Hydrocracking catalyst carrier as well as preparation method and application thereof

A catalyst carrier, hydrocracking technology, applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc. Good thermal conductivity, improving acidity and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing a hydrocracking catalyst carrier, the method comprising:

[0049] 1. Put 200.06g of industrial pseudo-boehmite in a muffle furnace, raise the temperature to 600°C at a rate of 4°C / min, and roast for 4 hours to obtain activated alumina.

[0050] 2. Put 120.51g of water glass in a beaker, control the temperature in the beaker to 60°C, add 80g of guiding agent and 220.23g of deionized water, and then add 100g of activated alumina, and mix well to obtain a raw material mixture. Among them, guiding The agent is prepared according to the method provided in Example 1 of CN1785808A.

[0051] 3. Put the raw material mixture into a stainless steel reaction kettle, crystallize at 100°C for 4 hours, then filter, wash and dry to obtain a Y-type zeolite / alumina composite material.

[0052] 4. Weigh 300g Y-type zeolite / alumina composite material, add it to 3000g ammonium nitrate solution (concentration: 0.1mol / L), and perform ion exchan...

Embodiment 2

[0058] This embodiment provides a method for preparing a hydrocracking catalyst carrier, the method comprising:

[0059] 1. Put 500.10g of expanded perlite in a muffle furnace, raise the temperature to 700°C at a rate of 4°C / min, and roast for 4 hours to obtain activated alumina.

[0060] 2. Put 140.84g of water glass in a beaker, control the temperature in the beaker to 60°C, add 130.25g of directing agent and 150g of deionized water, then add 200.7g of activated alumina, stir for 3 hours, and mix well to obtain a raw material mixture , wherein the preparation method of the directing agent is the same as in Example 1.

[0061] 3. Put the raw material mixture into a stainless steel reaction kettle, crystallize at 100°C for 72 hours, then filter, wash and dry to obtain a Y-type zeolite / alumina composite material.

[0062] 4. Weigh 300g Y-type zeolite / alumina composite material, add it to 3000g ammonium chloride solution, perform ion exchange in a 90°C water bath for 1h, suctio...

Embodiment 3

[0068] This embodiment provides a preparation method of a hydrocracking catalyst carrier, which is basically the same as the preparation method provided in Example 1, the difference being that the crystallization time of step 3 is 32 hours, and the obtained hydrocracking catalyst carrier Denoted as sample A-3.

