GaN-based laser diode epitaxial structure and preparation method thereof

A laser diode and epitaxial structure technology, applied in the structure of optical waveguide semiconductors, lasers, laser parts, etc., can solve the problems of high beam quality, narrow half-peak width, low beam quality, etc., and achieve the effect of high beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

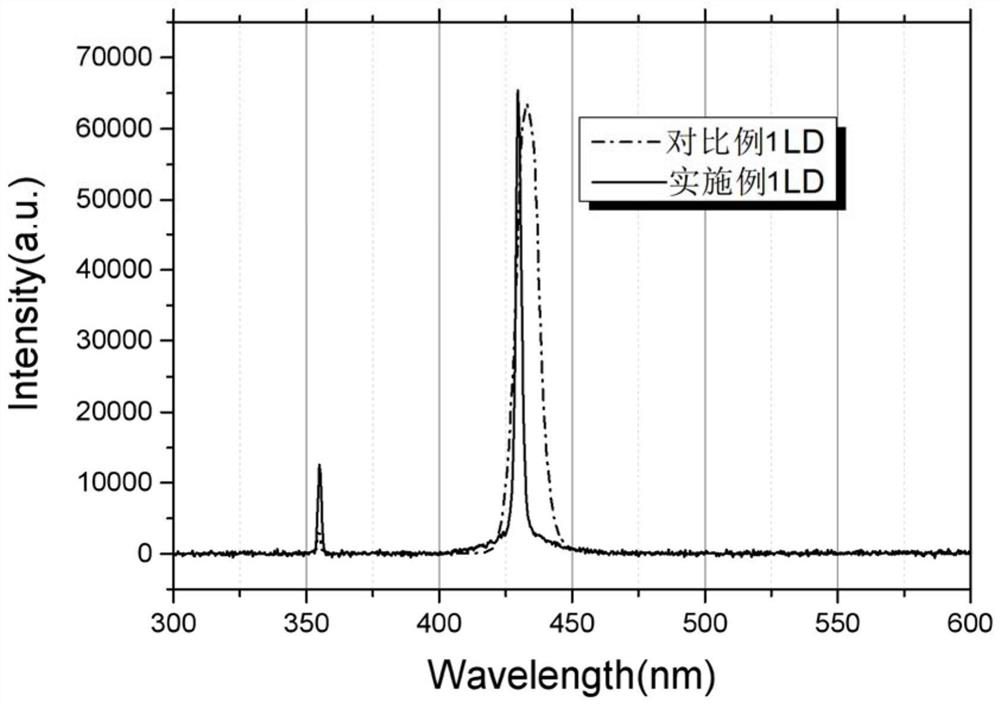

Embodiment 1

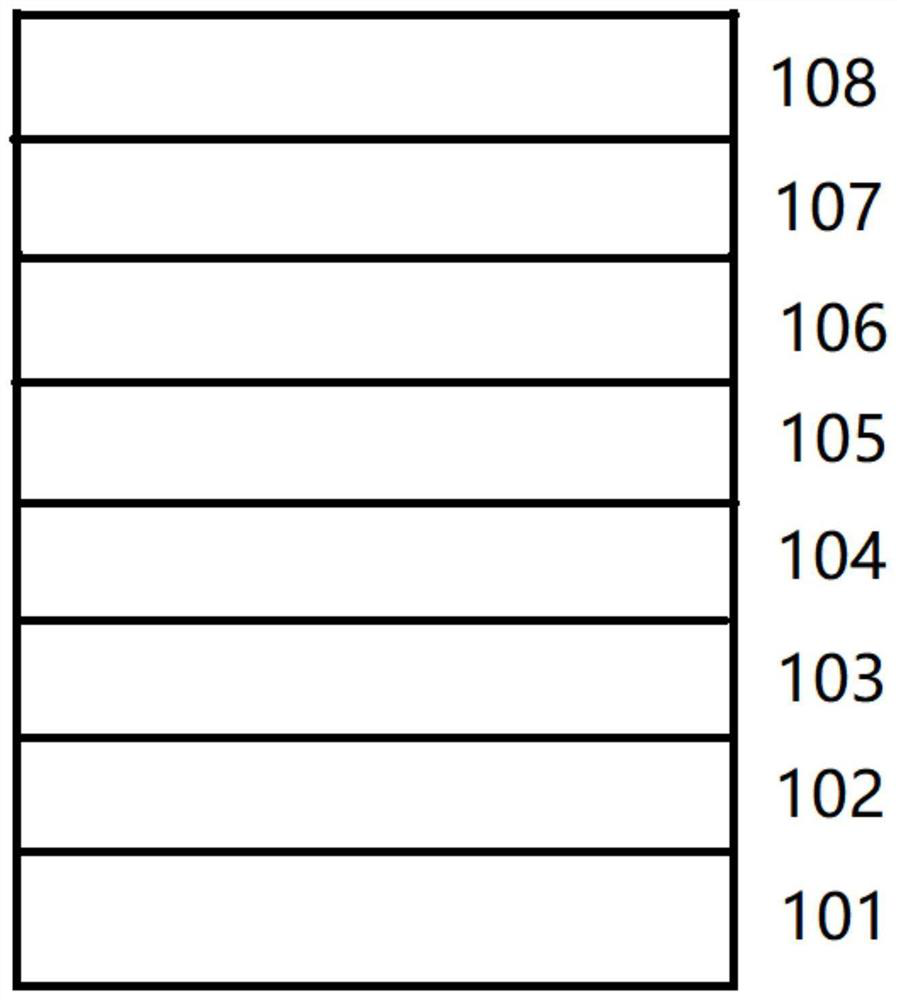

[0043] This embodiment provides a GaN-based laser diode epitaxial structure, such as figure 1 As shown, a gallium nitride single crystal substrate 101, an n-type GaN layer 102, an n-type confinement layer 103, a lower waveguide layer 104, an active region 105, an upper waveguide layer 106, and a p-type confinement layer are sequentially stacked from bottom to top. layer 107 and p-type GaN layer 108.

[0044] The preparation method and specific parameters of the GaN-based laser diode epitaxial structure are as follows:

[0045] S1. First in the metal organic compound vapor phase epitaxy reaction chamber, in hydrogen (H 2 ) atmosphere, the temperature was raised to 500°C, and NH was introduced into the reaction chamber 3 , and then heated to 1050°C, under hydrogen (H 2 ) and ammonia (NH 3 ) under a mixed atmosphere at a temperature of 1050° C., the surface of the GaN substrate is activated for 5 minutes.

