SNCR and low-temperature SCR coupled flue gas denitration system and use method thereof

An SCR reactor, low temperature technology, applied in the field of SNCR and low temperature SCR coupled flue gas denitrification system, can solve the problems of insufficient layout space, complex system, large workload and investment cost, and achieve the guarantee of flue gas temperature level and system economy. Good, ensure the effect of denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

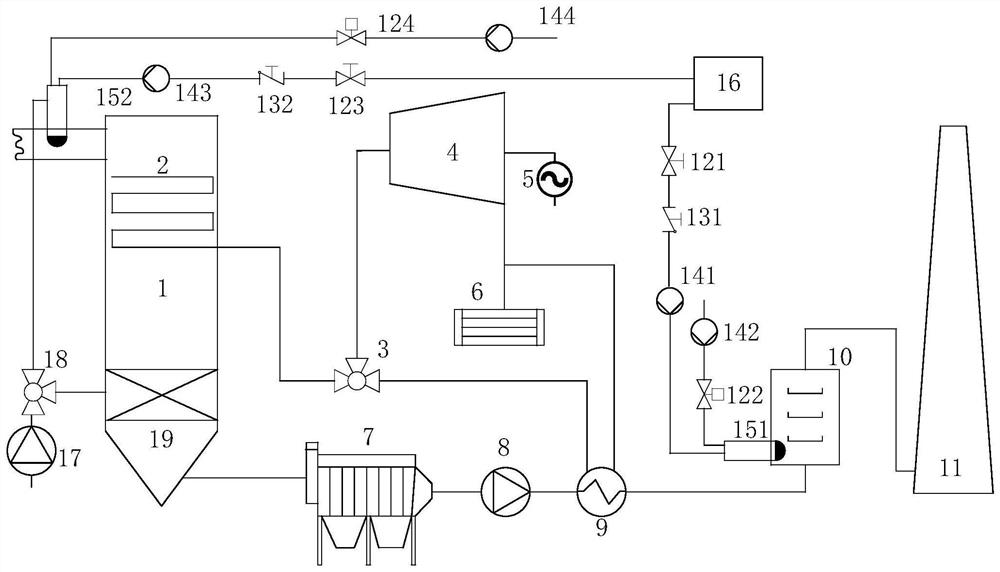

[0024] A SNCR-coupled low-temperature SCR flue gas denitrification system proposed by the present invention and its application method will be described in detail below in conjunction with the accompanying drawings.

[0025] The present invention provides an SNCR coupled low-temperature SCR flue gas denitrification system, wherein the main spray gun 152 is connected to the outlet of the ammonia water tank 16 through the ammonia water pump 143, and a first ammonia water valve 123 and a first ammonia water valve 123 are arranged between the ammonia water tank 16 and the ammonia water pump 143. Ammonia check valve 132; main spray gun 152 air inlet is connected with air compressor 144 air outlets, and compressed air channel is provided with compressed air valve 124; The cold air distribution valve 18 is provided with a cooling air outlet, and the cooling air outlet is used to send the cold air produced by the primary fan to cool the main spray gun 152;

[0026] Further, the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com