A method for degrading organic pollutants by activating persulfate with carbonized polyaniline

A technology for activating persulfate and organic pollutants, used in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as complex equipment systems, avoid high energy consumption, improve degradation effect, Effects of excellent surface activity and electron transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the present invention, the preparation method of said carbonized polyaniline preferably comprises the following steps:

[0037] mixing aniline, hydrochloric acid aqueous solution and ammonium persulfate aqueous solution to carry out polymerization reaction to obtain polyaniline;

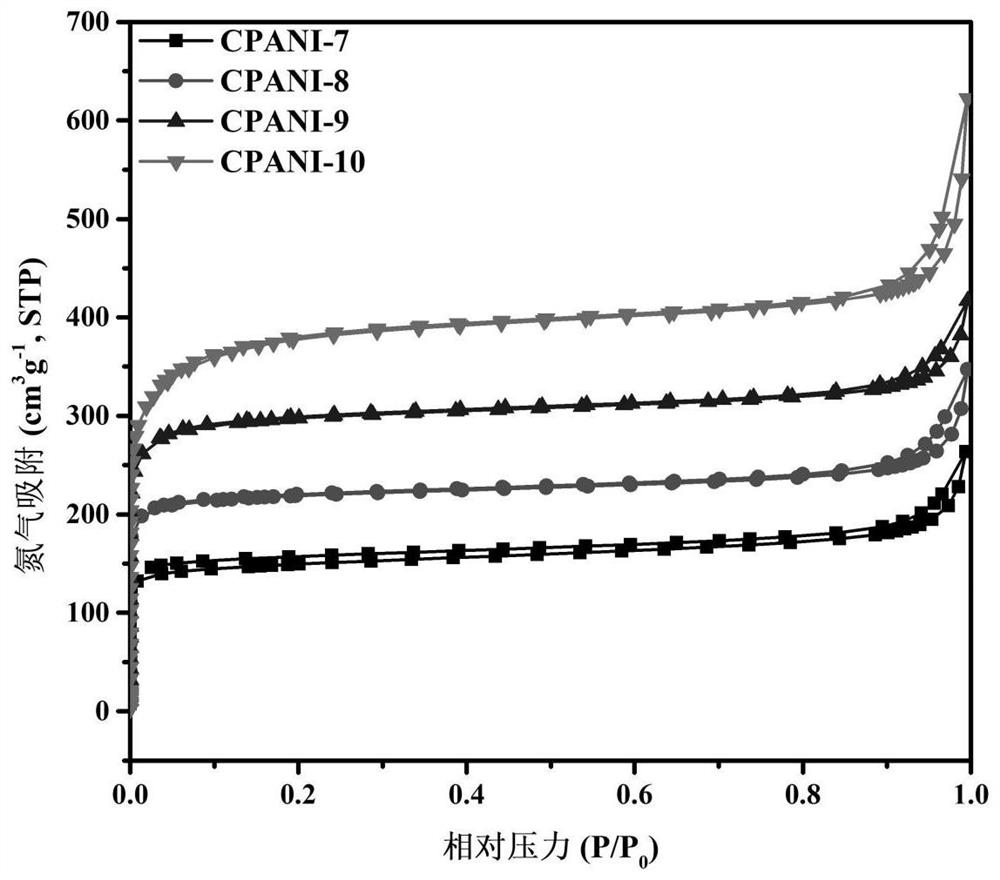

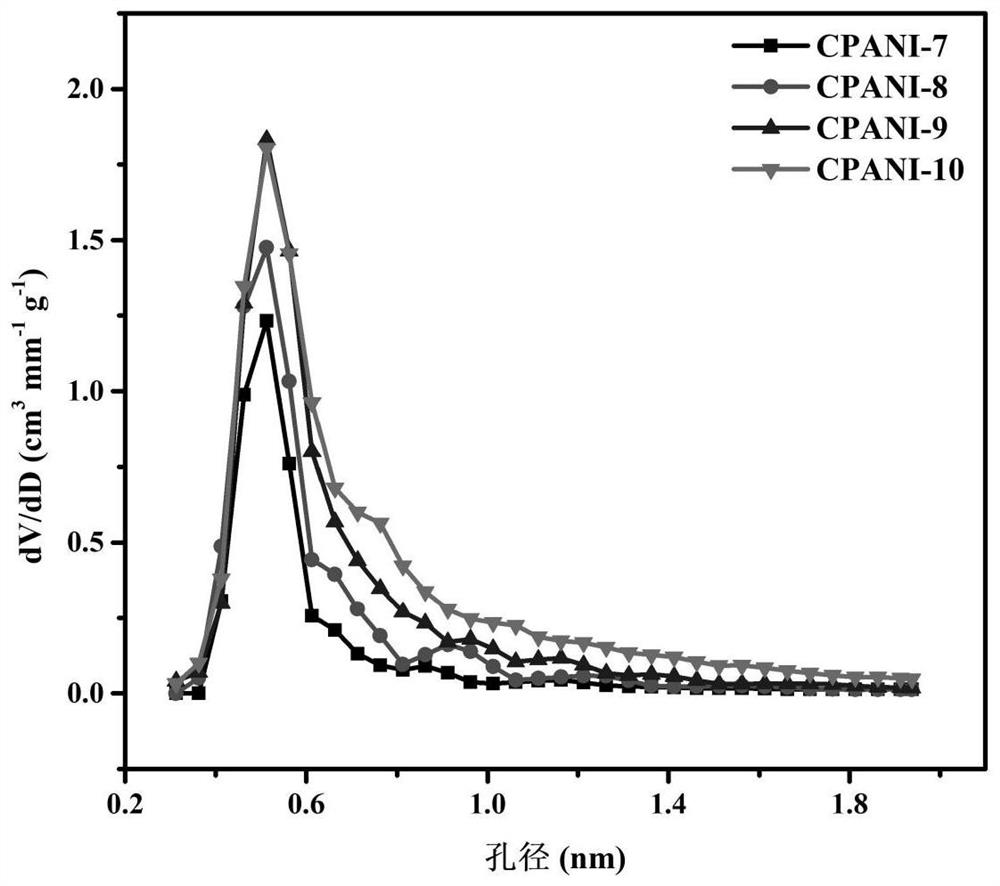

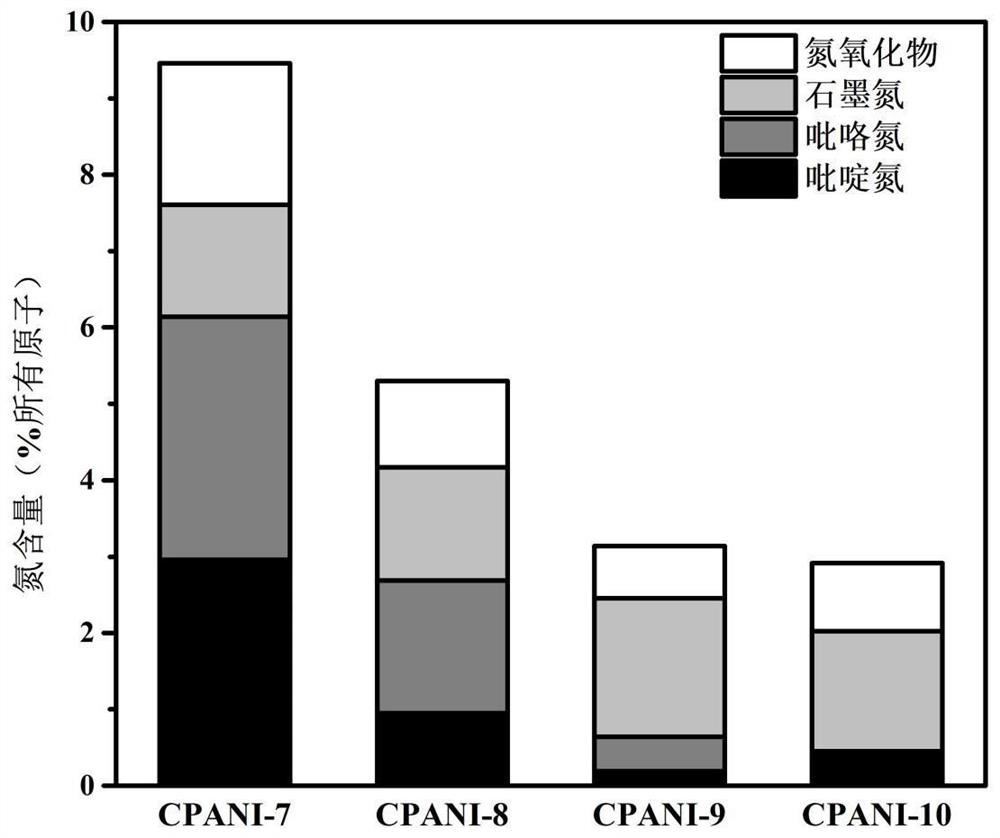

[0038] Under a protective atmosphere, the polyaniline is carbonized and then cooled to obtain carbonized polyaniline; the carbonization temperature is 700-1000° C., and the heating rate to the carbonization temperature is 1-5° C. / min.

[0039] The invention mixes aniline, hydrochloric acid aqueous solution and ammonium persulfate aqueous solution to carry out polymerization reaction to obtain polyaniline. In the present invention, the purity of the aniline is preferably ≥99.5%, and the aniline is preferably commercially available analytically pure aniline (with a concentration of 0.018 mol). In the present invention, the molar concentration of the hydrochloric acid aqueous solution is pref...

Embodiment 1

