Modular railway train excrement collector excrement wastewater treatment method

A treatment method and fecal wastewater technology, applied in chemical instruments and methods, water/sewage treatment, anaerobic digestion treatment, etc., to achieve the effect of solving insufficient space, efficient and fast wastewater treatment, and increasing the number of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Taking a distribution center of a high-speed railway station in Kunming, Yunnan Province as an example, because it is a key transportation hub and there are many trains at the station, the concentration of fecal waste water in the high-speed railway toilet collector is high and the water volume is large. The waste water from the toilet is extracted by the vacuum system and placed in the septic tank. The effluent COD of the septic tank is 5800mg / L, the SS is 2650mg / L, the ammonia nitrogen is 1500mg / L, the total nitrogen is 1800mg / L, and the total phosphorus is 200mg / L.

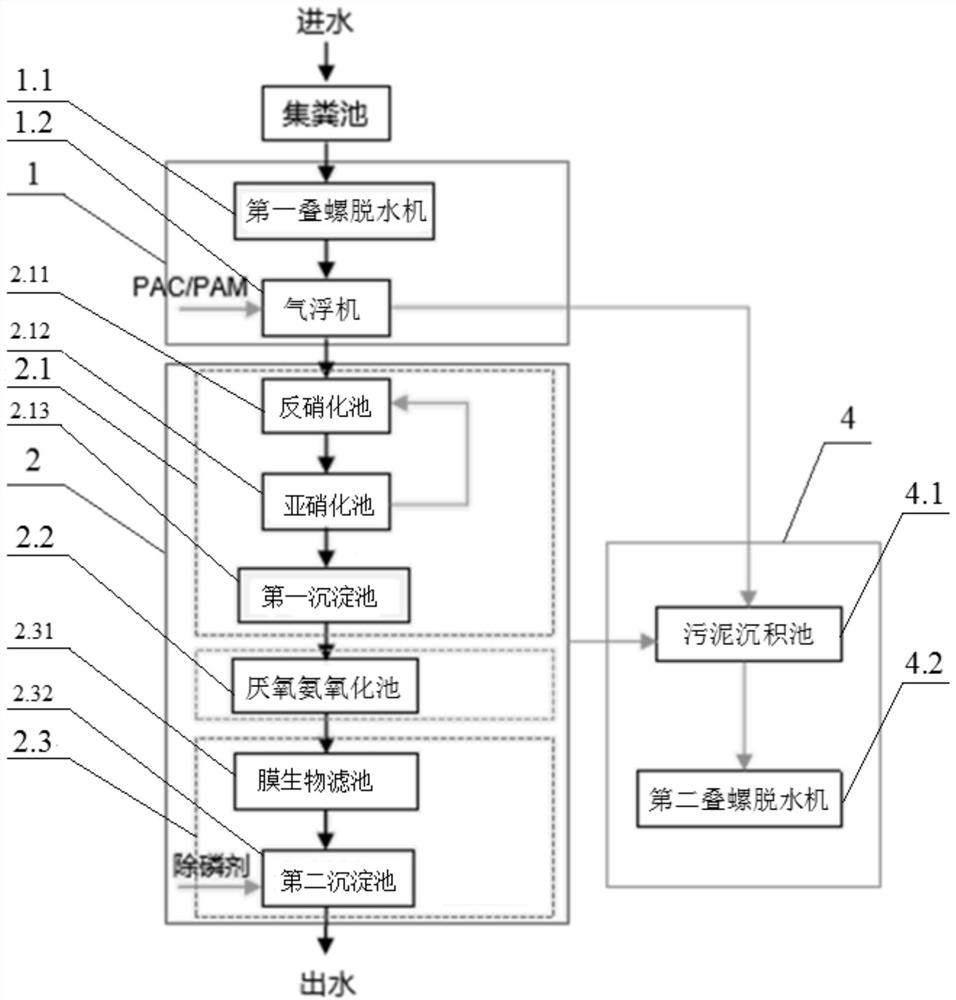

[0044] like figure 1 As shown, the sewage goes through the pretreatment system → nitrogen and phosphorus removal system, and the sludge generated during the sewage treatment process enters the sludge treatment system. The specific treatment steps are as follows:

[0045] Pharmacy configuration; respectively prepare 25% polyaluminum chloride and 0.2% polyacrylamide solutions for use;

[0046] Step A: P...

Embodiment 2

[0051] Taking an EMU in Kunming, Yunnan as an example, the COD of septic tank effluent wastewater is 4700mg / L, SS is 1820mg / L, ammonia nitrogen is 1400mg / L, total nitrogen is 1650mg / L, and total phosphorus is 178mg / L. The trains managed by the train will unload sewage at this station, and the amount of sewage discharged is relatively small. The municipal pipe network of the train station is well-arranged and has been negotiated with the urban sewage treatment plant. It can be discharged to the municipal management if it meets the sewage discharge standard of the urban sewage treatment plant. net, followed by subsequent treatment by urban sewage treatment plants.

[0052] According to the processing requirements, the modular configuration of the processing technology only needs to adopt the processing technology described in the present invention, which is a pretreatment system + nitrogen and phosphorus removal system, and the sludge generated in the water treatment process ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com