Fuel cell anode catalyst and preparation method and application thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of indeterminate Ru-P composition of the catalyst, long reaction time, and insufficient activity and stability of the Ru-P catalyst. Improvement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The invention provides a method for preparing a fuel cell anode catalyst, comprising the following steps:

[0072] S1. Add the transition metal source and trioctylphosphine oxide into the reaction vessel according to a predetermined ratio, mix them, stir and heat to a heating temperature of 90-150°C under vacuum conditions, and keep the heating temperature for the first reaction for 5-60 minutes;

[0073] S2. After the first reaction described in step S1 is completed, the entire reaction system is filled with inert gas, heated to a reaction temperature of 180-400°C, and a predetermined amount of phosphorus source is added, and the second reaction is carried out at the reaction temperature for 0.1-400°C. 6h;

[0074] S3, after the second reaction described in step S2 is completed, cooling, washing and vacuum drying are performed to obtain a reaction product, and then the reaction product is subjected to a loading reaction with a carbon carrier to obtain a predetermined l...

Embodiment 1

[0108] A preparation method of fuel cell anode catalyst:

[0109] S1, 0.1mmol ruthenium acetylacetonate (Ru(acac) 3 ) and 1 g of trioctylphosphine oxide (TOPO) were added into a 50 mL reaction vessel, heated to 120° C. under vacuum with electromagnetic stirring, and kept for 30 min.

[0110] S2, and then fill the whole system with N 2 , heated to a reaction temperature of 320° C., injected 0.5 mL of tri-n-octylphosphine (TOP), and maintained the reaction temperature for 2 h.

