Calcium borate whisker and preparation method thereof

A calcium borate and whisker technology, which is applied in the field of calcium borate whiskers and its preparation, can solve the problems of high cost, random shape, complicated operation, etc., and achieve the effects of significant impact, significant reaction temperature, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of calcium borate whisker of the present invention, comprises the steps:

[0034] a. Ball milling: Boron source, calcium source and co-solvent are mixed, ball milled for 1-10 minutes, and the ball-milled material is obtained;

[0035] b. Calcination: The ball-milled material is calcined at 800-1000°C for 2-6 hours to obtain the calcined product;

[0036] c. Impregnation: After calcination, the product is cooled, added with water at 70-90°C for impregnation, and then the solid is washed and dried to obtain calcium borate whiskers.

[0037] Through the method of the invention, calcium borate whiskers can be successfully prepared, the operation is simple and the cost is low, and the obtained whiskers have high crystallinity, good thermal stability, high purity and uniform appearance.

[0038] Step a is a ball milling step, in which the boron source, calcium source and co-solvent are mixed and then ball milled. Wherein, the ball milling can adopt co...

Embodiment 1

[0051] A method for preparing calcium borate whiskers, comprising the steps of:

[0052] (1) Ingredients: weigh 1.0153g CaCl 2 , weighed 2.9937g Na 2 B 4 o 7 10H 2 O, take by weighing 5.4301g KCl, mix homogeneously, promptly boron-calcium mol ratio is 3.4:1, and the mol ratio of boron-calcium and potassium chloride is 1:1.8.

[0053] (2) Grinding: transfer the uniformly mixed materials into a vibrating ball mill jar, grind for 2 minutes, and transfer all the powders into a ceramic crucible.

[0054] (3) Calcination: Cover the crucible and place it in a muffle furnace for calcination at 900°C for 4 hours, then cool with the furnace.

[0055] (4) Impregnation: The calcined sample is impregnated at 80°C to remove residual NaCl, KCl and B 2 o 3 .

[0056] (5) Washing: the impregnated sample is washed, filtered, and dried at 105° C. to obtain the calcium borate whisker product with a yield of about 94.8%.

