Titanium dioxide aqueous dispersion and method for producing same

A titanium dioxide and dispersion technology, used in cosmetic preparations, cosmetics, pharmaceutical formulations, etc., can solve the problems of reduced visible light transparency shielding, easy agglomeration, etc., and achieve excellent visible light transparency and ultraviolet shielding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

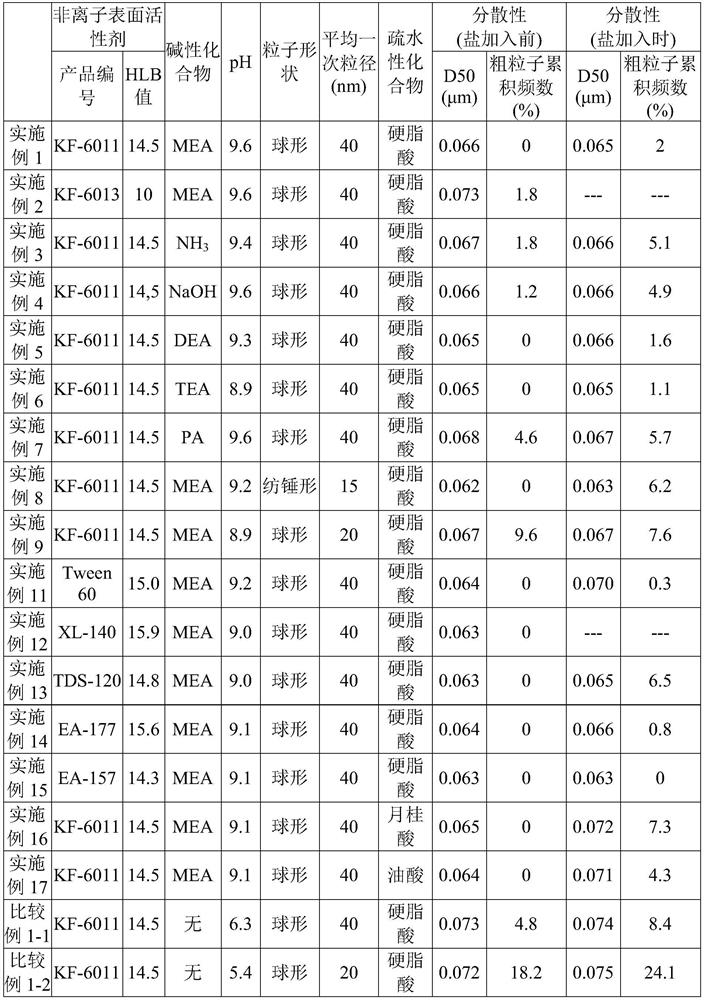

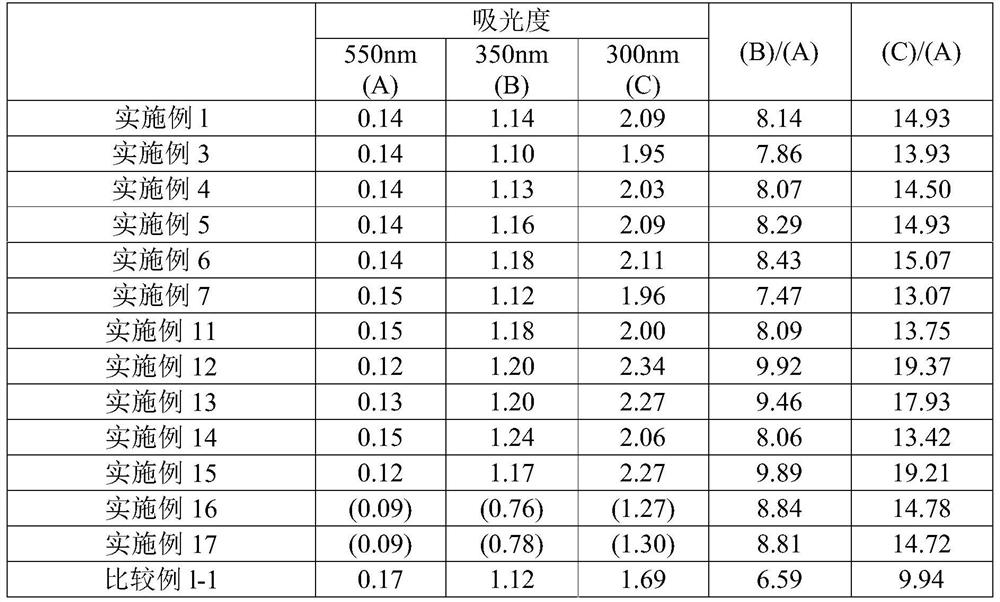

Examples

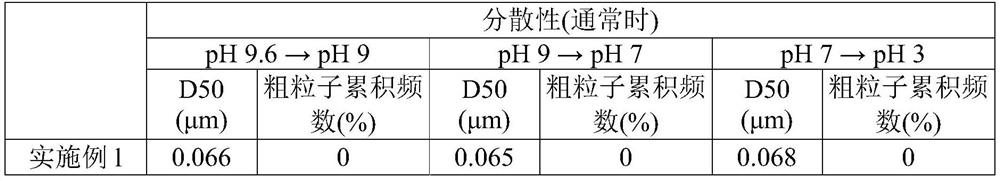

Embodiment 1

[0071] Spherical titanium dioxide ultrafine particles (TTO-55(C), available from Ishihara Sangyo Kaisha, Ltd.) were prepared as hydrophobic compound-coated titanium dioxide particles. Titanium dioxide particles were prepared by the above "calcination method", the crystal form was rutile, the average primary particle diameter measured by electron micrograph method was 40 nm, and the aspect ratio was 1.3.

[0072] Titanium dioxide particles are obtained by using aluminum hydroxide (Al(OH) 3 ) coating the surface of the particles; and further coating with stearic acid. Based on TiO 2 The quality of the aluminum hydroxide coating (amount used for coating treatment) is 3%, and based on TiO 2 The mass of stearic acid (the amount used for coating treatment) was 3%. The details of the production method of titanium dioxide particles are as described in Example 1 of JPH 07-247119 A.

[0073] In addition, the lead content in the titanium dioxide particles was measured by using the fo...

Embodiment 2

[0085] Except that the nonionic surfactant used in Example 1 was changed to PEG-9 polydimethylsiloxane (KF-6013: available from Shin-Etsu Chemical Co., Ltd., HLB value: 10.0), in the same manner as in the implementation The titanium dioxide aqueous dispersion of Example 2 was obtained in the same manner as in Example 1. The pH of the aqueous dispersion was 9.6.

Embodiment 3

[0087] A titanium dioxide aqueous dispersion was obtained in the same manner as in Example 1 except that the basic compound used in Example 1 was changed to a 17% ammonia solution (0.62 parts by mass). The pH of the aqueous dispersion was 9.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com