A method for preparing nickel-hard type I cast iron by using red mud to separate slag and iron efficiently

A technology of slag-iron separation and red mud, applied in the field of metallurgy, can solve the problems of low iron-nickel alloy iron content, various application principles, insufficient iron separation, etc., achieve high iron quality, complete separation, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing nickel-hard cast iron, including the following steps:

[0041](1) After mixing Bayer method, the red soil nickel mine is mixed according to 7: 3 mass ratio, and the mass of 20% coke is added to the mixture, and the mass 3% of the mass is mixed, and the mass is 5%. The concentration was 4% aqueous sodium silicate solution, and then mixed uniform, cold pressure was dried in a drying tank at 60 ° C for 2 h, resulting in a mixture;

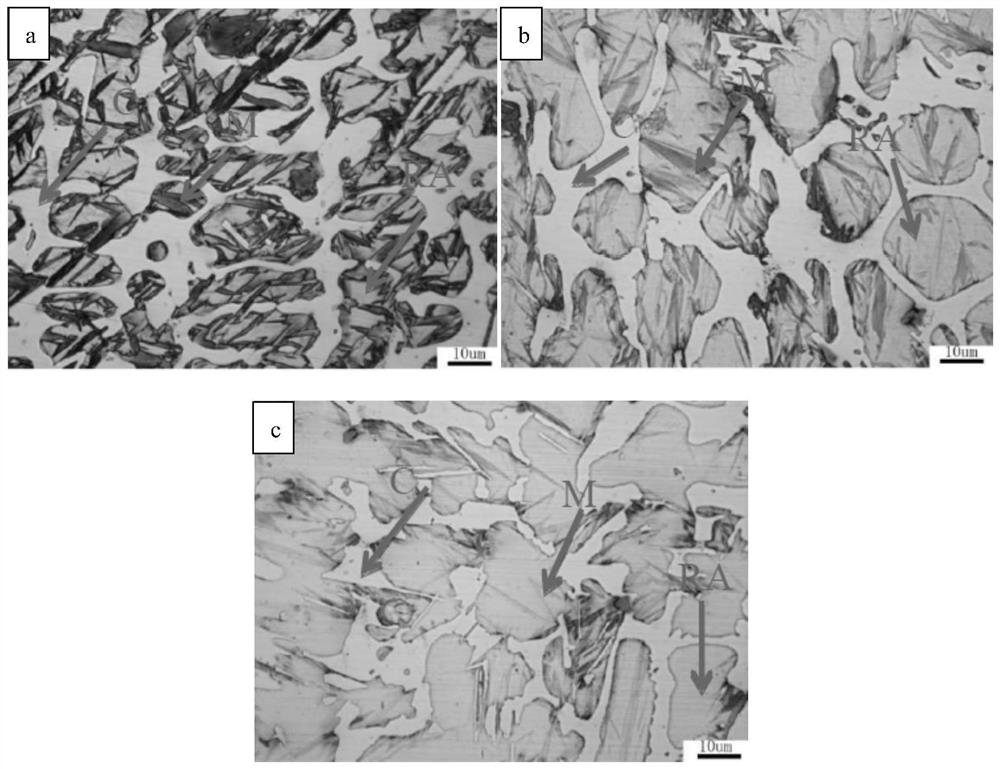

[0042] (2) After preheating the mixture at a temperature of 340 ° C for 3.5 h, it is placed in a medium-frequency induction furnace to heat reduction to obtain a ferric alloy; Image 6 As shown, iron alloy and slag separation thoroughly, resulting in the outer surface of the ferric alloy);