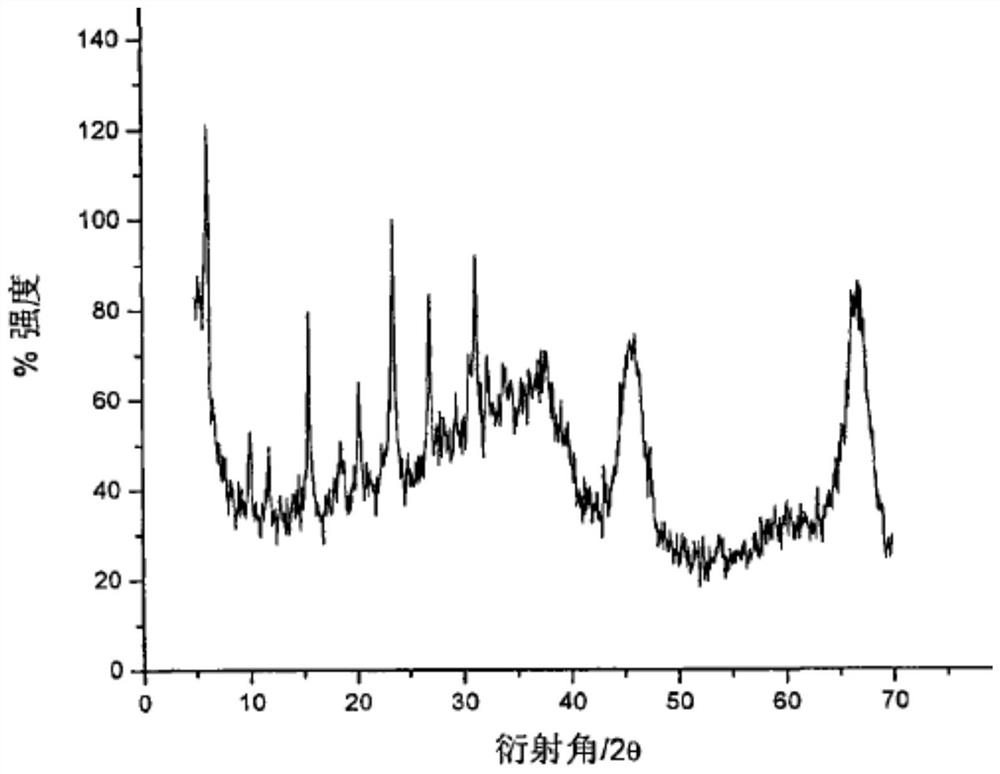

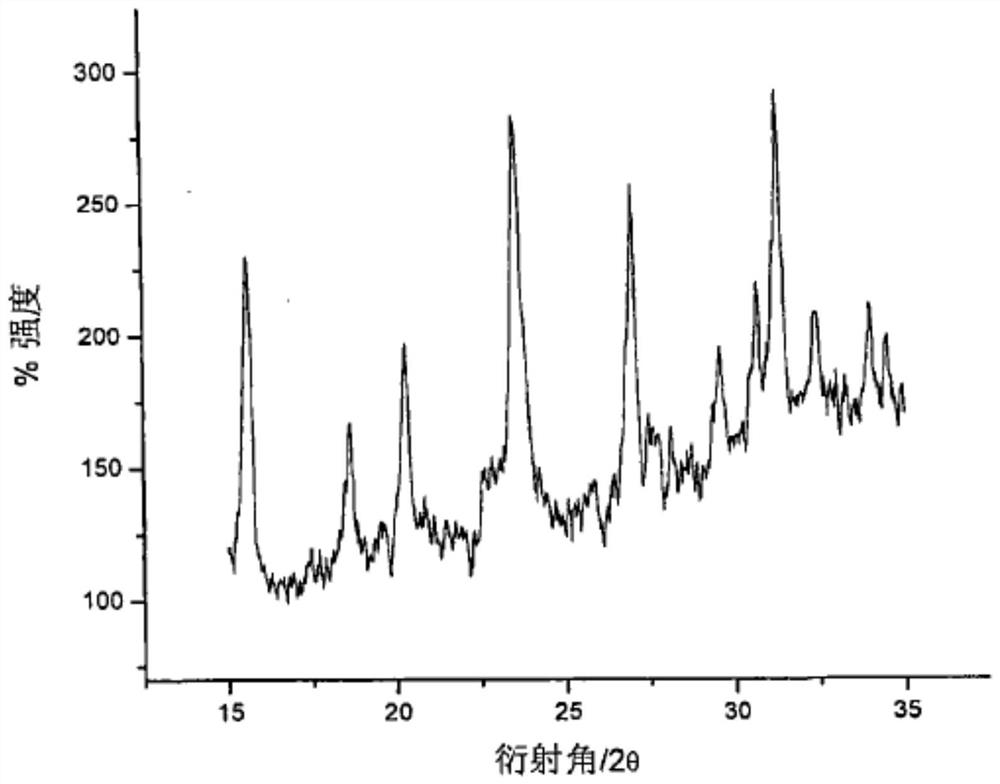

[0069] Sample A-3 was characterized by XRD, and the obtained XRD diffraction spectrum was similar to that obtained in Example 1. Sample A-3 has characteristic peaks of Y-type molecular sieves.

[0070] According to the results of XRD scanning, the measured crystallinity of sample A-3 is 15%, SiO 2 / Al2 o 3 The molar ratio is 8.36; the specific surface area of sample A-3 measured by BET method is 419m 2 / g, the total pore volume is 0.468cm 3 / g, the mesopore volume of sample A-3 measured by BJH method is 0.325cm 3 / g, and the peaks of mesoporous pore size distribution are at 3.8nm and 9.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com