Shaped Amorphophallus konjac facial mask and preparation method thereof

A facial mask and konjac technology, which is applied in the field of beauty and skin care products, can solve the problems of poor ductility and inability to fit the face, and achieve the effects of strong oxidation, avoiding accelerated aging, good adhesion and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

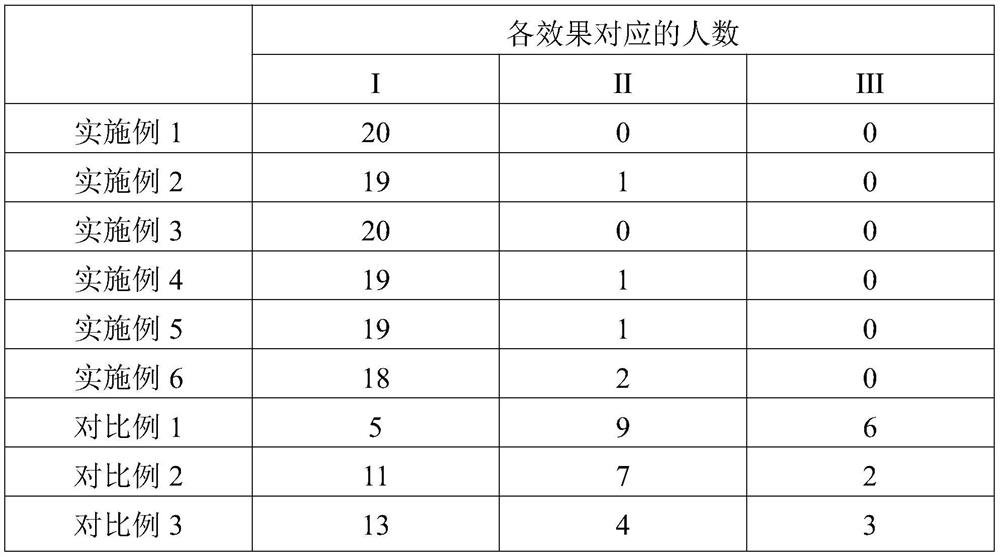

Examples

preparation example Construction

[0019] A method for preparing a shaped konjac facial mask, the preparation method comprising purifying konjac gum, then mixing it with aloe extract, carboxymethyl cellulose and xanthan gum to obtain a mixture, adding glycerin and sodium carbonate to prepare an emulsion, and then aging Forming, dealkalization, sterilization, and finally immersing in a skin care solution to obtain the formed konjac mask.

[0020] As an embodiment, 60-80 parts of konjac gum, 10-20 parts of aloe extract, 15-30 parts of carboxymethyl cellulose, and 5-10 parts of xanthan gum are uniformly mixed to obtain the mixture.

[0021] As an embodiment, the step of purifying konjac gum is: using 30-50wt% ethanol solution to immerse and wash the konjac fine powder several times, and then grind it with a colloid mill, centrifugal filter, and dry to obtain the konjac gum. Describe konjac gum.

[0022] As an embodiment, take 2.5-5 parts of the mixed material, 0.05-5 parts of glycerin, 0.1-0.3 parts of sodium car...

Embodiment approach

[0031] As an embodiment, the preparation method of aloe extract is:

[0032] After pulverizing the dried aloe extract with a pulverizer, put it into a vacuum drying oven at 60°C and bake for 12 hours, pass through an 80-mesh sieve to obtain aloe extract fine powder, take 10 g of the dried aloe extract fine powder, add volume 40mL of ethanol with a ratio of 50%, ultrasonic extraction for 30min, ultrasonic temperature 30°C, heating and evaporating the extract in a water bath, placing it in a drying oven and drying under reduced pressure for 1h to obtain the product.

[0033] (3) Emulsion preparation

[0034] Take 2.5-5 parts of the mixture in step 2 (for example, 2.5 parts, 3 parts, 3.5 parts, 4 parts, 4.5 parts, 5 parts), 0.05-5 parts of glycerin (for example, 0.05 parts, 0.1 parts, 0.2 parts, 0.25 parts, 0.4 parts, 0.5 parts, 0.7 parts, 0.9 parts, 1 part, 1.2 parts, 1.4 parts, 1.6 parts, 1.8 parts, 2.0 parts, 2.2 parts, 2.5 parts, 3 parts, 3.5 parts, 4 parts, 4.5 parts, 5 pa...

Embodiment 1

[0047] (1) Purification

[0048] The konjac fine powder is submerged and washed in 30 wt% ethanol solution, washed 3 times in total, then ground with a colloid mill, centrifugally filtered, and dried to obtain konjac gum;

[0049] (2) Mixing

[0050] Get 60 parts of konjac gums obtained in step 1, mix with 10 parts of aloe extracts, 30 parts of carboxymethylcellulose, and 10 parts of xanthan gum;

[0051] (3) Emulsion preparation

[0052] Take 2.5 parts of the mixed material in step 2, 0.05 part of glycerin, 0.25 part of sodium carbonate, and 75 parts of water and stir to obtain an emulsion;

[0053] (4) Mask forming

[0054] Pour the emulsion into the mask mold, let it stand for 10 hours, then steam it in a steam cabinet at 100°C for 60 minutes to mature, and then freeze it at -20°C~-30°C for 3 days;

[0055] (5) Mold release and alkali removal

[0056] The product in step 4 is thawed and demoulded, washed with water until the pH value is between 6.0-8.0, dehydrated and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com