Preparation method of miniature solid silicon needle

A solid, miniature technology, applied in micro-needles, patterned surface photoengraving process, needles, etc., can solve the problems of increasing the risk of disease infection, skin damage, bleeding, etc., to speed up the internal etching reaction, and the needle body diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

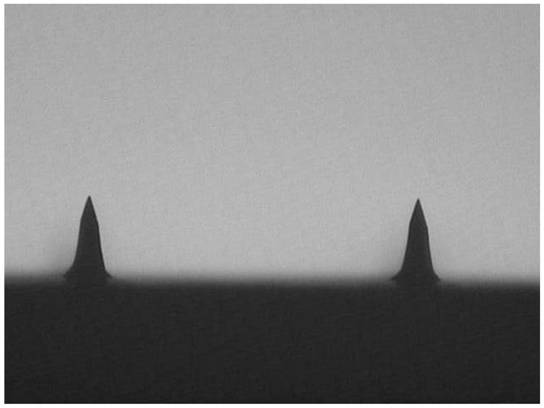

Image

Examples

Embodiment

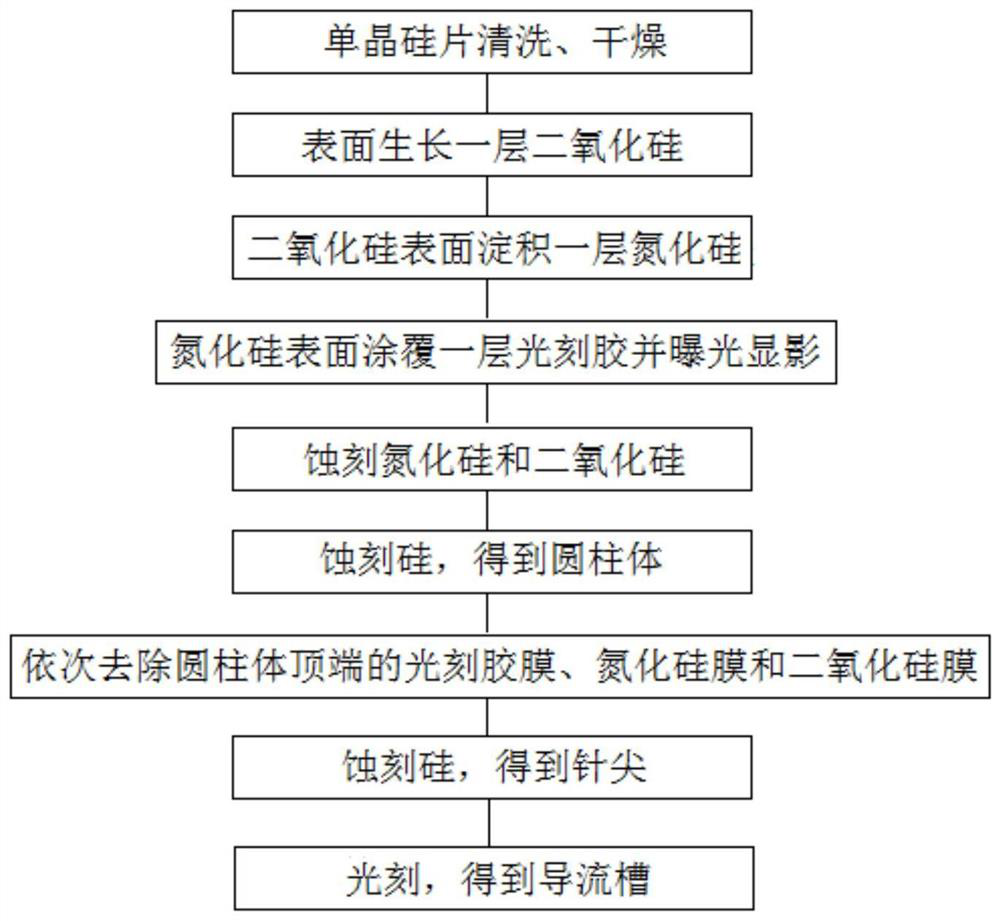

[0037] Such as image 3 Shown, the preparation method of miniature solid silicon needle in the present embodiment, comprises the following steps:

[0038] 1) Select (100) crystal planes, single- or double-sided polished single-crystal silicon wafers, the selected single-crystal silicon wafers are N-type, and the resistivity is 5Ω cm (in actual operation, the resistivity range is selected to be 1 -10Ω·cm, the thickness can be 700±10μm). After cleaning with standard cleaning solution RCA1 (the molar ratio of water:ammonia:hydrogen peroxide is 5:1:1) and RCA2 (the molar ratio of water:hydrochloric acid:hydrogen peroxide is 5:1:1), it is cleaned with deionized water and dehydrated dry.

[0039] 2) A single crystal silicon wafer is oxidized to grow a layer of silicon dioxide in the order of wet oxygen-dry oxygen. The oxidation temperature is controlled below 1100 ° C, and the time of wet oxygen and dry oxygen is 5 hours.

[0040] 3) Deposit a layer of silicon nitride with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com