Preparation method and application of a PDMS and AAO double-layer embedded template for patterning polymer thin films

A technology of polymer film and patterning, applied in the direction of application, coating, flat products, etc., to achieve the effect of low cost, cheap price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

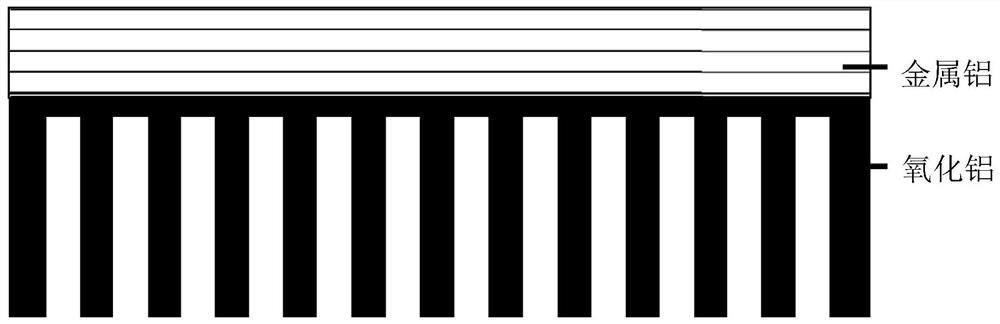

[0038] A method for preparing a PDMS and AAO double-layer embedded template in this embodiment comprises the following steps:

[0039] (1) Prepare 20mL of PDMS glue solution according to the formula ratio of PDMS glue solution of 5:1, and stir it with a stirrer for 0.5h at 0°C; then, put it in a vacuum drying oven and keep it under vacuum for 1h to eliminate Bubbles; after the bubbles are completely eliminated, store them in an airtight container at 0°C for later use.

[0040] (2) Double-pass anodized aluminum flakes were prepared by secondary anodization; high-purity aluminum flakes (purity: 99.999%, thickness: 0.3 mm) were used as raw materials, and washed in acetone and absolute ethanol solutions for 10 minutes respectively , and then dried; place the aluminum sheet in a muffle furnace at 450°C for 5 hours, and then cool it down to room temperature naturally; then, soak the aluminum sheet in 1mol / L sodium hydroxide solution for 15 minutes, and then wash it with deionized wa...

Embodiment 2

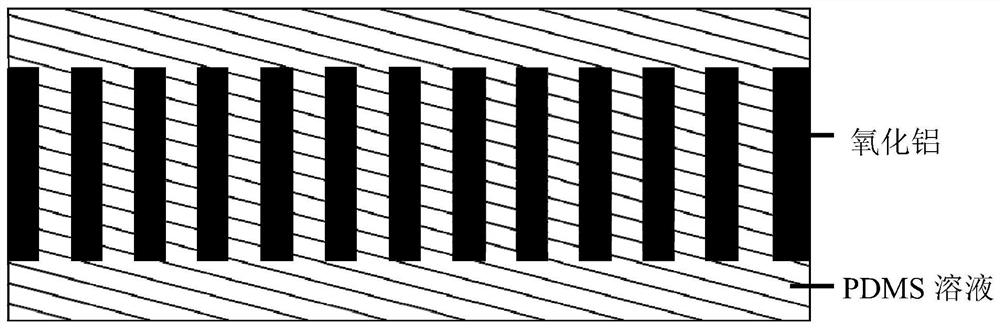

[0045] An application of the PDMS and AAO double-layer embedded template in the above-mentioned embodiment 1 of this embodiment, the PDMS and AAO double-layer embedded template is applied to the polymer film patterning:

[0046] (1) Prepare a polymer P3HT film with a thickness of 100nm by spin coating (spin coating speed 4000rpm), and place the side with the smooth hole structure of the PDMS and AAO double-layer embedded template and the polymer film face to face, as Figure 6 shown; then, at room temperature and 70bar pressure for 600s, such as Figure 7 As shown; finally, release the pressure, take out the template, and the polymer nanopillar film is successfully realized, as Figure 8 shown.

[0047] (2) Repeat the above steps to realize the preparation of large-area and batch-sized polymer P3HT nanocolumn films.

Embodiment 3

[0049] A method for preparing a PDMS and AAO double-layer embedded template in this embodiment comprises the following steps:

[0050] (1) Prepare 20mL of PDMS glue solution according to the formula ratio of PDMS glue solution of 5:1, and stir it with a stirrer for 0.5h at 0°C; then, put it in a vacuum drying oven and keep it under vacuum for 1h to eliminate Bubbles; after the bubbles are completely eliminated, store them in an airtight container at 0°C for later use.

[0051] (2) Double-pass anodized aluminum flakes were prepared by secondary anodization; high-purity aluminum flakes (purity: 99.999%, thickness: 0.3 mm) were used as raw materials, and washed in acetone and absolute ethanol solutions for 10 minutes respectively , and then dried; place the aluminum sheet in a muffle furnace at 450°C for 5 hours, and then cool it down to room temperature naturally; then, soak the aluminum sheet in 1mol / L sodium hydroxide solution for 15 minutes, and then wash it with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com