[0049] (1) According to the molar ratio of aniline and hydrochloric acid 1:2, 1.6mL of aniline (0.018mol, analytically pure, purity ≥ 99.5%) was dissolved in 100mL of 360mM hydrochloric acid aqueous solution and stirred for 0.5h as a monomer solution, and the obtained monomer solution was placed at 0 In an ice bath below ℃, add 100mL ammonium persulfate aqueous solution (180mM) according to the molar ratio of ammonium persulfate and aniline 1:1, and carry out the polymerization reaction for 4h; Wash the filter cake alternately with ultrapure water until the filtered solution is colorless; collect the solid, and then dry it in a vacuum oven at 60°C for 24 hours to obtain polyaniline;

[0050] (2) Place the polyaniline in a tube furnace, heat up to 900°C at a rate of 5°C / min under a nitrogen atmosphere, perform carbonization treatment for 4 hours, cool to room temperature at a rate of 1°C / min, and grind When the particle size reaches 350nm, carbonized polyaniline is obtained, wh...

Embodiment 2

[0053] The CPANI-9 obtained in Example 1 was added to 197 mL of an aqueous solution containing 2 mg / L sulfamethoxone, 197 mL of an aqueous solution containing 2 mg / L bezafibrate, and 197 mL of 2 mg / L ibuprofen at a concentration of 25 mg / L. In the aqueous solution, add 3mL potassium persulfate aqueous solution (10g / L) respectively in each aqueous solution sample again, the concentration of potassium persulfate in the gained reaction solution is 150mg / L, the pH of reaction solution is adjusted to 7 with NaOH , carry out degradation, and finally take samples and filter at regular intervals, and obtain the concentration of organic matter at a certain time through high-performance liquid chromatography detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com