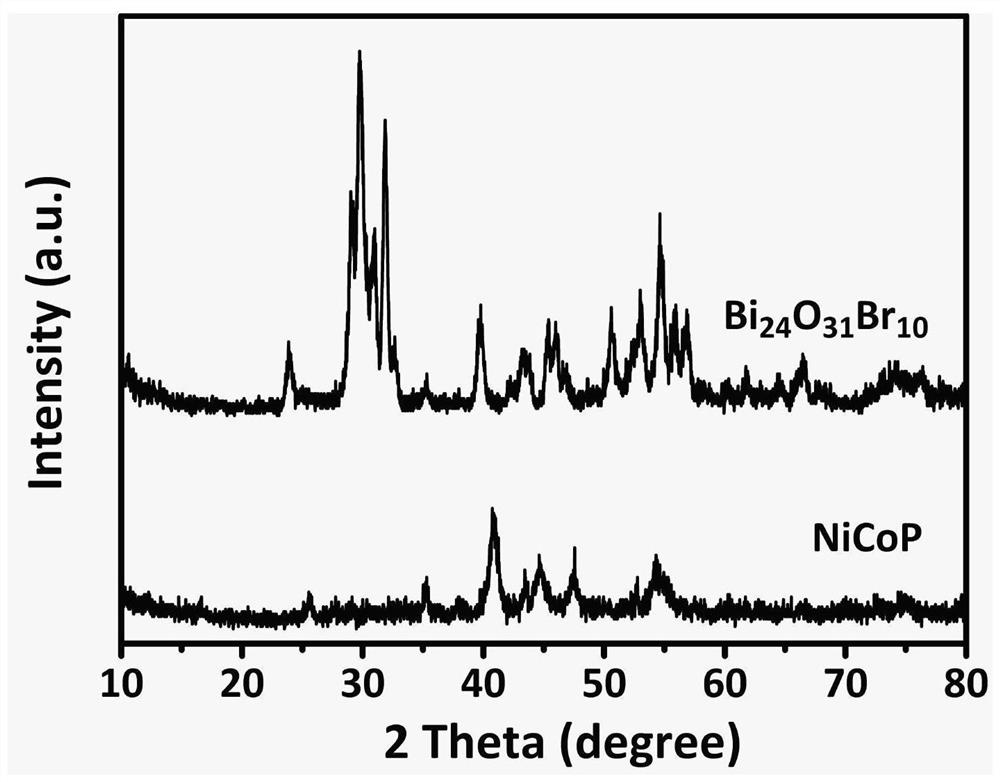

[0097] (1) 5mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 40mL of ethylene glycol and stirred for 30min, then 5mmolNaBr was added and stirred for 40min, 20mL of ammonia solution with a concentration of 15wt% was added dropwise and stirred for 3h; The first hydrothermal reaction was carried out under the conditions for 20 hours, the obtained reaction system was subjected to centrifugation, the obtained solid product was washed with water for 3 times and with alcohol for 3 times, and then vacuum-dried at 60°C for 12 hours to obtain bismuth oxyhalide (Bi 24 o 31 Br 10 ).

[0098] (2) 0.5mmolNiCl 2 ·6H 2 O, 0.5mmol CoCl 2 ·6H 2 O was dissolved in 50mL ethanol-water mixed solution (volume ratio of water and alcohol = 2:3), 15mmol red phosphorus, 0.1g CTAB and 0.1g SDBS were added, stirred and mixed for 30min, and the resulting mixture was transferred to a 100mL reaction kettle , carry out the second hydrothermal reaction at 200°C for 16h, centrifuge the obtained reaction syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com