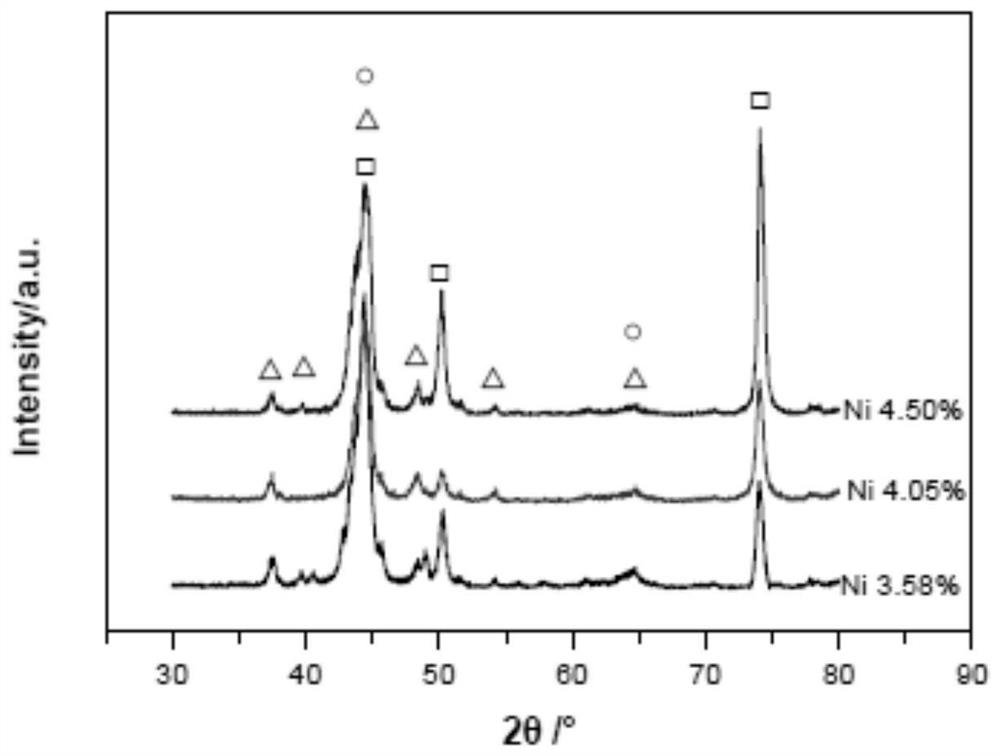

[0043] (3) After the iron alloy is added to the carbon-carbon-proof treatment, the addition of nickel, chrom is prepared into nickel coastal iron; the nickel content is added to a total nickel content of 3.58 wt.%, And the chromium content...

Embodiment 2

[0045] The difference from Example 1 is:

[0046] (3) After the iron alloy is removed, the addition of nickel is added to the addition of nickel, and the chrom is prepared into nickel coarse iron; the nickel content is added to a total nickel content of 4.05 wt.%, And the chromium content is added to a total chromium content of 1.88 wt.%.

Embodiment 3

[0048] The difference from Example 1 is:

[0049] (3) After the iron alloy is removed, the addition of nickel is added to the addition of nickel, and the chromium is prepared into nickel coarse iron; the nickel content is added to a total nickel content of 4.50 wt.%, And the chromium content is added to a total chromium content of 2.21 wt.%.

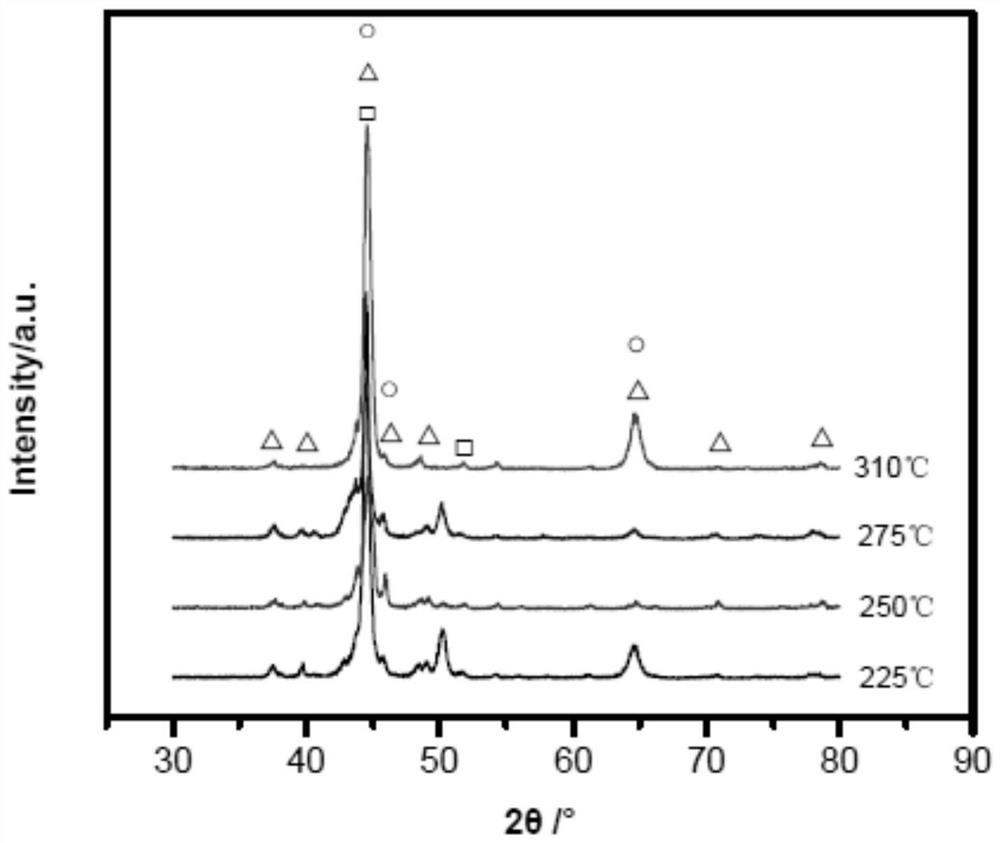

[0050] First, the nickel hard cast iron prepared by Example 1-3 was performed as follows:

[0051] Chemical composition analysis

[0052] Test the chemical composition analysis of cast iron alloy samples using ARL8860 direct reading spectrometer. Before the test, the oxidation of the sample surface was grinded with a grinding wheel, and then the sample was placed on the sample stage. The chemical composition obtained is in Table 2.

[0053] Table 2

[0054]

[0055]

[0056] The iron content of nickel-hard cast iron was 90.283 to 90.719%, and the chemical composition of each group was composed of nickel hard type I cast iron requirements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| L | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com