Composite lithium ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of cycle performance cycle performance, reduce battery volume energy density, tap density and compaction density Low-level problems, to achieve the effect of improving rate performance, high compaction density, and improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

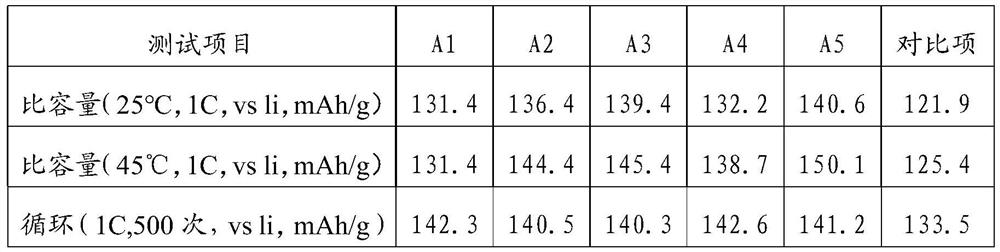

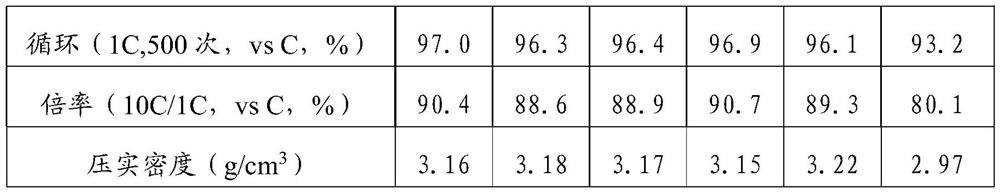

Examples

Embodiment 1

[0023] Embodiment 1: Composite lithium-ion battery cathode material and preparation method thereof

[0024] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm~20.0μm, and the distribution width of spinel-type lithium manganate is less than 1.0, that is, [(D90-D10) / D50]<1.0, layered nickel-manganese binary material The laser particle size is 2.0μm~5.0μm.

[0025] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0026] (1) Preparation of trimanganese tetraoxide: Take a certain amount of deionized water and add it to the reaction kettle as the bottom liquid, turn on the stirring and heating de...

Embodiment 2

[0033] Embodiment 2: Composite lithium-ion battery cathode material and preparation method thereof

[0034] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm-20.0μm, the distribution width of spinel-type lithium manganate is less than 1.0, and the laser particle size of layered nickel-manganese binary material is 2.0μm-5.0μm.

[0035] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0036] (1) The preparation of trimanganese tetroxide is the same as in Example 1.

[0037] (2) The preparation of spinel type lithium manganate is the same as in Example 1, and the prepared spinel type lithium ...

Embodiment 3

[0043] Embodiment 3: Composite lithium-ion battery cathode material and preparation method thereof

[0044] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm-20.0μm, the distribution width of spinel-type lithium manganate is less than 1.0, and the laser particle size of layered nickel-manganese binary material is 2.0μm-5.0μm.

[0045] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0046] (1) The preparation of trimanganese tetroxide is the same as in Example 1.

[0047] (2) The preparation of spinel type lithium manganate is the same as in Example 1, and the prepared spinel type lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com