Flexible conductive composite material with nano net-shaped and flower-shaped structure as well as preparation method and application thereof

A flower-like structure, flexible conductive technology, applied in the direction of material analysis, structural parts, and analysis materials through electromagnetic means, can solve the problems of unfavorable carrier migration, transconductance value needs to be improved, and difficult conductive paths of nanoflower structure. To achieve the effect of enriching active sites, high specific surface area, and increasing the amount of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

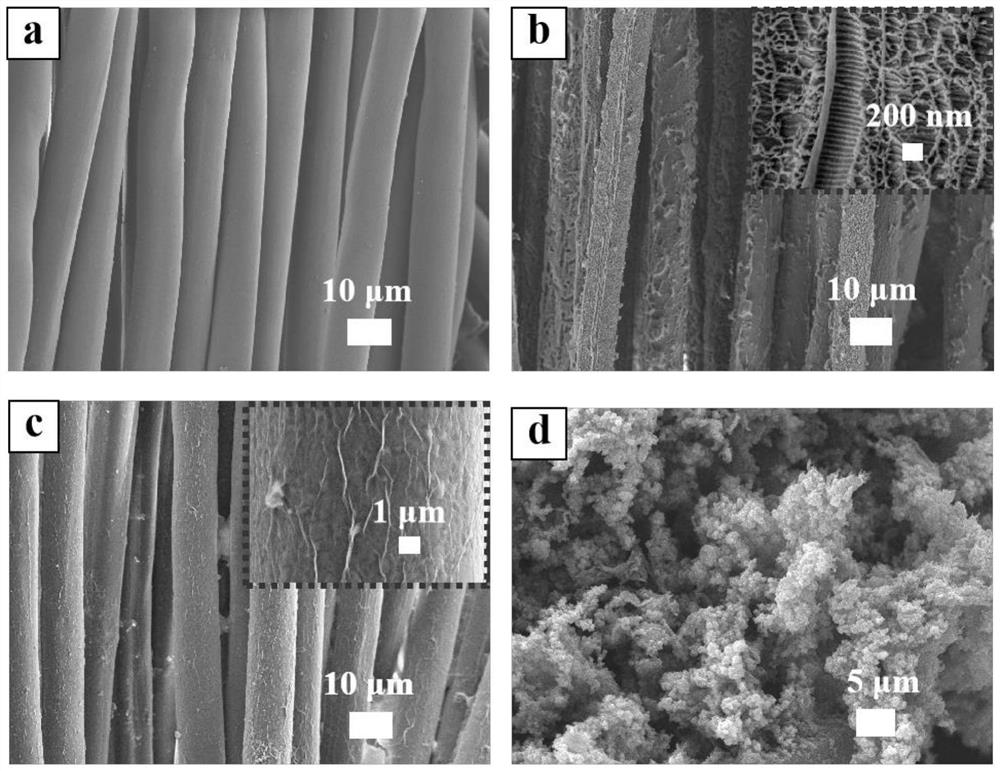

[0046] A flexible conductive composite material with a nano-network and flower-like structure, the preparation method of which is as follows:

[0047] S1. Disperse the single-layer graphene oxide powder in deionized water, and use a cell crushing instrument to ultrasonically treat it for 1.5-8 hours at a temperature of 0°C to obtain a 5 mg / mL single-layer graphene oxide nanosheet solution; soak the cotton yarn In the single-layer graphene oxide solution, vibrate or ultrasonic for 0.5-12h, the oscillation speed is 100-200r / min, and obtain the cotton yarn (GO / cotton yarn) loaded with graphene oxide nanosheets;

[0048] S2. Under the power of 100W, place the wet GO / cotton yarn obtained in step S1 in the CVD vapor deposition chamber, and continuously feed a mixed gas with a volume fraction ratio of 85%: 15% nitrogen and hydrogen, and the reduction reaction Take it out after 1h, and obtain the RGO / cotton yarn with fluffy scale and groove structure on the surface;

[0049] Using an...

