Flexible graphite manufacturing process for hydrogen fuel cell bipolar plate

A flexible graphite and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems affecting the process and graphite plate quality, low raw material utilization rate, and agglomeration of expandable graphite raw materials, so as to achieve good separation effect of gas and materials , High raw material utilization rate, high expansion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The flexible graphite bipolar plate manufacturing process that is used for hydrogen fuel cell, concrete steps are as follows:

[0039] Step (1): Select fine-grained scales with a particle size greater than 150 meshes as the raw material, add concentrated sulfuric acid and hydrogen peroxide in different weight ratios to it for several times, and fully stir and mix sequentially to carry out gradient intercalation reaction.

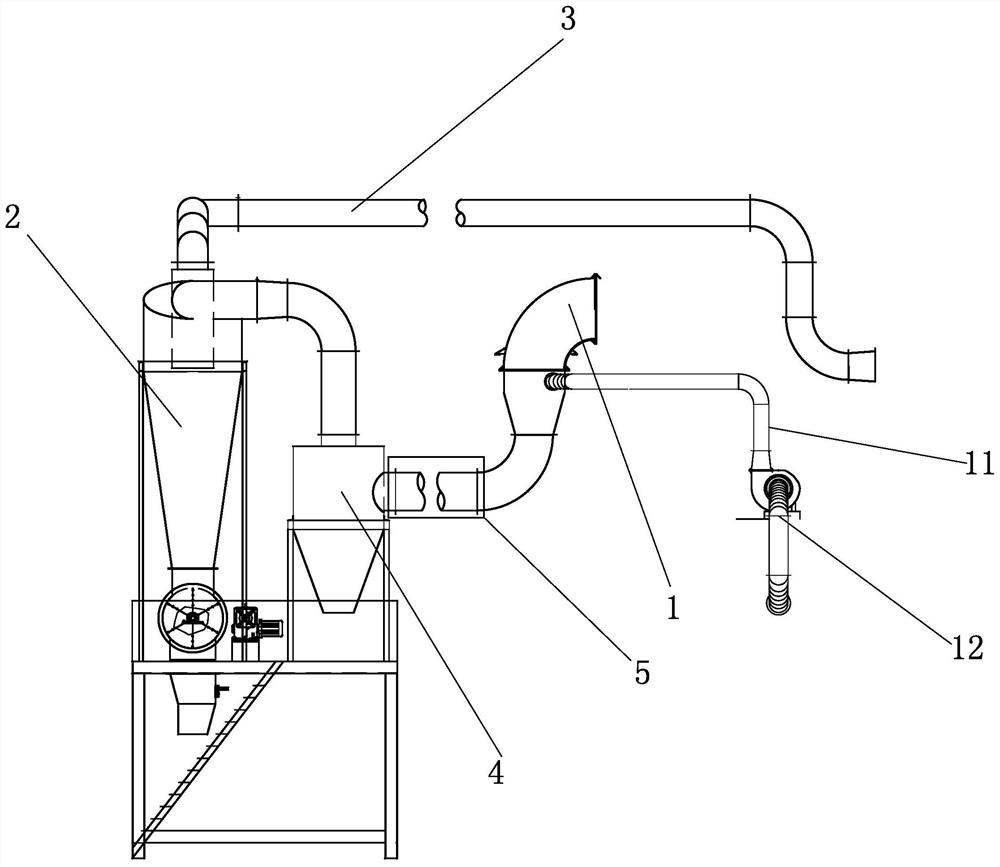

[0040] Step (2): The material obtained in step 1 is mechanically sieved into coarse particles and fine particles, and then the sieved material is air-classified by an air classifier, and the air-classified particle size is greater than 80 mesh and sent to crushing Machine for mechanical crushing, and then air classification again.

[0041] Step (3): Start the feeding fan to send the classified material with a particle size of less than 80 meshes to the puffing furnace for puffing. The puffing temperature is 1000°C. During the puffing pro...

Embodiment 2

[0047] Example 2, the rest of this example refers to Example 1, the difference is that the gradient intercalation reaction in step 1 specifically includes the following steps:

[0048] Step S1: Select 1 part of flake graphite with a particle size of +100 mesh, add 2 parts by weight of 98% concentrated sulfuric acid, mix and stir for 30 minutes, then add 0.1 part by weight of hydrogen peroxide with a concentration of 30%, and continue stirring for 60 minutes; wash with water To neutral, dehydrated, dried to less than 1% moisture;

[0049] Step S2: Take 1 part of the dry material obtained in Step S1, add 3 parts by weight of 98% concentrated sulfuric acid, mix and stir for 30 minutes, then add 0.15 parts by weight of 35% hydrogen peroxide, and continue stirring for 60 minutes; wash with water To neutral, dehydrated and dried until the water content is less than 1%, the test expansion rate is 150ml / g;

Embodiment 3

[0050] Embodiment 3: the remainder of this embodiment is with reference to embodiment 1, and its difference is that the gradient intercalation reaction in step 1 specifically comprises the following steps:

[0051] Step S1: Select 1 part of flake graphite with a particle size of +100 mesh, add 2 parts by weight of 98% concentrated sulfuric acid, mix and stir for 30 minutes, then add 0.1 part by weight of hydrogen peroxide with a concentration of 30%, and continue stirring for 60 minutes; wash with water To neutral, dehydrated, dried to less than 1% moisture;

[0052] Step S2: Take 1 part of the dry material obtained in Step S1, add 3 parts by weight of 98% concentrated sulfuric acid, mix and stir for 30 minutes, then add 0.15 parts by weight of 35% hydrogen peroxide, and continue stirring for 60 minutes; wash with water To neutral, dehydrated and dried until the water content is less than 1%, the test expansion rate is 150ml / g;

[0053] Step S3: Take 1 part of the dry materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Expansion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com