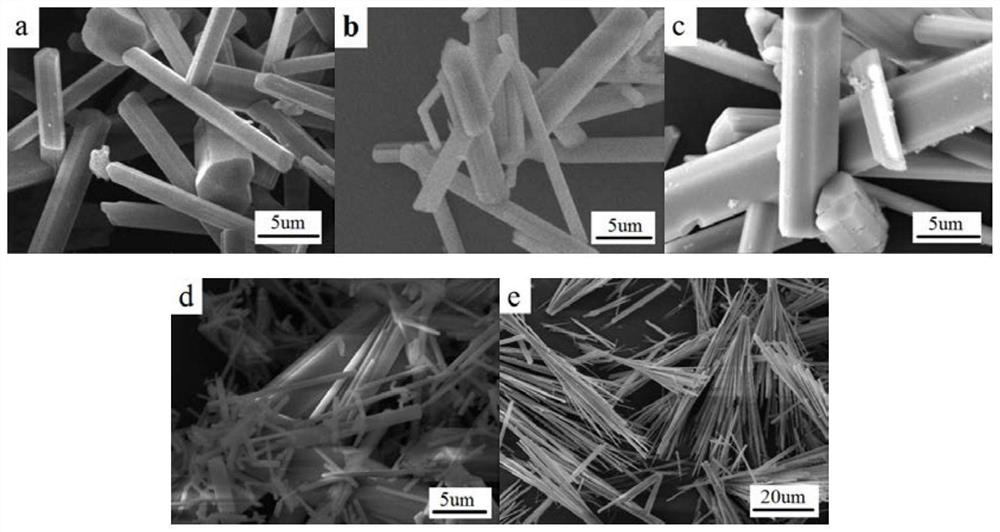

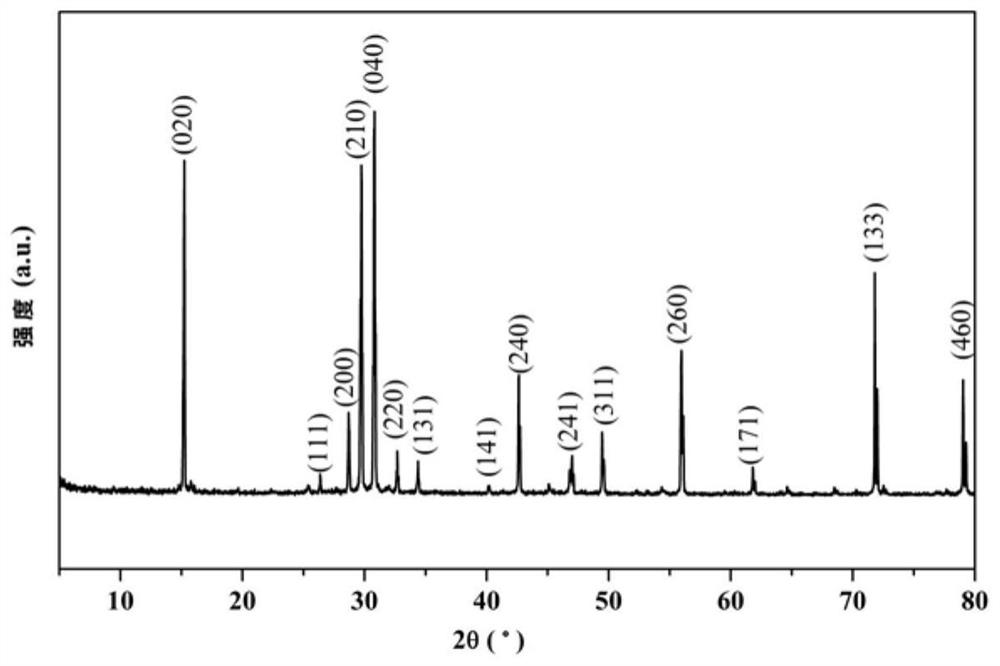

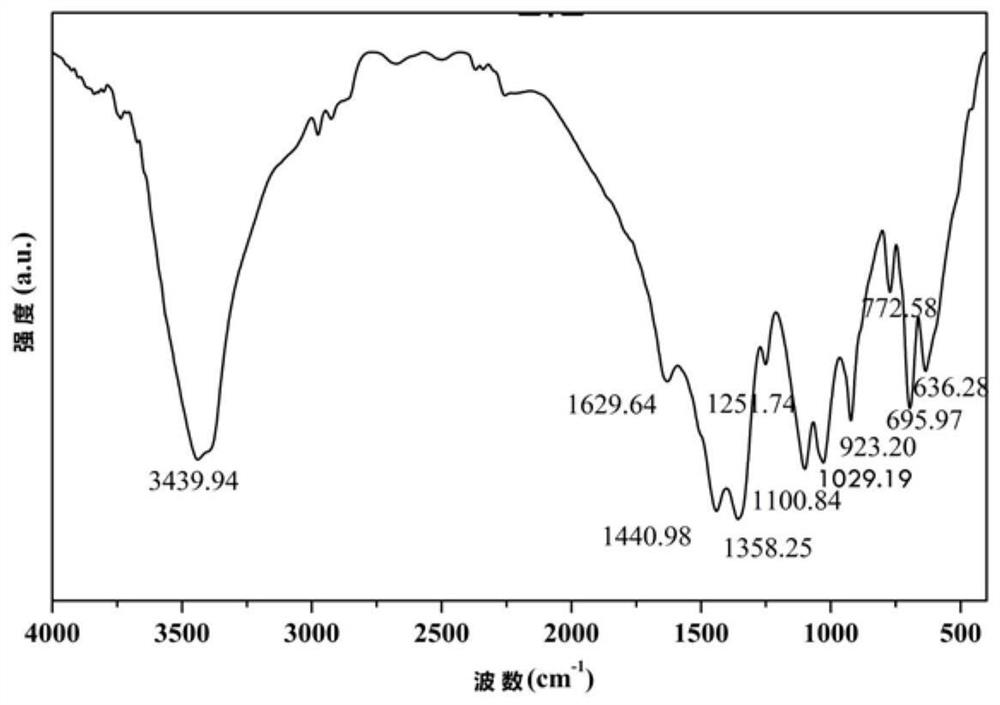

[0057] Gained calcium borate whiskers were characterized, the resu...

Embodiment 2

[0060] A method for preparing calcium borate whiskers, comprising the steps of:

[0061] (1) Ingredients: weigh 1.6794g CaO, weigh 11.4217g Na 2 B 4 o 7 10H 2 O, weigh 11.1632g KCl and mix evenly, that is, the molar ratio of boron to calcium is 4:1, and the molar ratio of boron to calcium to potassium chloride is 1:1.

[0062] (2) Grinding: transfer the uniformly mixed materials into a vibrating ball mill jar, grind for 5 minutes, and transfer all the powders into a ceramic crucible.

[0063] (3) Calcination: Cover the crucible and put it into a muffle furnace for calcination at 950°C for 2 hours, then cool with the furnace.

[0064] (4) Impregnation: The calcined sample is impregnated at 80°C to remove residual NaCl, KCl and B 2 o 3 .

[0065] (5) Washing: the impregnated sample is washed, filtered, and dried at 105°C to obtain calcium borate whiskers with a yield of about 93.1%.

[0066] The SEM spectrum of the calcium borate whiskers is detailed in figure 1 b. Its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com