Silicon-containing negative electrode sheet and preparation method thereof and lithium ion secondary battery prepared from silicon-containing negative electrode sheet

A silicon negative electrode and silicon content technology, which is applied in the direction of secondary battery, negative electrode, electrode manufacturing, etc., can solve the problem of battery volume energy density limitation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

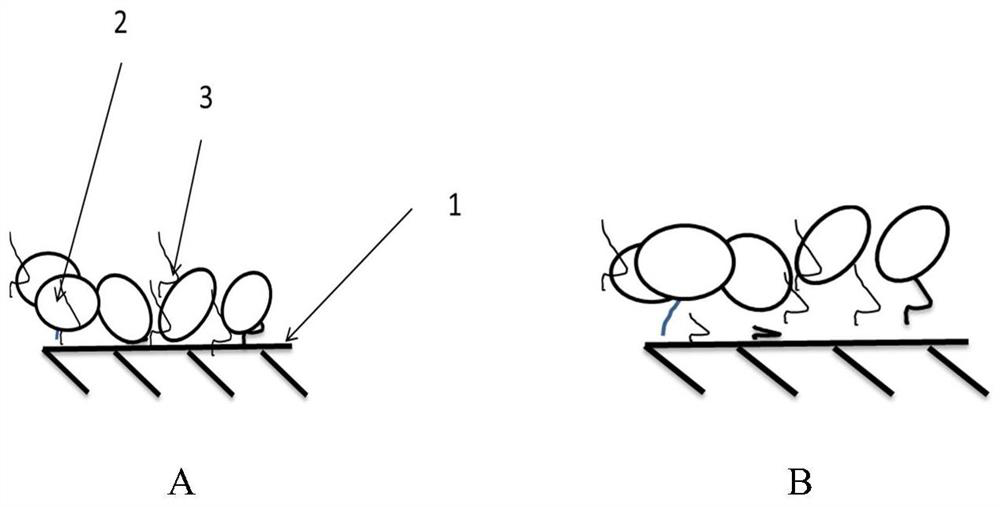

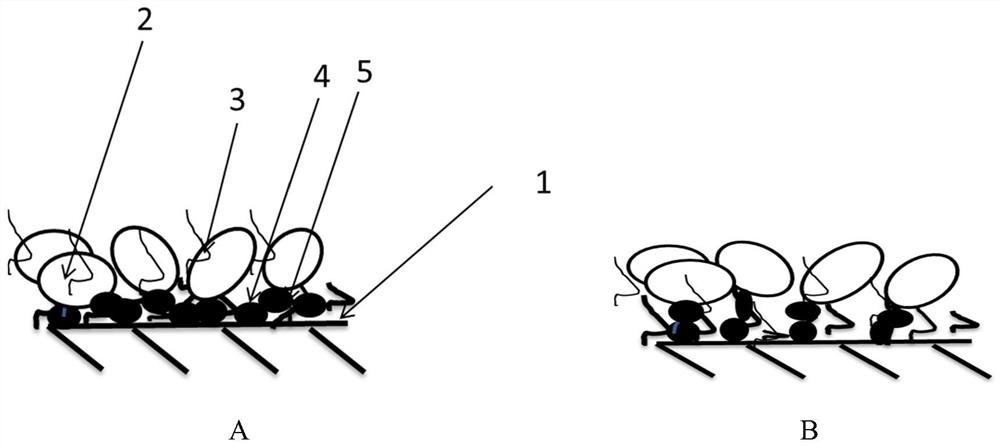

Image

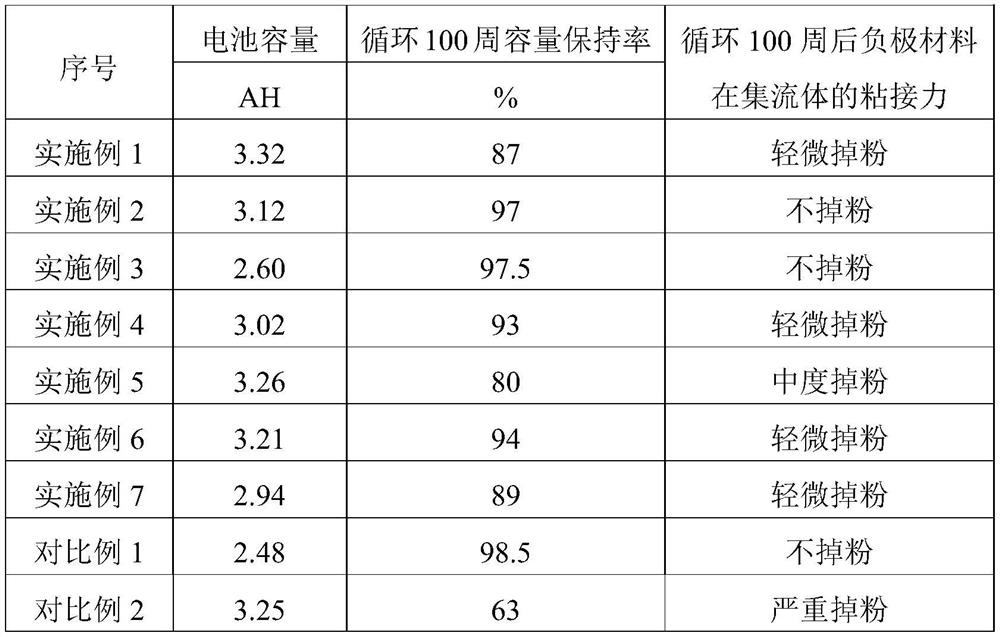

Examples

Embodiment

[0063] The specific manner of the present invention is described below with reference to specific embodiments, so as to make the technical content of the present invention clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

[0064] Reagents and Instruments

[0065] Materials, reagents, equipment, etc. used in the examples can be obtained from commercial sources unless otherwise specified. Unless stated otherwise, like terms refer to like materials.

[0066] The thickness test adopts the Japanese Mitutoyo Mitutoyo digital outer micrometer 193-111.

[0067] Stirring adopts the vacuum dual planetary mixer) HG-XJ-30A of Ross (Wuxi) Equipment Co., Ltd.

[0068] The test of battery capacity and capacity, and the test of cycle performance adopt the battery test point Bk-3512 of Guangzhou Lanqi Electronics Industry Co., L...

preparation example 1

[0070] Preparation Example 1: Production of Positive Electrode Sheet:

