Preparation process of monochlorodifluoromethane

A technology for difluoromonochloromethane and a preparation process is applied in the field of preparation of difluoromonochloromethane, and can solve the problems of poor product selectivity of difluoromonochloromethane, complicated separation and purification process of trifluoromethane, low conversion rate and the like, Achieve the effect of improving selectivity, improving catalyst performance, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The main catalyst is prepared by impregnation method: the nitrate of the active component Al is stirred and dissolved with deionized water to obtain a metal salt solution, that is, the impregnation solution; the dried multi-level micro / mesoporous Cr 2 o 3 The carrier was impregnated in the impregnating solution for 4 hours at room temperature, then filtered, and dried in a drying oven at 114°C for 8 hours to obtain a precursor. Finally, the obtained precursor was calcined under inert gas argon, and calcined at 500°C for 4 hours to obtain the main catalyst. Among them, the multi-level micro / mesoporous Cr 2 o 3 The specific surface area is 86.5m 2 / g, the average pore diameter is 9.5nm, 55.2% of the pore diameter is 0.2-2nm, and 14.5% of the pore diameter is 15-50nm.

[0056] By physically grinding and mixing with the host catalyst, adding metal doping components 2wt% Ru and rare earth additives 5wt% Sm 2 o 3 , 1wt% SmCl 3 , the added amount is based on the mass of ...

Embodiment 2

[0059] The main catalyst is prepared by impregnation method: the sulfate salt of the active component Mg is stirred and dissolved in deionized water to obtain a metal salt solution, that is, the impregnation solution; the dried multi-level micro / mesoporous Cr 2 o 3Immerse in the impregnating solution for 4 hours at room temperature, then filter, put in a drying oven and dry at 114°C for 8 hours to obtain a precursor. Finally, the obtained precursor is calcined under inert gas argon, and calcined at 500°C for 4 hours to obtain the main catalyst. Among them, the multi-level micro / mesoporous Cr 2 o 3 The specific surface area of the carrier is 85.8m 2 / g, the average pore diameter is 9.5nm, 55.2% of the pore diameter is 0.2-2nm, and 14.5% of the pore diameter is 15-50nm.

[0060] By physically grinding and mixing with the main catalyst, adding the metal doping component 2wt% Pd and the rare earth additive 3wt% La 2 o 3 , 2wt% LaCl 3 , the added amount is based on the mass...

Embodiment 3

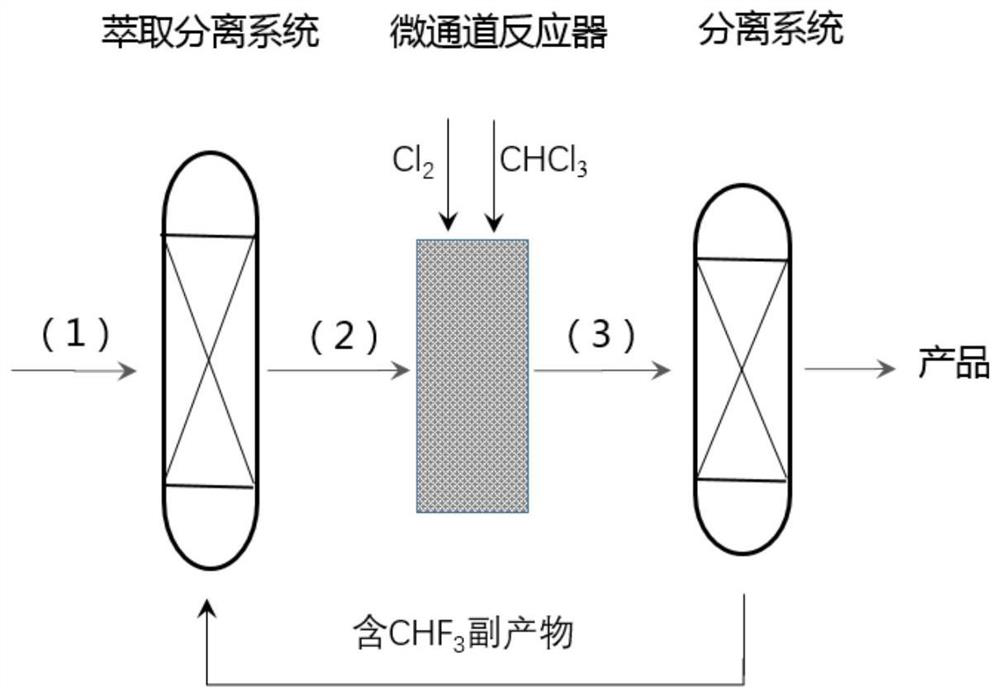

[0079] Trifluoromethane, chloroform and chlorine are raw materials to produce difluorochloromethane product, comprising the following steps:

[0080] In step 1), the mixed gas (1) containing trifluoromethane by-products is sent into an extraction separation tower, and high-purity trifluoromethane gas (2) is obtained after purification, and the extract in the extraction separation tower is pyridine tetrafluoroboron acid salt; step 2), the high-purity trifluoromethane gas (2) is sent into a microchannel reactor as a reaction raw material, and chloroform and chlorine are added, and the reaction is carried out in the presence of the catalytic system of Example 1 to obtain a microchannel reactor containing The reaction product flow (3) of difluorochloromethane, the reactor heating temperature is 230 ℃, and the mol ratio of trifluoromethane, trichloromethane and chlorine is 3:0.6:1; step 3), will contain difluorochloromethane The reaction product stream (3) of methane is sent into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com