Production process of alloy tool steel wire rod with full bainite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

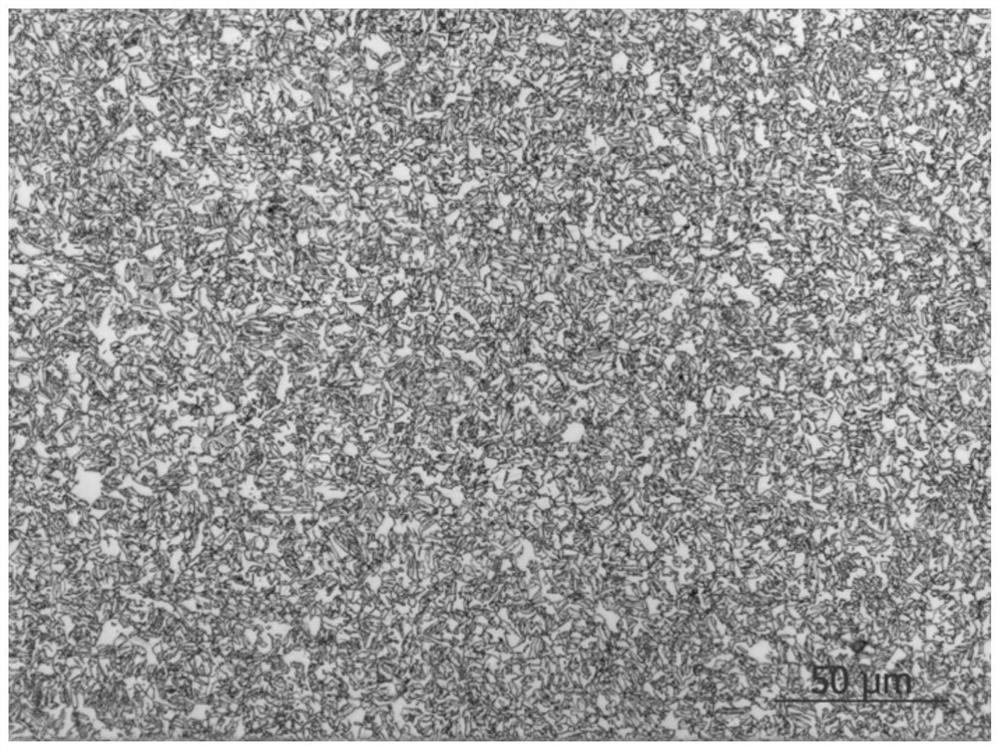

Embodiment 1

[0026] 1. Blank opening

[0027] The composition of the continuous casting slab is calculated by mass percentage (wt%). The composition is C: 0.68, Si: 1.08, Mn: 0.50, P: 0.012, S: 0.008, Cr: 0.25, Ni: 0.15, Cu: 0.03, Al: 0.025, Mo: 0.45, V: 0.20, Nb: 0.015, and the rest are iron. The continuous casting slab is heated in the heating furnace for a total of 330 minutes, the soaking section temperature is 1230-1250° C., the soaking section time is 260 minutes, and the intermediate slab is rolled.

[0028] 2. Intermediate billet heating

[0029] The intermediate billet that has been finished to remove surface defects and decarburized layers is heated in the furnace for 220 minutes. The temperature of the high temperature section is 1040-1080°C, the time of the high temperature section is 100 minutes, and the air-fuel ratio of the heating section and the high temperature section is 0.45.

[0030] 3. Intermediate billet rolling

[0031] Rolling is carried out by finishing rolling...

