Polypropylene resin for electric wire insulation

A resin, propylene technology, used in insulators, insulated cables, insulated conductors, etc., can solve the problems of reduced powder production stability, local physical property deterioration, unevenness, etc., to achieve excellent windability, excellent production stability, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

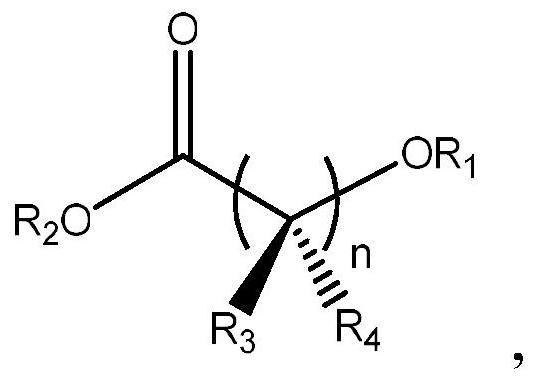

[0036] The preparation method of the ethylene-propylene block copolymer of the present invention is not particularly limited, and the preparation method of the ethylene-propylene block copolymer known in the technical field of the present invention can be directly used, or used after being appropriately modified.

[0037] Preferably, the Hypol process of Mitsui Corporation, which enables continuous polymerization by connecting 2 bulk reactors and 2 gas phase reactors in series, can be used to prepare ethylene according to polymerization methods known to those skilled in the art - Propylene block copolymers.

[0038] Specifically, in the first-stage to third-stage reactors, a propylene homopolymer may be prepared by feeding propylene alone, or an ethylene-propylene random copolymer may be prepared by additionally feeding ethylene. In the polymerization reaction of the ethylene-propylene random copolymer, an equal amount of ethylene can be copolymerized in each polymerization re...

Embodiment 1 to Embodiment 4

[0055] In a glass reactor equipped with a 1-liter stirrer fully replaced by nitrogen, add 112 ml of toluene and 15 g of diethoxymagnesium (spherical with an average particle size of 20 μm, a particle size distribution index of 0.86, and an apparent density of 0.35g / ml), and maintained at a temperature of 10°C, dilute 20ml of titanium tetrachloride in 30ml of toluene and add it to the reactor for 1 hour, then raise the temperature of the reactor to 100°C, and add A mixture of 3.6 g diisobutyl phthalate, 1.4 g methyl 4-methoxybutyrate. After keeping at 100° C. for 2 hours, lower the temperature to 90° C., stop stirring, remove the supernatant, and then wash once with 200 ml of toluene. 120 ml of toluene and 20 ml of titanium tetrachloride were added thereto, the temperature was raised to 100° C. and maintained for 2 hours, and this process was repeated once. After the aging process, the slurry mixture was washed twice with 200 ml of toluene each time, and washed five times with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com