Simultaneously high-efficiency silicon release and heavy metal adsorption modified biochar and preparation method

A technology for adsorbing heavy metals and biochar, applied in the field of farmland soil treatment, can solve the problems of silicon deficiency and limited adsorption and fixation capacity of heavy metals, and achieve the effects of efficient adsorption and fixation, realization of resource utilization, and simple and easy-to-operate preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

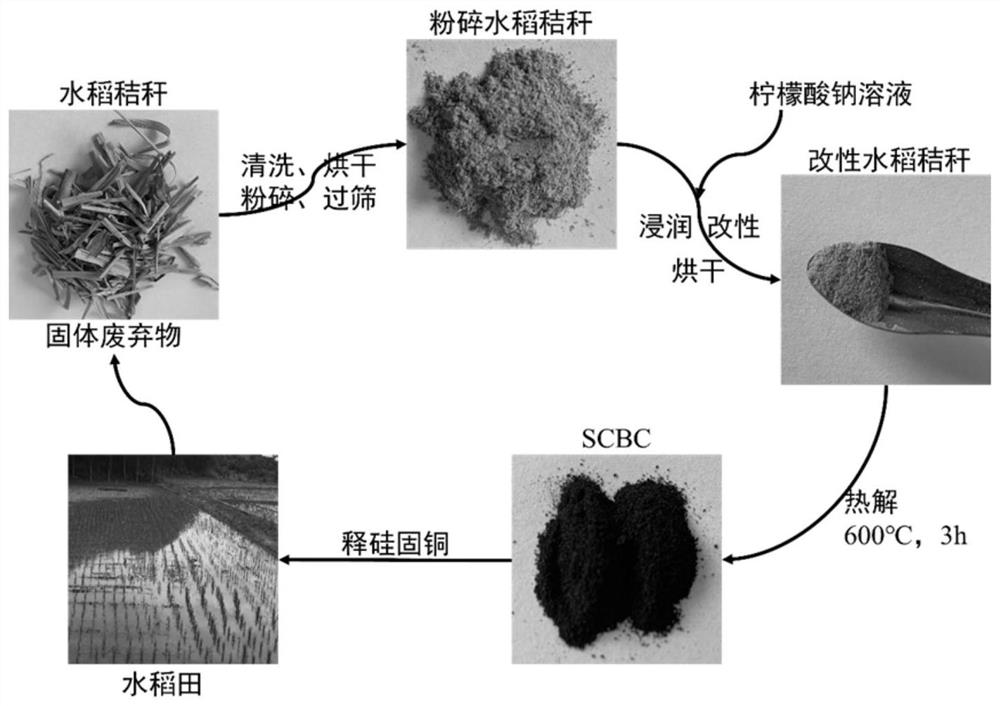

[0035] refer to figure 1 , the embodiment of the present invention provides a method for preparing a sodium citrate modified biochar material that can efficiently release silicon and absorb heavy metals at the same time, comprising the following steps:

[0036] S1, crushing straw;

[0037] S2. Mix the crushed straw with a sodium citrate solution with a concentration of 0.05mol / L-0.5mol / L in a ratio of 1:6-1:10 (m:v), and stir at 20-30°C After uniformity, let it stand to make it fully infiltrated to modify the straw;

[0038] S3, roasting after pulverizing the modified straw;

[0039] S4. Pyrolysis the modified straw obtained in step S3 at 500-600° C. for 2-3 hours in an oxygen-isolated environment, and obtain a sodium citrate modified biochar material after cooling.

[0040] In a preferred embodiment, in step S1, after cleaning the straw, put it in an oven at 70-80°C and dry it until the mass difference between the two weighings does not exceed 0.1%, and then take it out, a...

