Reflective heat-insulation waterproof coating and preparation method and application thereof

A technology of waterproof coatings and heat insulation materials, applied in the direction of reflection/signal coatings, coatings, building insulation materials, etc., can solve the problems of single variety and function, low heat insulation performance, etc., to achieve blocking heat conduction and high bonding strength , The effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

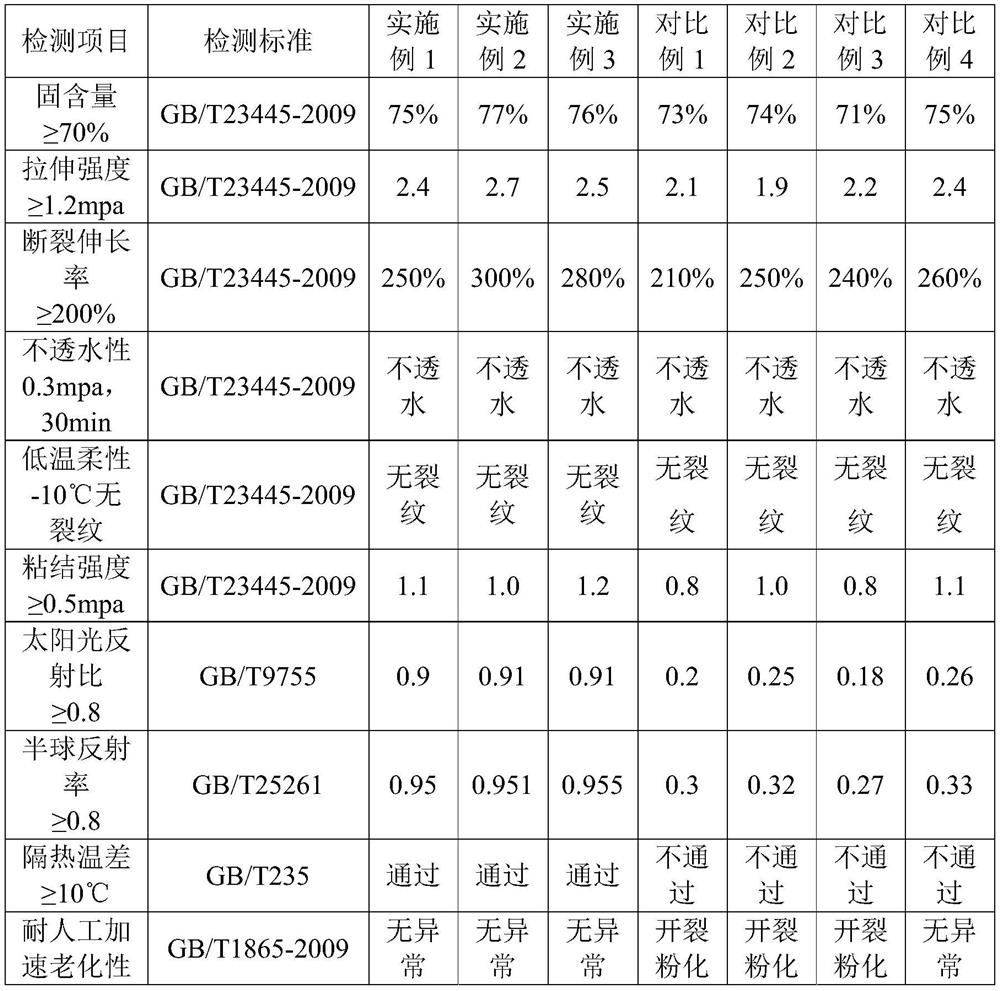

Examples

Embodiment 1

[0043] Waterproof coating with reflective heat insulation (parts by weight)

[0044] Material A components: 98.6 parts of silicone acrylic emulsion, 0.1 part of AMP-95 multifunctional additive, 10.3 parts of vegetable oil defoamer AGITAN, 1 part of glycerin.

[0045]B material components: 35 parts of 425 white Portland cement, 10 parts of rutile titanium dioxide, 7 parts of infrared reflective titanium dioxide, 10 parts of heavy calcium carbonate, 8 parts of solid ceramic microbeads, and 30 parts of ultra-white quartz sand.

Embodiment 2

[0047] Waterproof coating with reflective heat insulation (parts by weight)

[0048] Material A components: 98.5 parts of silicone acrylic emulsion, 0.1 part of AMP-95 multifunctional additive, 0.4 parts of silicone defoamer AGITAN 7666, 1 part of ethylene glycol.

[0049] Material B components: 39 parts of 425 white Portland cement, 15 parts of rutile titanium dioxide, 7 parts of infrared reflective titanium dioxide, 14 parts of heavy calcium carbonate, 5 parts of solid ceramic microbeads, and 20 parts of ultra-white quartz sand.

Embodiment 3

[0051] Waterproof coating with reflective heat insulation (parts by weight)

[0052] Material A components: 98.5 parts of silicone acrylic emulsion, 0.15 parts of AMP-95 multifunctional additive, 0.2 parts of vegetable oil defoamer AGITAN271, 0.15 part of silicone defoamer AGITAN 766, and 1 part of ethylene glycol.

[0053] B material components: 41 parts of 425 white Portland cement, 10 parts of rutile titanium dioxide, 10 parts of infrared reflective titanium dioxide, 8 parts of heavy calcium carbonate, 8 parts of solid ceramic microbeads, and 23 parts of ultra-white quartz sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com