Anti-corrosion system, preparation method and application thereof and anti-corrosion coating

An anti-corrosion coating and anti-corrosion technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of passive barriers, achieve the effects of slowing down penetration, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Among them, the preparation method of the fluorine-containing piezoelectric resin coating specifically includes: dissolving the fluorine-containing piezoelectric resin in a solvent, and mixing to obtain a fluorine-containing piezoelectric resin precursor solution; and then coating the fluorine-containing piezoelectric resin precursor solution On the surface of the protected substrate, a fluorine-containing piezoelectric resin coating is formed after drying. (The fluorine-containing piezoelectric resin precursor solution here can be regarded as the aforementioned anti-corrosion coating)

[0075] Wherein, the drying may be carried out at room temperature, or may be carried out in a blast drying oven at a temperature of 25-60° C., and the drying time is 2-24 hours for removing the solvent.

[0076] Among them, solvents include but not limited to dichloromethane, chloroform, n-hexane, butyrolactone, diethyl ether, ethyl acetate, tetrahydrofuran, dimethyl sulfoxide, N,N-dime...

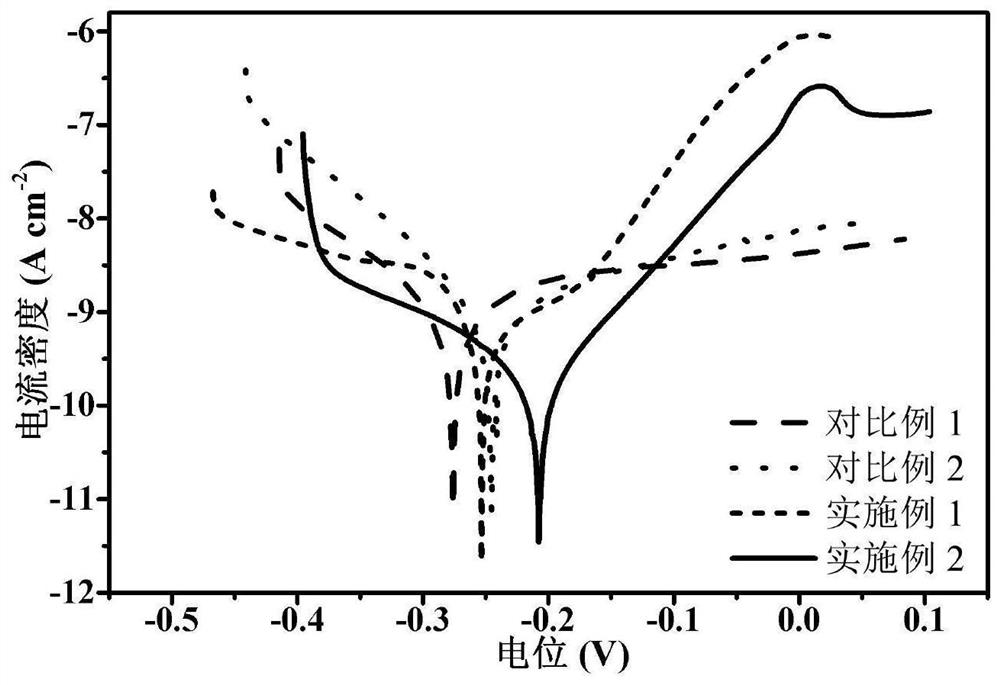

Embodiment 1

[0098] Calculated by mass, 10 parts of polyvinylidene fluoride piezoelectric resin was weighed, and then 90 parts of dimethyl sulfoxide solvent was added, and stirred for 2 hours under heating at 60° C. until uniformly mixed. Then stop heating, add 0.5 parts of silica nucleating agent, and continue stirring for 1 h to obtain A precursor solution.

[0099] Take the Q235 carbon steel substrate, and firstly polish it step by step with 200 mesh, 400 mesh, 800 mesh, 1000 mesh, and 1500 mesh sandpaper, then perform ultrasonic cleaning in ethanol and acetone for 30 minutes, and blow dry the surface of the substrate with nitrogen.

[0100] The prepared A precursor solution was evenly coated on the metal surface by brushing, and then placed in a blast drying oven at 50°C for 2 hours to remove the solvent, and the A coating was formed, and the measured film thickness was 7.01 μm.

[0101] Calculated by mass, weigh 50 parts of bisphenol A diglycidyl ether, 20 parts of polyetheramine D230...