Embodiment 2

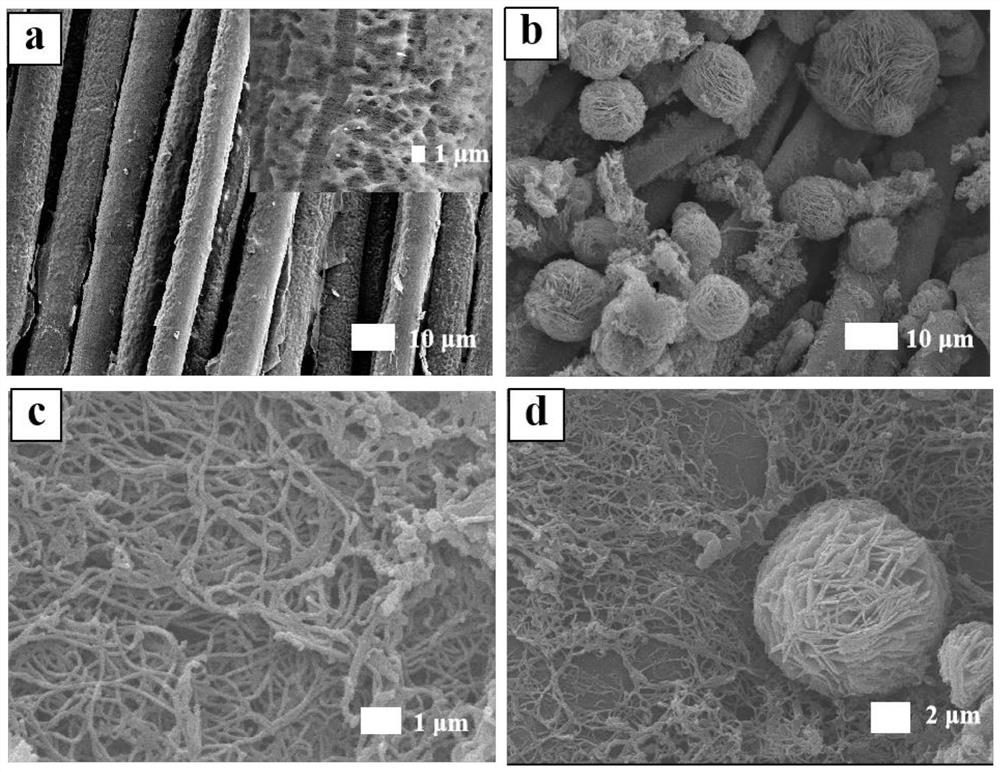

[0052] A flexible conductive composite material with a nano-network and flower-like structure, its preparation method is compared with Example 1, the difference is that in step S1, the flexible substrate is before loading the graphene oxide nanosheets , the plasma sputtering pretreatment is performed first, as follows:

[0053] S11. Place the cotton yarn in the plasma sputtering chamber, when the air pressure in the chamber reaches 1×10 -2 ~8×10 -2 At mbar, a mixed gas composed of 85% by volume fraction: 15% of nitrogen and hydrogen is introduced, and atomized deionized water is introduced at the same time. When the chamber pressure reaches 1×10 -1 ~3×10 -2 At mbar, process the sample for 15 minutes at a power of 100W; stop feeding deionized water, and continue to process the sample for 15 minutes with a mixed gas composed of nitrogen and hydrogen with a volume fraction ratio of 85%:15%, and obtain a cotton yarn with a groove structure on the surface (plasma / cotton yarn); ...

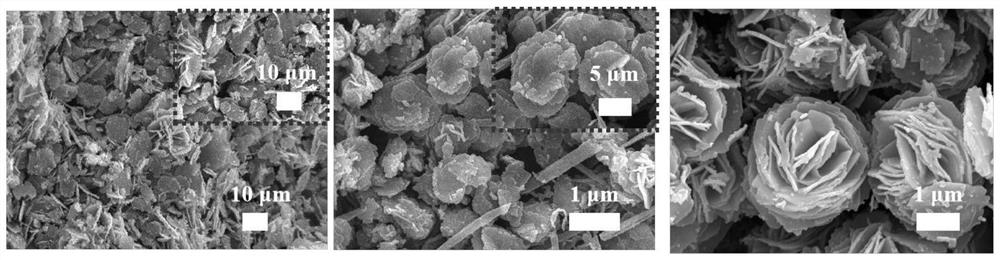

Embodiment 3~6

[0067] A flexible conductive composite material with a nano-network and flower-like structure, its preparation method is compared with Example 2, the difference is that in step S2, the volume fraction ratio of nitrogen and hydrogen is shown in Table 2. Others are substantially the same as those in Embodiment 2, and will not be repeated here.

[0068] Preparation conditions and transistor transconductance value of table 2 embodiment 3~6

[0069] Example The volume fraction ratio of nitrogen and hydrogen 3 50%:50% 4 80%:20% 5 90%:10% 6 99%:1%

[0070] The experimental results show that by adjusting the ratio of nitrogen and hydrogen in the reducing gas, the amount of nitrogen doping in the reduced graphene oxide obtained by gas phase reduction can be adjusted. The structure and electrical properties of composite materials have a certain influence. In actual operation, the composition of the gas-phase reducing atmosphere can be specifically r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com