Method for preparing sodium thioglycolate critical saturated aqueous solution from thionocarbamate tail liquid

A technology of sodium thioglycolate and thiourethane, which is applied in the preparation of mercaptans, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of reducing recovery rate, difficult disposal of waste liquid, injury to operators, etc., to avoid production The effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

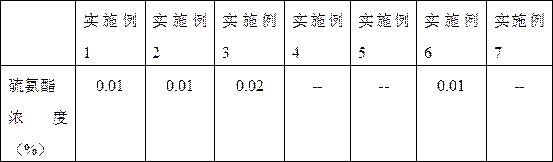

Examples

Embodiment 1

[0037] A kind of method utilizing thiourethane tail liquid to prepare sodium thioglycolate critical saturation liquid, the method may further comprise the steps:

[0038] (1) acidify the tail liquid containing 18wt% sodium thioglycolate for the production of O-alkyl-N-alkylthiocarbamate with dilute hydrochloric acid (31wt%) to a pH of 0.5 to obtain an acidified solution;

[0039] (2) Let the acidification solution stand for 36 hours to form the upper organic layer and the lower acidification layer. First, separate the obvious organic layer, and then use a carbon fiber column to absorb the residual thiourethane and other organic substances in the acidification solution, and completely separate the organic solvent (separation Suspended thiourethane and other organic matter);

[0040] (3) Extract the acidified solution with ethyl acetate 4 times (the volume ratio of the extractant to the acidified solution is 1:3), and after extraction, an extract containing 27.8% of thioglycolic...

Embodiment 2

[0045](1) The tail liquid of O-alkyl-N-alkylthiocarbamate containing 17.6wt% sodium thioglycolate was acidified with dilute hydrochloric acid (31wt%) to a pH of 0.4 to obtain an acidified solution;

[0046] (2) Let the acidification solution stand for 28 hours to form the upper organic layer and the lower acidification layer. First, separate the obvious organic layer, and then filter with a coalescing filter to remove residual thiourethane and other organic substances in the acidification solution, and completely separate the organic layer. Solvents (separation of suspended thiourethane and other organics);

[0047] (3) Extract the acidified solution with 1,2-dichloroethane for 5 times (the volume ratio of extractant to acidified solution is 1:4), and obtain an extract containing 28.9% thioglycolic acid after extraction;

[0048] (4) Add 34wt% tap water to the extract, add 26wt% liquid caustic soda (50% NaOH) under a vacuum of −0.1~−0.98MPa, and use the heat of reaction to rec...

Embodiment 3

[0052] (1) The tail liquid of O-alkyl-N-alkylthiocarbamate containing 18.8wt% sodium thioglycolate was acidified with dilute hydrochloric acid (31wt%) until the pH was 1 to obtain an acidified solution;

[0053] (2) Let the acidification solution stand for 51 hours to form the upper organic layer and the lower acidification layer. First, separate the obvious organic layer, and then filter with ultrafiltration ceramic membrane to remove residual thiourethane and other organic substances in the acidification solution, and separate them thoroughly Organic solvents (separation of suspended thiourethane and other organic matter);

[0054] (3) Extract the acidified solution with 1,2-dichloroethane for 5 times (the volume ratio of extractant to acidified solution is 1:2), and obtain an extract containing 32.0% thioglycolic acid after extraction;

[0055] (4) Add 39wt% tap water to the extract, add 28wt% liquid caustic soda (50% NaOH) under a vacuum of −0.2~−0.8 MPa, and use the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com