[0046] S2. In hydrogen (H 2 ) atmosphere, on a GaN substrate, at a ...

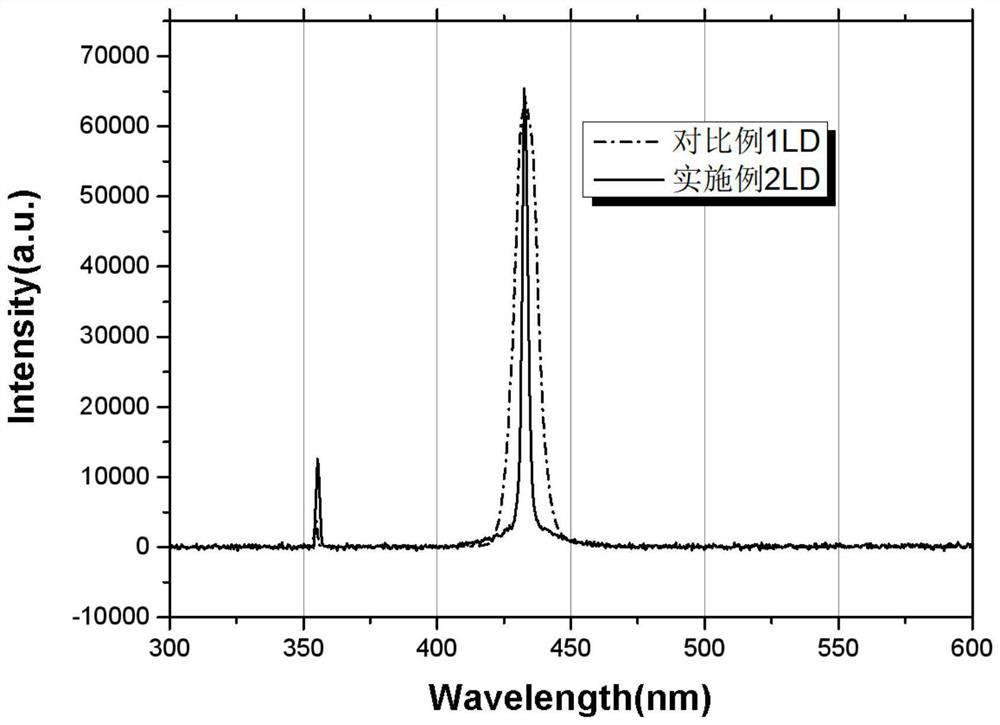

Embodiment 2

[0066] This embodiment provides a GaN-based laser diode epitaxial structure, such as figure 1 As shown, a gallium nitride single crystal substrate 101, an n-type GaN layer 102, an n-type confinement layer 103, a lower waveguide layer 104, an active region 105, an upper waveguide layer 106, and a p-type confinement layer are sequentially stacked from bottom to top. layer 107 and p-type GaN layer 108.

[0067] The preparation method and specific parameters of the GaN-based laser diode epitaxial structure are as follows:

[0068] S1. First in the metal organic compound vapor phase epitaxy reaction chamber, in hydrogen (H 2 ) atmosphere, the temperature was raised to 500°C, and NH was introduced into the reaction chamber 3 , and then heated to 1050°C, under hydrogen (H 2 ) and ammonia (NH 3 ) under a mixed atmosphere at a temperature of 1050° C., the surface of the GaN substrate is activated for 5 minutes.

[0069] S2. In hydrogen (H 2 ) atmosphere, on a GaN substrate, at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com