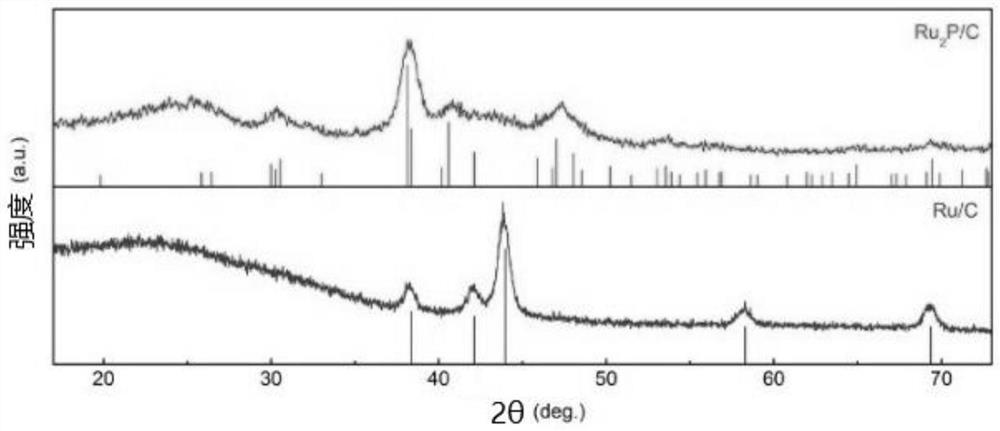

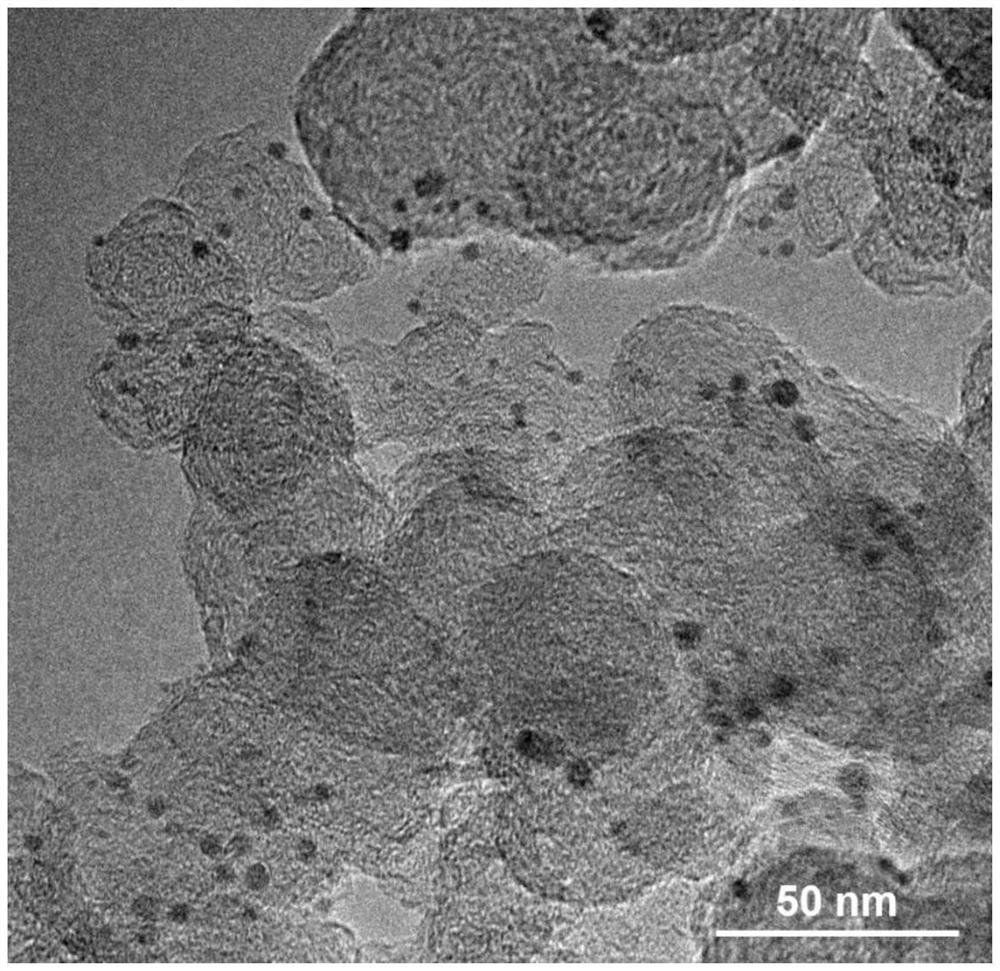

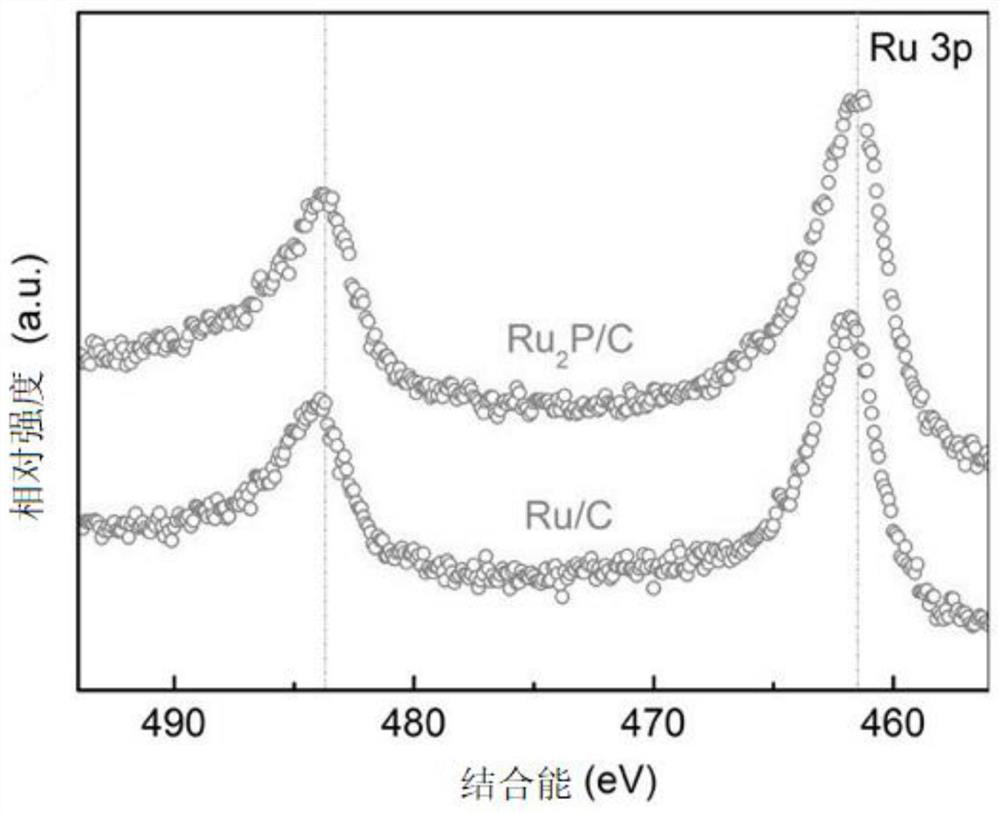

[0111] S3, the reaction is completed, cooled to room temperature, the prepared product is centrifugally washed with ethanol and n-hexane, and then dried under vacuum conditions to prepare Ru-P nanoparticles. Take 5 mg of Ru-P nanoparticles, and add 20 mg of XC-72 carbon carrier into 20 mL of n-hexane and mix evenly, 2 Stir overnight at room temperature under an atmosphere, and dry by centrifugation. The product was then heated at 600°C in 5% H 2 / 95%N 2 Calcined under atmosphere to obtain the final...

Embodiment 2

[0125] S1. Add 0.1 mmol of palladium acetylacetonate and 1 g of trioctylphosphine oxide (TOPO) into a 50 mL reaction vessel, heat to 120° C. under vacuum with electromagnetic stirring, and keep for 30 min.

[0126] S2, and then fill the whole system with N 2 , heated to a reaction temperature of 320° C., injected 0.5 mL of tri-n-octylphosphine (TOP), and maintained the reaction temperature for 2 h.

[0127]S3, the reaction is completed, cooled to room temperature, the prepared product is centrifugally washed with ethanol and n-hexane, and then dried under vacuum conditions to prepare Pd 3 P nanoparticles. Take Pd 3 5 mg of P nanoparticles, and 20 mg of XC-72 carbon carrier were added to 20 mL of n-hexane and mixed evenly, and the 2 Stir overnight at room temperature under atmosphere, and dry by centrifugation to obtain the final 20% loaded catalyst Pd 3 P / C, for HOR test of rotating disk electrode system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com