Embodiment 1

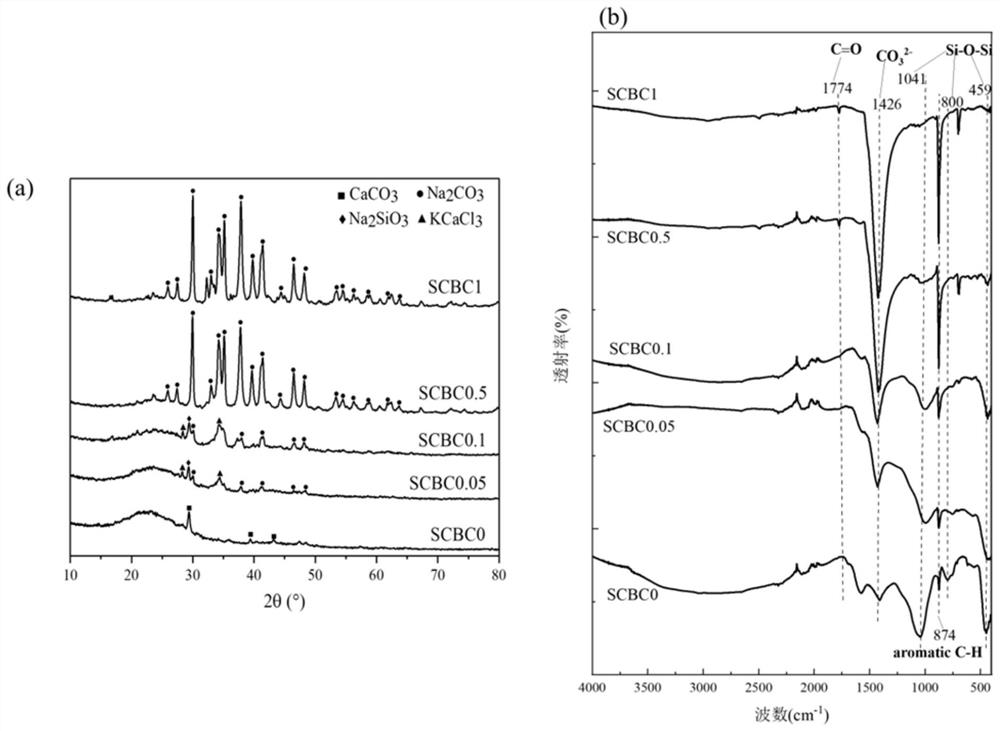

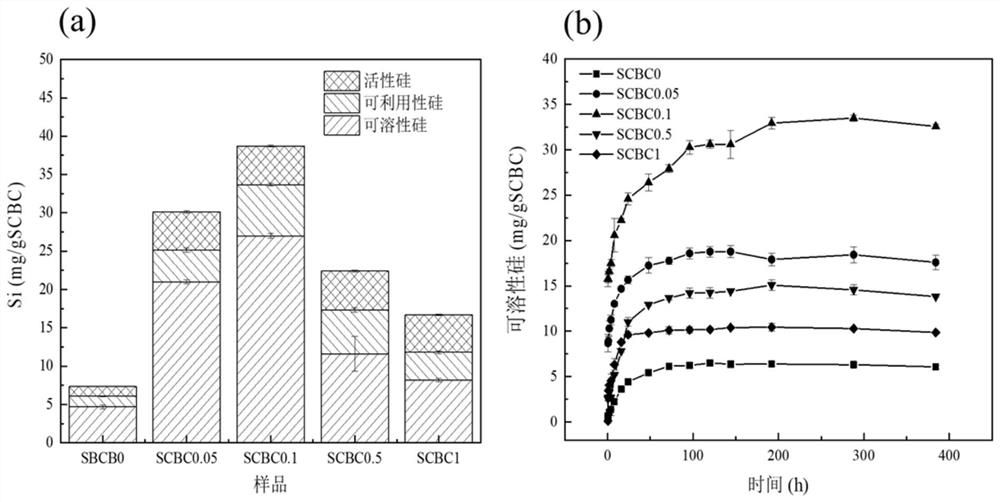

[0071] Collect fresh rice stalks, wash them with distilled water until there are no impurities on the surface, and then dry them in an oven at 75°C until the mass difference between the two weighings does not exceed 0.1%. Take them out. Then the dried stalks were crushed with a pulverizer and passed through a 100-mesh sieve. Then add sodium citrate solutions with concentrations of 0, 0.05, 0.1, 0.5, and 1 mol / L, mix according to the ratio of 1:8 (m:v), stir evenly at 25°C and let it stand for 24 hours to make it fully Infiltration modification. Then put it into an oven at 70-80°C and dry it again until the mass difference between the two weighings does not exceed 0.1%. Finally, it was pyrolyzed at 600° C. for 3 hours in an oxygen-isolated environment, ground after cooling, and passed through a 100-mesh sieve to obtain a sodium citrate modified biochar material. These modified materials were named SCBC0, SCBC0.05, SCBC0.1, SCBC0.5, SCBC1 according to the concentration of sodi...

Embodiment 2

[0074] Collect fresh rice stalks, wash them with distilled water until there are no impurities on the surface, then dry them in an oven at 70-80°C until the mass difference between the two weighings does not exceed 0.1%, and take them out. The dried straw is then pulverized and sieved with a pulverizer. Then add sodium citrate solutions with concentrations of 0, 0.05, 0.1, 0.5, 1mol / L, mix according to the ratio of 1:8 (m:v), stir evenly under the condition of 20-30°C and let it stand for 20-30°C. 24h to fully infiltrate and modify. Then put it into an oven at 70-80°C and dry it again until the mass difference between the two weighings does not exceed 0.1%. Finally, it is pyrolyzed at 600° C. for 2 to 3 hours in an oxygen-isolated environment, ground after cooling, and passed through a 100-mesh sieve to obtain a sodium citrate modified biochar material. These modified materials were named SCBC0, SCBC0.05, SCBC0.1, SCBC0.5, SCBC1 according to the concentration of sodium citra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com