Water-absorbent resin and preparation method thereof

A water-absorbing and resin technology, applied in the field of water-absorbing resin and its preparation, can solve the problems of not being able to obtain a water-absorbing resin with comprehensive performance balance, lack of liquid-passing performance, insufficient water-holding capacity, etc., and achieve excellent comprehensive performance, reduce dust pollution, The effect of high water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

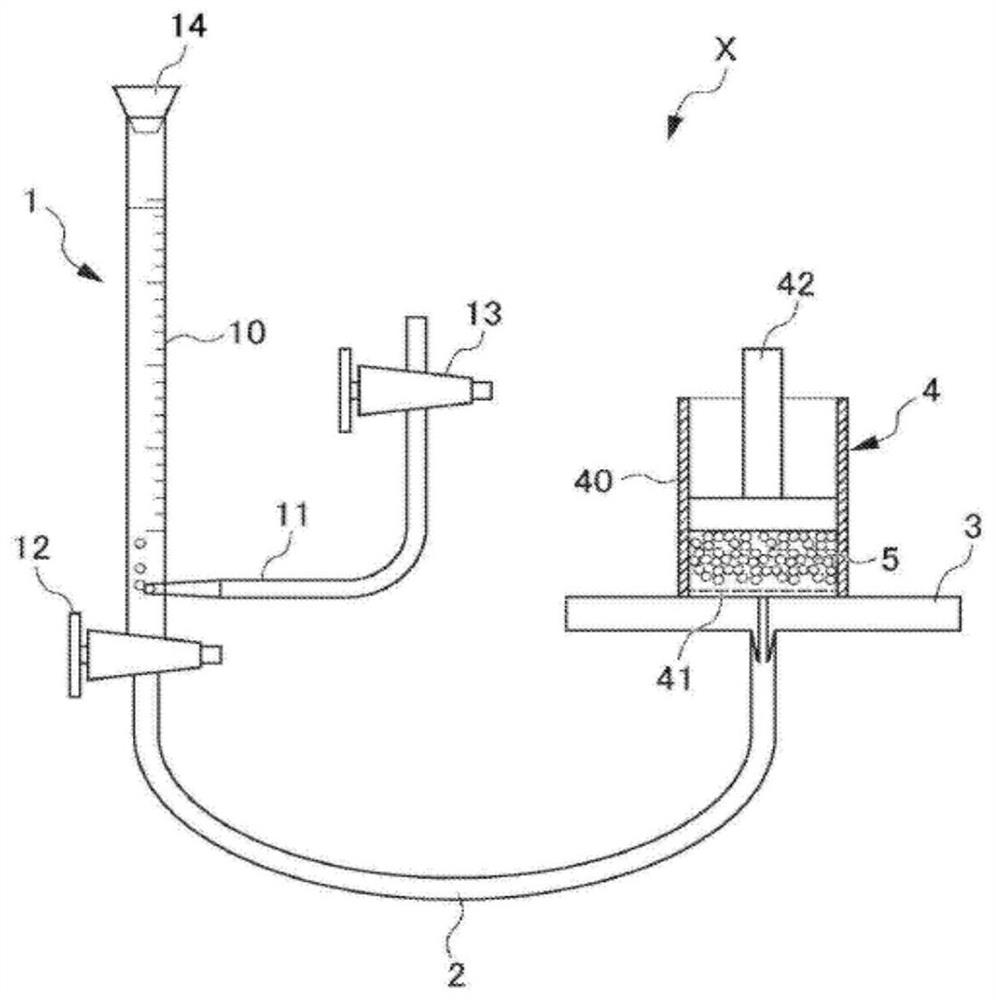

[0064] Preparation of aqueous epoxy dispersion A (step-by-step method):

[0065] Pour 800g of melted and dehydrated PEG6000 into the kettle, keep the temperature in the kettle at 80°C, then add 47g of hexahydrophthalic anhydride into the reaction kettle, raise the temperature to 100°C, react for about 3 hours, and take samples to test that the acid value reaches the theoretical value of 10mgKOH / g (by After NaOH back titration measurement, the same below), inject 210g of liquid epoxy resin E20, stir evenly, add 3.5g of triphenylphosphorus catalyst, react at a constant temperature of 130°C for 3 hours, and discharge the material after testing the acid value of -0.25mgKOH / g to prepare Reactive emulsifiers are obtained. Pour 450g of molten epoxy resin E20 into the dispersion kettle, maintain the temperature in the kettle at 100°C, then add 100g of the above-prepared active emulsifier and 100g of ethylene glycol dimethyl ether solvent, stir and mix at 800r / min for 20min; then cool ...

