Composite durable antistatic non-asphalt-based self-adhesive gas isolation plate and preparation method thereof

A non-asphalt-based, anti-static technology that can be used in adhesives, adhesive types, adhesive additives, etc., to solve problems such as dimensional changes, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

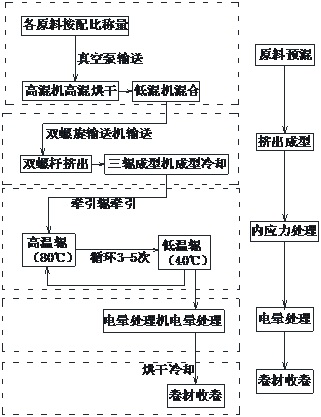

[0128] S1. Preparation of polymer waterproof board:

[0129] ①Raw materials, as shown in Table 1 below:

[0130] Table 1 Example 1 prepares the raw materials that the polymer waterproof board adopts

[0131]

[0132] ②Preparation method:

[0133] A1. Raw material premixing: Inhale all raw materials into the high-mixer through the vacuum pump according to the ratio, and dry them in the high-mixer at a temperature of 53°C, and the mixing time is 3 minutes, and then put them into the low-mixer for 5 minutes. , the raw materials are mixed evenly;

[0134] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after the roll forming machine is thickened and formed;

[0135]A3. Internal stress treatment: The polymer waterproof board form...

Embodiment 2

[0154] S1. Preparation of polymer waterproof board:

[0155] ① Raw materials, as shown in Table 3 below:

[0156] Table 3 embodiment 2 prepares the raw material that polymer waterproof board adopts

[0157]

[0158] ②Preparation method:

[0159] A1. Raw material premixing: Inhale all the raw materials into the high mixer through the vacuum pump according to the ratio, and then dry them in the high mixer at a temperature of 50°C, and the mixing time is 2 minutes, and then put them into the low mixer for 6 minutes. , the raw materials are mixed evenly;

[0160] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after forming by roller forming machine to set thickness (2.0mm);

[0161] A3. Internal stress treatment: The polymer wa...

Embodiment 3

[0180] S1. Preparation of polymer waterproof board:

[0181] ① Raw materials, as shown in Table 5 below:

[0182] Table 5 embodiment 3 prepares the raw material that polymer waterproof board adopts

[0183]

[0184] ②Preparation method:

[0185] A1. Raw material premixing: Inhale all raw materials into the high-mixer through the vacuum pump according to the ratio, and dry them in the high-mixer at a temperature of 55°C, and the mixing time is 4 minutes, and then put them into the low-mixer for 4 minutes. , the raw materials are mixed evenly;

[0186] A2. Extrusion molding: The raw materials mixed uniformly in step A1 are transported into the twin-screw extruder through the twin-screw conveyor, and the polymer waterproof board is extruded through the extrusion temperature of 220°C-240°C, and then passed through three Cool to normal temperature after forming by roller forming machine to set thickness (2.0mm);

[0187] A3. Internal stress treatment: The polymer waterproof ...

PUM

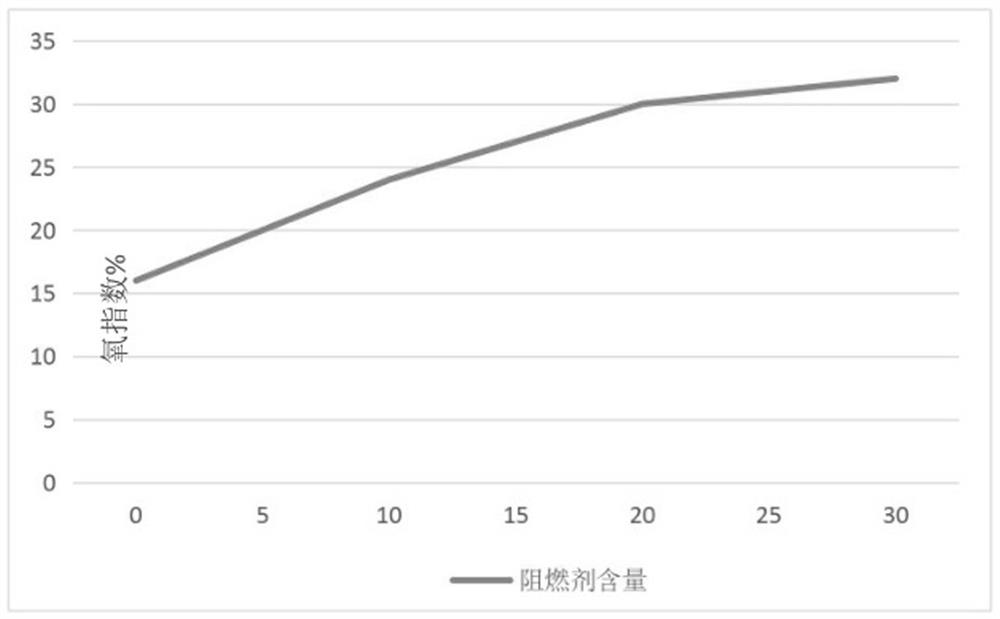

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com