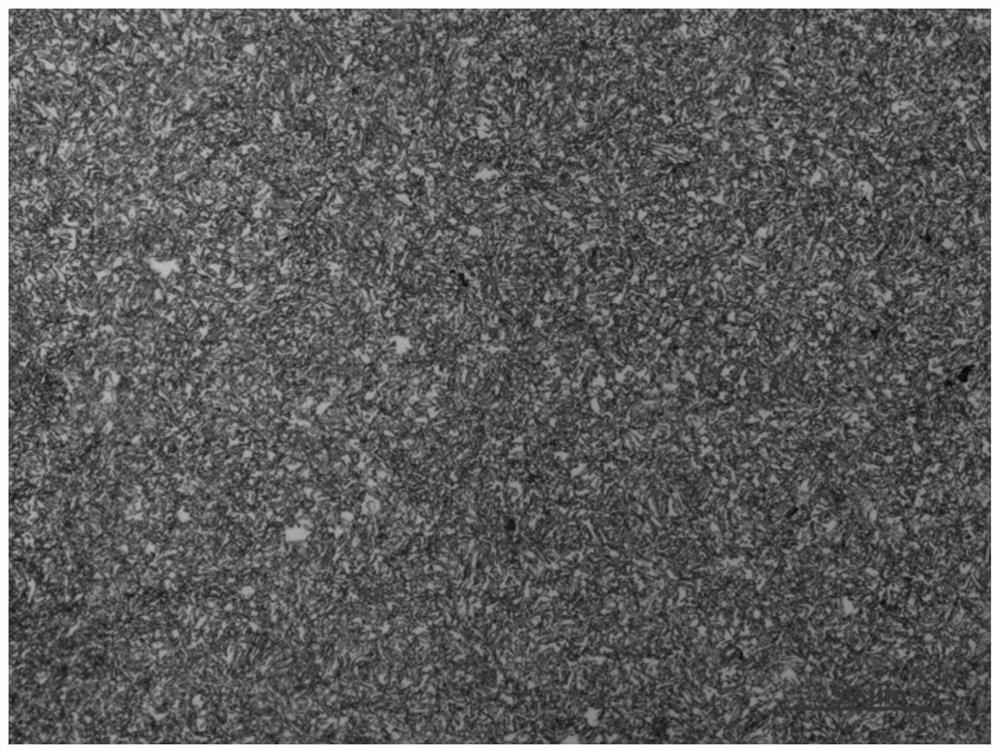

Embodiment 2

[0035] 1. Blank opening

[0036] The composition of the continuous casting slab is calculated by mass percentage (wt%). The composition is C: 0.68, Si: 1.08, Mn: 0.50, P: 0.012, S: 0.008, Cr: 0.25, Ni: 0.15, Cu: 0.03, Al: 0.025, Mo: 0.45, V: 0.20, Nb: 0.015, and the rest are iron. The continuous casting slab is heated in the heating furnace for a total of 350 minutes, the soaking section temperature is 1210-1240°C, the soaking section time is 280 minutes, and the intermediate slab is rolled.

[0037] 2. Intermediate billet heating

[0038] The intermediate billet that has been finished to remove surface defects and decarburized layers is heated in the furnace for 250 minutes, the temperature of the high temperature section is 1030-1050°C, the time of the high temperature section is 110 minutes, and the air-fuel ratio of the heating section and the high temperature section is 0.45.

[0039] 4. Intermediate billet rolling

[0040] Rolling is carried out by finishing rolling +...

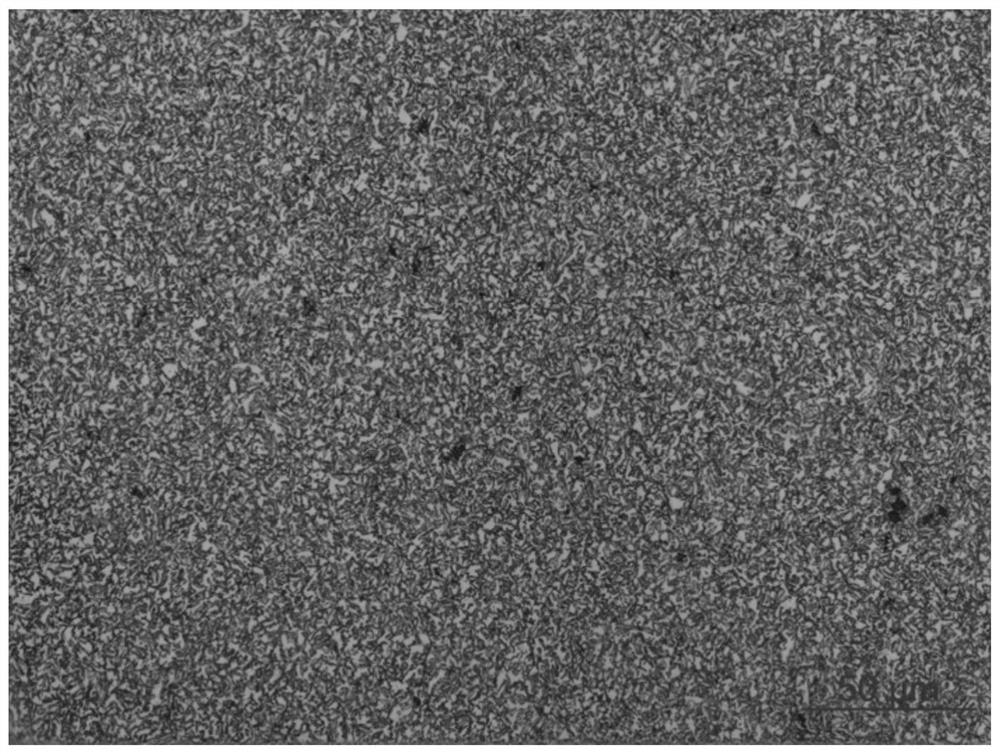

Embodiment 3

[0044] 1. Blank opening

[0045] The composition of the continuous casting slab is calculated by mass percentage (wt%). The composition is C: 0.68, Si: 1.08, Mn: 0.50, P: 0.012, S: 0.008, Cr: 0.25, Ni: 0.15, Cu: 0.03, Al: 0.025, Mo: 0.45, V: 0.20, Nb: 0.015, and the rest are iron. The continuous casting slab is heated in the heating furnace for a total of 400 minutes, the soaking section temperature is 1230-1250°C, the soaking section time is 290 minutes, and the intermediate slab is rolled.

[0046] 2. Intermediate billet heating

[0047] The intermediate blank that has been finished to remove surface defects and decarburized layers is heated in the furnace for 280 minutes, the temperature of the high temperature section is 1020-1040°C, the time of the high temperature section is 110 minutes, and the air-fuel ratio of the heating section and the high temperature section is 0.45.

[0048] 5. Intermediate billet rolling

[0049] Rolling is carried out by finishing rolling + MI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com