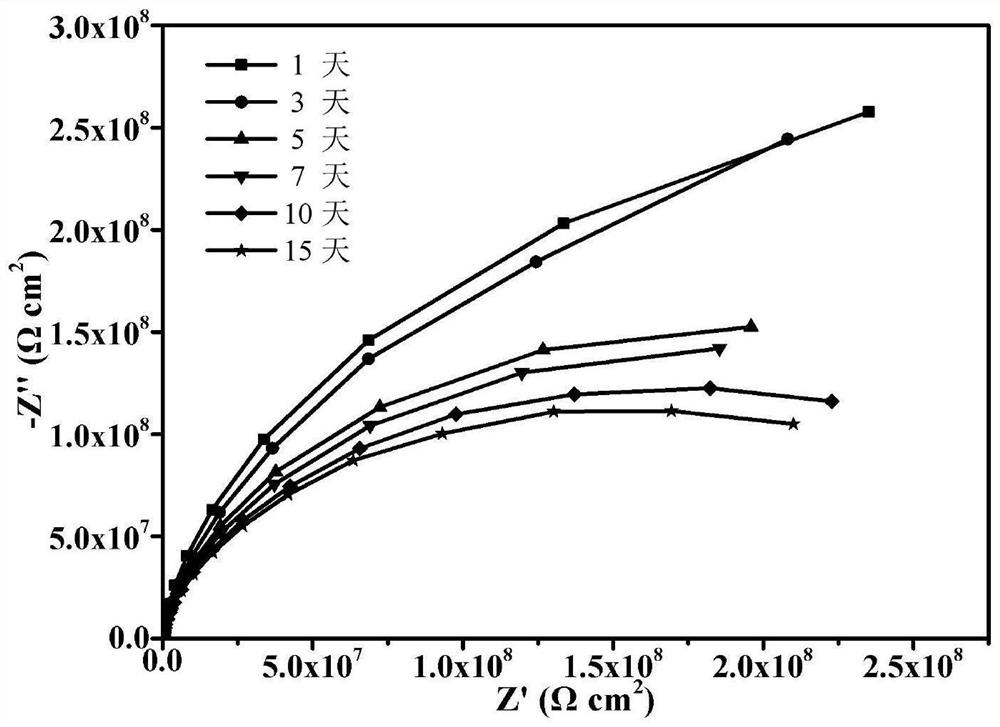

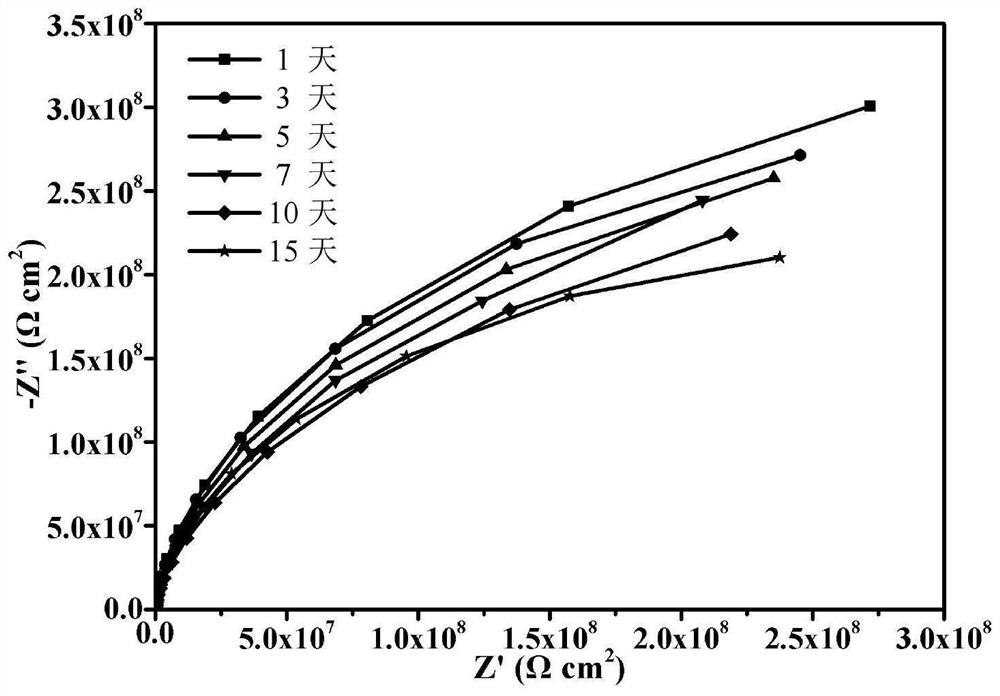

Embodiment 2

[0106] The anticorrosion system and preparation method thereof of the present embodiment are the same as those of Example 1, but the simulated test method is different, and the difference is that the sample is fixed in a container full of 3.5wt% sodium chloride aqueous solution, and the container is placed in a reciprocating Repeated vibrations on a type oscillator to simulate pressure effects such as waves beating on metal substrates in a real ocean environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap