A dry-type denitrification superfine powder that realizes ultra-low emission of flue gas and its manufacturing method and application

A technology of ultra-fine powder and denitrification, which is applied in the field of denitrification, which can solve the problems of easy poisoning and failure of catalysts, high operating costs, and high construction costs, and achieve the effects of enhancing powder fluidity, reducing operating costs, and enhancing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

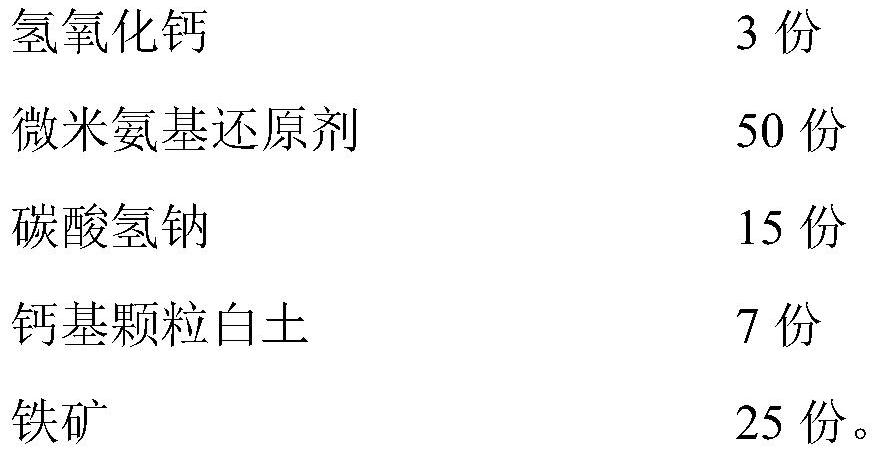

[0046] A dry-type denitrification superfine powder that cooperates to achieve ultra-low emission of flue gas in this embodiment has the following components:

[0047]

[0048]

[0049] Iron ore: The iron ore is mixed with hematite, pyrite and siderite in a mass ratio of 5:3:2.

Embodiment 2

[0051] A dry-type denitrification superfine powder that cooperates to achieve ultra-low emission of flue gas in this embodiment has the following components:

[0052]

Embodiment 3

[0054] A dry-type denitrification superfine powder that cooperates to achieve ultra-low emission of flue gas in this embodiment has the following components:

[0055]

[0056] Iron ore; the iron ore is mixed with hematite, pyrite and siderite in a mass ratio of 5:3:2.

[0057] The denitrification superfine powder manufacturing method of above-mentioned embodiment, it is to carry out according to the following steps:

[0058] 1. Weigh the iron ore fragments and grind them into fine powder through primary crushing (European jaw crusher), secondary crushing (hydraulic cone crusher), pre-grinding silo, vibrating feeder and (mechanical crusher) (200 mesh=75 micron), standby;

[0059] Wherein, the iron ore of embodiment 2 and 3 is mixed by hematite, pyrite and siderite, and the mass ratio of hematite fine powder, pyrite fine powder and siderite fine powder is 5 :3:2;

[0060] Two, take calcium hydroxide, sodium bicarbonate, calcium-based granule clay and amino reductant and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com