Green and intelligent preparation method of high-purity diquafosol tetrasodium

A high-purity technology for tetrasodium phosphazene, which is applied in the field of green and intelligent preparation of high-purity diquafosor tetrasodium, can solve the problems of complicated process, high difficulty in operation, large loss and the like, and achieves simple and fast operation and complicated operation. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a method for preparing green and intelligent diquafosol tetrasodium, comprising the following steps:

[0048] 1) In the presence of the first condensing agent, condense disodium uridine monophosphate and disodium hydrogen phosphate dodecahydrate at 55°C to synthesize disodium uridine diphosphate;

[0049] 2) In the presence of the second condensing agent, uridine diphosphate disodium, magnesium chloride hydrate, and 4-dimethylaminopyridine are condensed again at 55° C. to generate diquafosol tetrasodium.

[0050] In the present invention, under the condition that the first condensing agent exists, uridine monophosphate disodium and dodecahydrate disodium hydrogen phosphate undergo condensation reaction at 55 DEG C to synthesize uridine diphosphate disodium.

[0051] In the present invention, the first condensing agent is preferably dissolved in an auxiliary agent; the auxiliary agent is preferably a water-acetonitrile mixed solution; the volume rati...

Embodiment 1

[0064] The preparation method of embodiment 1 diquafosol tetrasodium (batch production 50g)

[0065] 1. The preparation method of uridine diphosphate disodium (UDP 2Na)

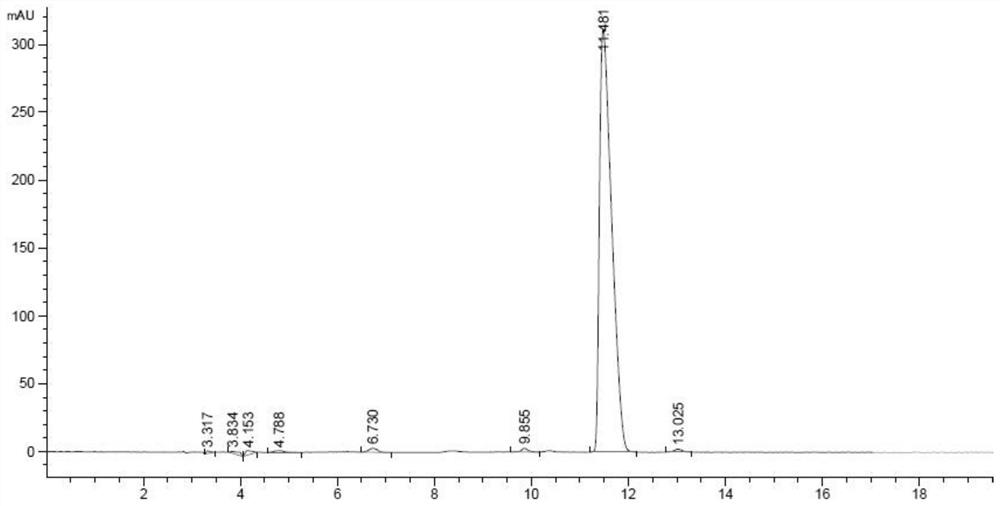

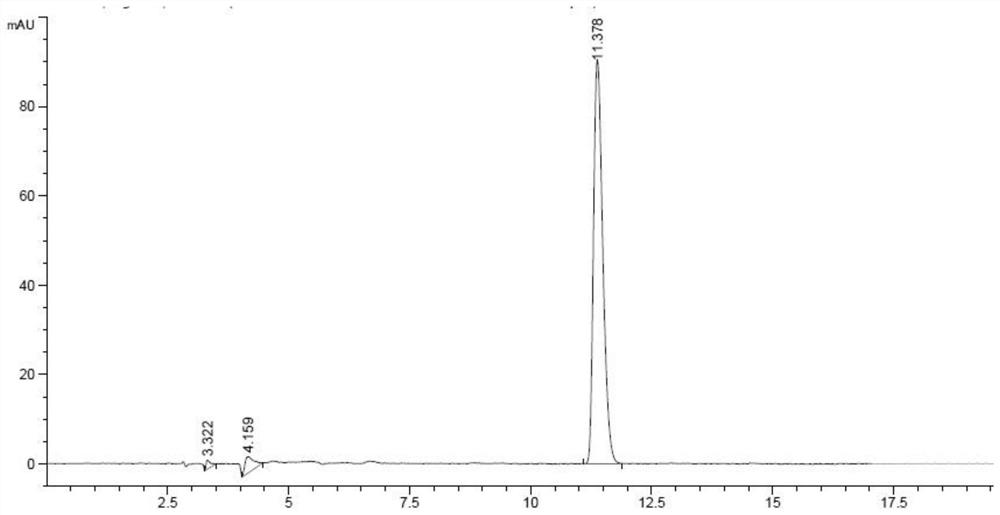

[0066] Add 3 liters of 50% acetonitrile aqueous solution and 0.57 kg of 1,3-dimethyl-2-chloroimidazoline hexafluorophosphate (DMP) to the reaction flask that has been placed in cold water at 0°C, stir to dissolve, and control the temperature At 0°C, add 0.285kg imidazole (IM) and stir to dissolve, heat up to 40°C, stir and react for 10 minutes, add 0.25kg UMP·2Na (see the HPLC spectrum of uridine URD Figure 4 ; The HPLC collection of illustrative plates of uridine monophosphate disodium (UMP 2Na) reference substance sees Figure 5 ), stirred and reacted at 40°C for 30 minutes, then added 0.425kg of disodium hydrogen phosphate 12 hydrate, heated to 55°C, continued to stir and react for 4 hours, filtered, the filtrate was rotary evaporated to recover acetonitrile for reuse, and added pure water to the remaini...

Embodiment 2

[0070] The preparation of embodiment 2 diquafosol tetrasodium (batch production 500g)

[0071] 1. Synthesis of uridine diphosphate disodium (UDP·2Na)

[0072] Add 30 liters of 50% acetonitrile aqueous solution and 5.7 kg of 1,3-dimethyl-2-chloroimidazoline hexafluorophosphate (DMP) in sequence to the reactor placed in cold water at 0°C, stir to dissolve, and control the temperature At 0°C, add 2.85kg of imidazole (IM) and stir to dissolve, raise the temperature to 40°C, stir for 10 minutes, add 2.5kg of UMP·2Na, stir for 30 minutes at 40°C, then add 4.25kg of disodium hydrogen phosphate dodecahydrate , heat up to 60°C, continue to stir and react for 4 hours, filter, and recycle the filtrate to recover acetonitrile for use, add pure water to dilute the remaining liquid to 10g UMP / L liquid, pass through the HZ-201 resin column, first use 13BV 0.06N sodium chloride and Wash with a mixed solution of hydrochloric acid with a pH value of 2, then elute with a mixture of 11BV 0.12N s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com