Preservation processing method of rice

A processing method and rice technology, which are applied in the fields of edible seed preservation, food preservation, and heat preservation of seeds, etc., can solve the problems of direct damage to microorganisms and pests, unfavorable long-term storage of rice, accelerated metabolism of nutrients, etc., and achieve strong free radical scavenging. Ability, improve affinity and binding force, improve the effect of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

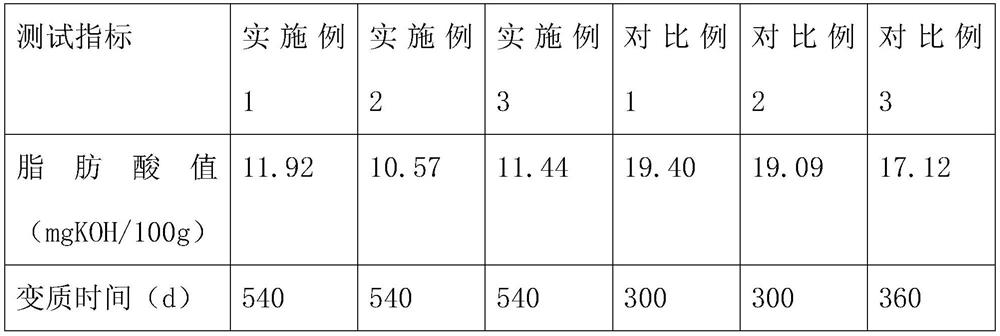

Examples

Embodiment 1

[0021] A fresh-keeping processing method for rice, comprising the following steps:

[0022] S1. Dry the husked and peeled rice until the water content is 10%, and then perform the first ultraviolet irradiation treatment, the irradiation wavelength is 230nm, and the irradiation intensity is 90W / m 2 , the irradiation time is 20min, and the pretreated rice is obtained;

[0023] S2, first adding chitosan, hydrolyzed collagen and fructooligosaccharides into the acetic acid solution with a mass fraction of 0.5% dissolves completely, then adopts a micro-jet homogenizer to carry out dynamic high-pressure micro-jet treatment under the condition of 100MPa, and the number of treatments is The number of times is 3 times to obtain a composite preservation solution, wherein the massfraction of chitosan is 0.5%, the massfraction of hydrolyzed collagen is 1%, and the massfraction of fructooligosaccharide is 0.5%;

[0024] S3. Spray the composite fresh-keeping solution evenly into the pretrea...

Embodiment 2

[0027] A fresh-keeping processing method for rice, comprising the following steps:

[0028] S1. Dry the husked and peeled rice until the water content is 13.5%, and then perform the first ultraviolet irradiation treatment, the irradiation wavelength is 240nm, and the irradiation intensity is 100W / m 2 , the irradiation time is 25min, and the pretreated rice is obtained;

[0029] S2, first adding chitosan, hydrolyzed collagen and fructooligosaccharides into the acetic acid solution with a mass fraction of 1% dissolves completely, then adopts a micro-jet homogenizer to carry out dynamic high-pressure micro-jet treatment under the condition of 120MPa, and the number of treatments is The number of times is 5 times to obtain a composite preservation solution, wherein the massfraction of chitosan is 0.9%, the massfraction of hydrolyzed collagen is 1.5%, and the massfraction of fructooligosaccharide is 0.6%;

[0030] S3. Spray the composite preservative solution evenly into the pretr...

Embodiment 3

[0033] A fresh-keeping processing method for rice, comprising the following steps:

[0034] S1. Dry the husked and peeled rice until the water content is 15%, and then perform the first ultraviolet irradiation treatment, the irradiation wavelength is 260nm, and the irradiation intensity is 120W / m 2 , the irradiation time is 30min, and the pretreated rice is obtained;

[0035] S2, first adding chitosan, hydrolyzed collagen and fructooligosaccharides into the acetic acid solution with a mass fraction of 2% dissolves completely, then adopts a micro-jet homogenizer to carry out dynamic high-pressure micro-jet treatment under the condition of 140MPa, and the number of treatments is The number of times is 6 times to obtain a composite preservation solution, wherein the massfraction of chitosan is 1%, the massfraction of hydrolyzed collagen is 2%, and the massfraction of fructooligosaccharide is 1%;

[0036] S3. Spray the composite preservative solution evenly into the pretreated ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com