A method for preparing antibacterial and antiviral coatings using sodium dichloroisocyanurate process wastewater

A sodium dichloroisocyanurate and anti-virus technology is applied in the fields of comprehensive utilization of resources and paint processing, which can solve problems such as easy blockage of equipment and pipelines, difficulty in handling, and corrosion of equipment, so as to solve emission problems, realize comprehensive utilization, and improve Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

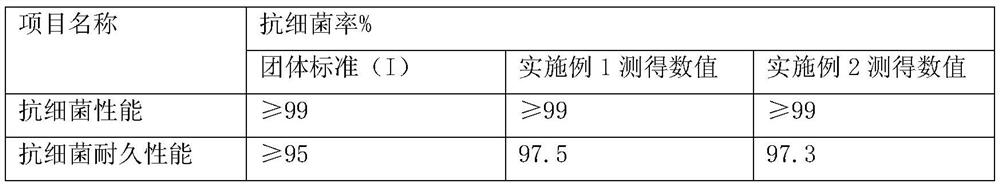

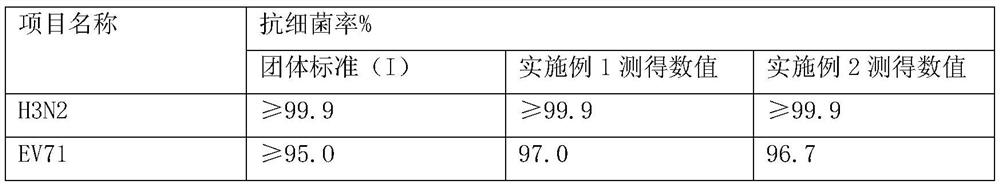

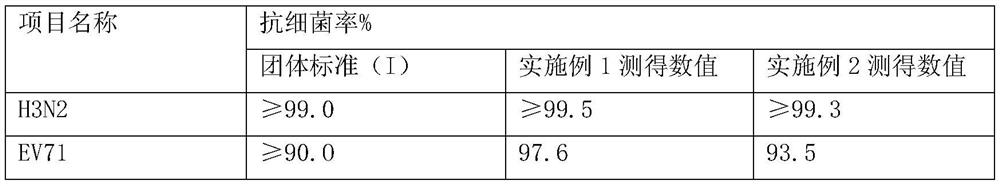

Embodiment 1

[0025] A kind of method adopting sodium dichloroisocyanurate process waste water to prepare antibacterial and antiviral coating comprises the steps:

[0026] 1) Preparation of antibacterial and antiviral component A:

[0027] a, process waste water 1395kg (available chlorine content 1.52%, calcium chloride content 10.7%, temperature 32.5 ℃) in the chlorination process of detoxifying agent sodium dichloroisocyanurate production process, add it in the neutralization kettle, under stirring Add 10.8kg of ultra-fine calcium hydroxide with a particle size of 1250 mesh for neutralization reaction. After stirring for 30 minutes, the pH value is 7.02. Naturally cool down to 20°C under stirring, then let it settle for 5.5 hours, and drain the supernatant to waste water In the treatment process, the suspension and sedimentation concentrated solution in the lower layer is collected for use. The concentrated solution has a quality of 67.2kg, an available chlorine content of 30.6%, a calciu...

Embodiment 2

[0031] A kind of method adopting sodium dichloroisocyanurate process waste water to prepare antibacterial and antiviral coating comprises the steps:

[0032] 1) Preparation of antibacterial and antiviral component A:

[0033] a, process waste water 1420kg (available chlorine content 1.45%, calcium chloride content 10.4%, temperature 31.0 ℃) in the chlorination process of detoxifying agent sodium dichloroisocyanurate production process, add it in the neutralization kettle, under stirring Add 10.5 kg of superfine calcium hydroxide with a particle size of 1250 mesh to carry out neutralization reaction. After stirring for 30 minutes, the pH value is 6.98. Naturally cool down to 20°C under stirring, then let it settle for 6.0 hours, and drain the supernatant to waste water In the treatment process, the suspension and sedimentation concentrated solution in the lower layer is collected for use. The concentrated solution has a quality of 66.4kg, an available chlorine content of 30.7%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com