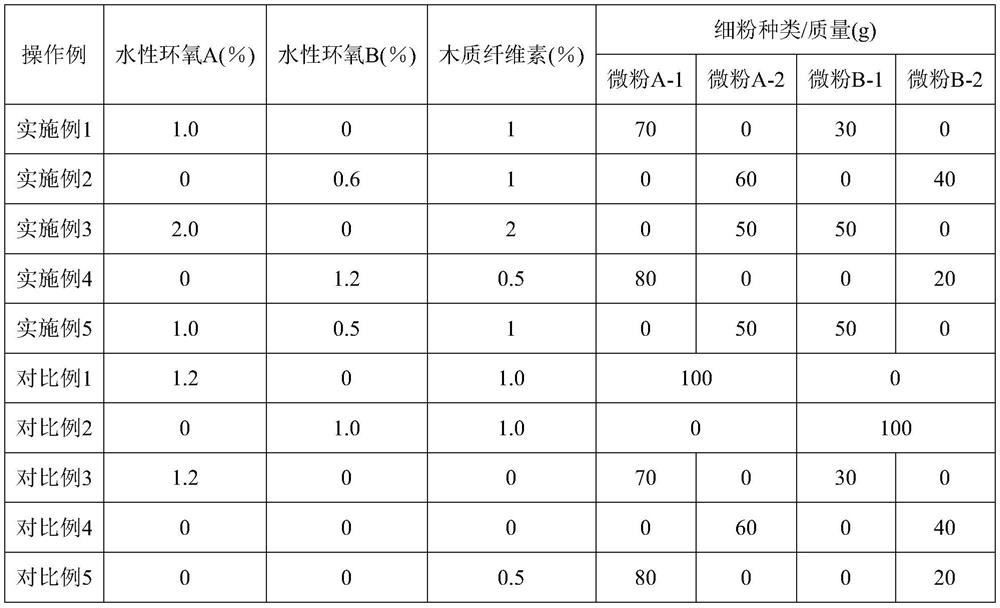

Embodiment 1

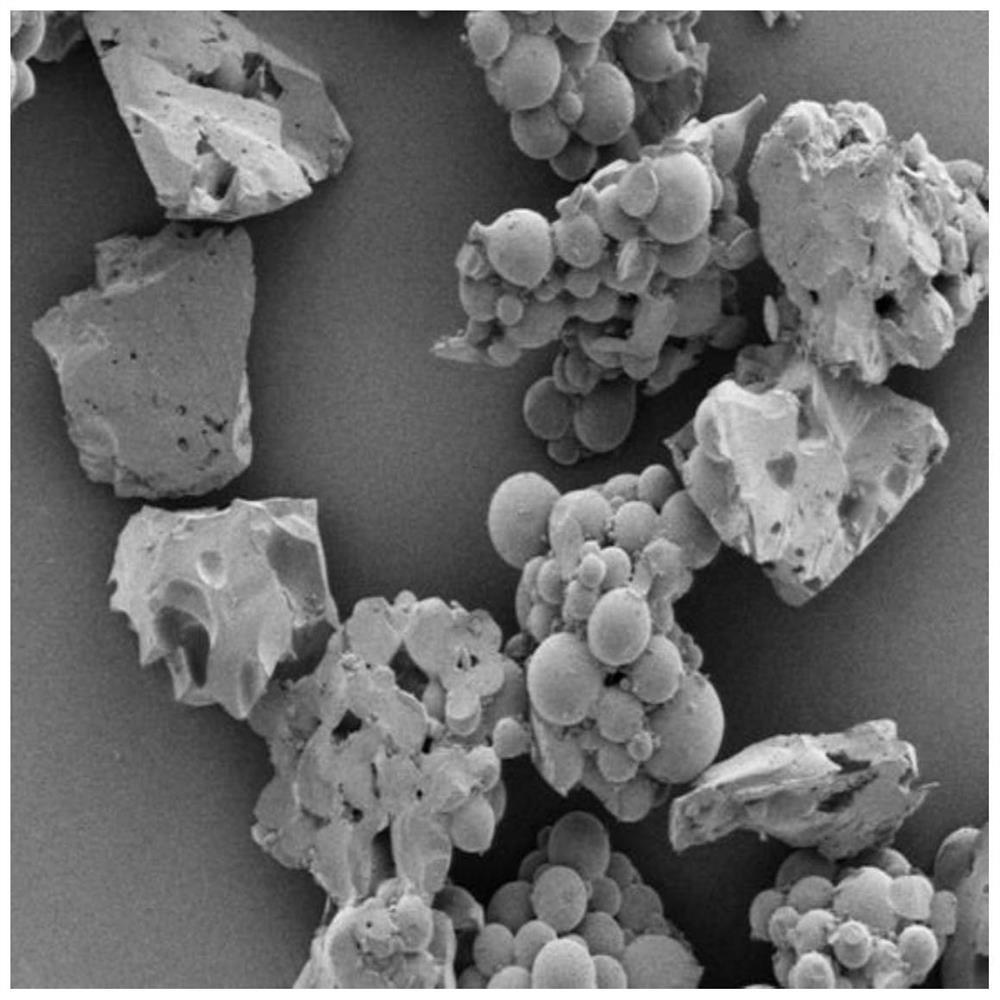

[0070] Mix 70g of micropowder A-1 and 30g of micropowder B-1 prepared by the two processes with 1.0g of lignocellulose, add 100g of deionized water containing 1% 1,3-propanediol to make it evenly swell and form a hydrogel Glue particles. The granulated hydrogel particles are dried at 210°C until the moisture content is lower than 3%. Then, the dried water-absorbing resin particles are ground and sieved to obtain a raw powder with a particle size distribution of 150-850 microns. Finally, spray evenly water-based epoxy dispersion A which accounts for 1.0% of the total mass of the two micropowders to the obtained raw powder to make it uniformly dispersed and adsorbed, and dry at 130°C for 1 hour to obtain a finished product with special appearance and properties .

Embodiment 2

[0072] Mix 60g of micropowder A-2 and 40g of micropowder B-2 prepared by the two processes with 1.0g of lignocellulose, add 100g of deionized water containing 2% of 1,4-butanediol to make it evenly swell and form Hydrogel particles. The granulated hydrogel particles are dried at 210°C until the moisture content is lower than 3%. Then, the dried water-absorbing resin particles are ground and sieved to obtain a raw powder with a particle size distribution of 150-850 microns. Finally, evenly spray 0.6% of the total mass of the two micropowders into the obtained raw powder with water-based epoxy dispersion B to make it uniformly dispersed and adsorbed, and dry at 130°C for 1 hour to obtain a finished product with special appearance and properties .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com