[0071] Dissolve the positive electrode material, conductive agent, and binder in N-methylpyrrolidone at a ratio of 97:1.5:1.5 and stir to make a slurry, and evenly coat it on the aluminum foil of the positive electrode current collector, dry it, and cut it after rolling , spot welding to make the positive plate of lithium-ion battery. The positive electrode material adopted in the embodiment is nickel manganese cobalt ternary (LiNi 1-x-y CoMnO 2 ) ternary material 811, the thickness after coating and rolling is 200 μm.

Embodiment 1

[0072] Embodiment 1: the making of silicon-containing negative electrode sheet

[0073] Preparation of Porous Composite Layer Slurry

[0074] Carbon black (average particle size is 0.3 μ m) as the conductive agent and the mixture of polyvinylidene fluoride PVDF and polymethyl acrylate as the mass ratio of the polymer material are 50:50 according to the conductive agent: polymer mixture dry powder mass ratio Disperse in water at a ratio of 30:70 to make a water-soluble suspension slurry of carbon black and polymer, with a solid content of 30wt%.

[0075] Preparation of silicon-containing negative electrode material slurry

[0076] The silicon-carbon composite material (purchased from Tianmu Pioneer Battery Material Technology Co., Ltd., with a capacity of 3000mAh / g and an average particle size of D50 of 0.1 μm) and artificial graphite (purchased from Beiterui New Material Group Co., Ltd. S360-L2, D50 =15 μm) was mixed according to 80:20 as silicon-containing negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com