Preparation method of polyimide composite electrode material containing ketone carbonyl bond chain structure

A polyimide and composite electrode technology, applied in structural parts, battery electrodes, circuits, etc., can solve the problems of sacrificial electrode material specific capacity, reduction of theoretical specific capacity, and unsatisfactory overall cycle performance, so as to avoid theoretical specific capacity Effect of reducing, reducing solubility, high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

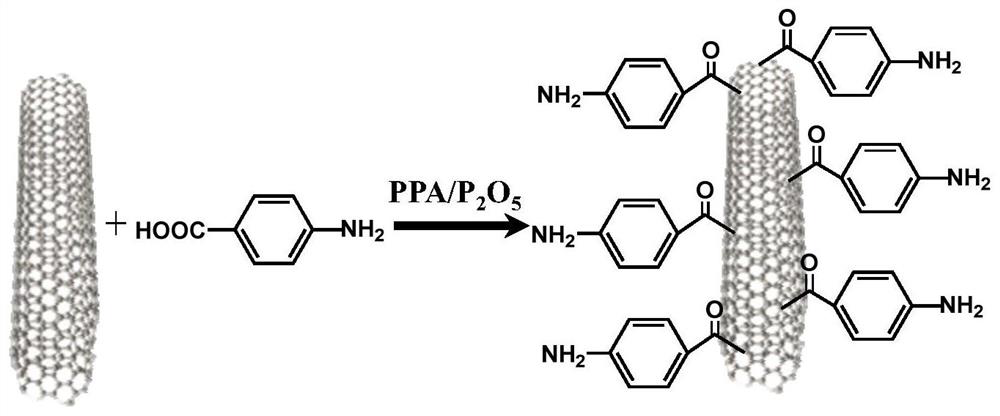

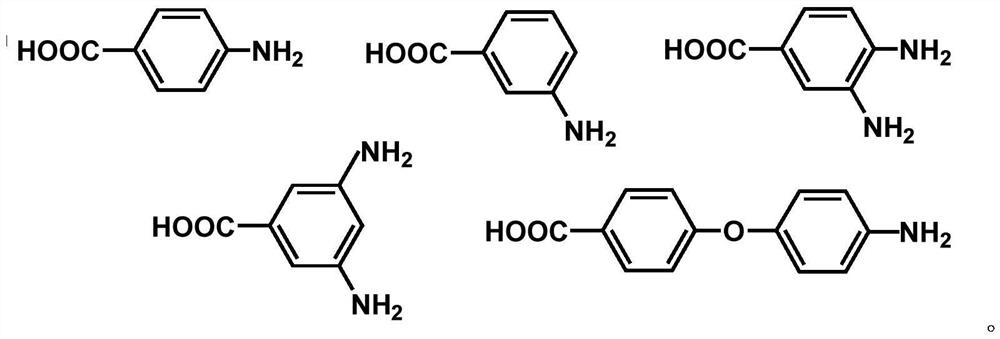

[0033] (1) 0.5g 4-amino-benzoic acid, 0.5g multi-walled carbon nanotubes (MWCNTs), 20g polyphosphoric acid (PPA) and 5g phosphorus pentoxide (P 2 o 5 ) into a 250ml three-necked flask in turn, and the reaction medium was heated and stirred under a nitrogen atmosphere. The reaction mixture was heated to 80°C for 1 hour, 100°C for 1 hour, and finally 130°C for 72 hours. After the reaction, the mixture was poured into distilled water. The resulting powdery product was filtered by suction and washed with dilute ammonium hydroxide, then Soxhlet extracted with deionized water for 3 days to remove residual reaction medium, and then Soxhlet extracted with methanol for 3 days to remove unreacted 4-amino-benzoic acid, Finally, dark brown aminated carbon nanotubes were obtained by freeze-drying.

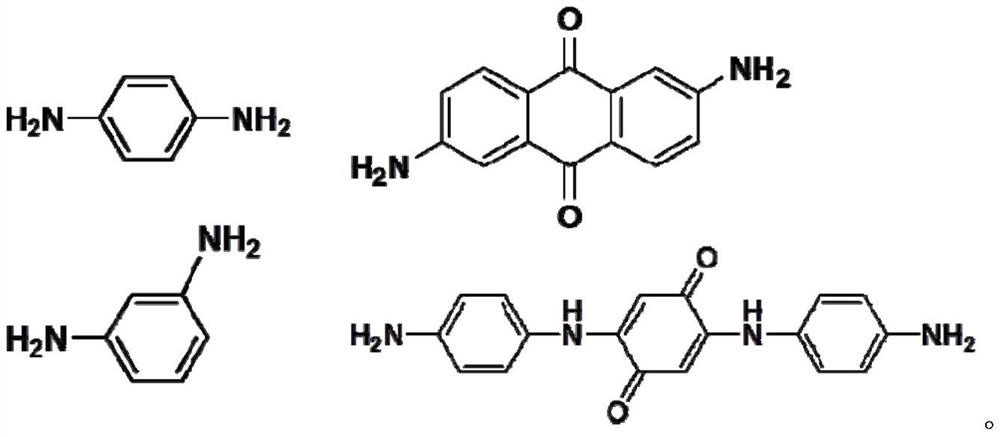

[0034] (2) Under nitrogen protection, ultrasonically disperse 0.5 g of the aminated carbon nanotubes obtained in step (1) in 100 mL of NMP in a 250 mL three-necked flask, and then add 1.16 g...

Embodiment 2

[0037] (1) 0.5g 4-amino-benzoic acid, 0.5g graphene oxide, 20g polyphosphoric acid (PPA) and 5g phosphorus pentoxide (P 2 o 5) into a 250ml three-necked flask in turn, and the reaction medium was heated and stirred under a nitrogen atmosphere. The reaction mixture was heated to 80°C for 1 hour, 100°C for 1 hour, and finally 130°C for 72 hours. After the reaction, the mixture was poured into distilled water. The resulting powdery product was filtered by suction and washed with dilute ammonium hydroxide, then Soxhlet extracted with deionized water for 3 days to remove residual reaction medium, and then Soxhlet extracted with methanol for 3 days to remove unreacted 4-amino-benzoic acid, Finally, dark brown aminated graphene oxide was obtained by freeze-drying.

[0038] (2) Under nitrogen protection, ultrasonically disperse 0.5 g of the aminated graphene oxide obtained in step (1) in 100 mL of DMF in a 250 mL three-necked flask, and then add 1.16 g of p-aminoanthraquinone, 1.09...

Embodiment 3

[0041] (1) 0.5g 4-amino-benzoic acid, 0.5g multi-walled carbon nanotubes (MWCNTs), 20g polyphosphoric acid (PPA) and 5g phosphorus pentoxide (P 2 o 5 ) into a 250ml three-necked flask in turn, and the reaction medium was heated and stirred under a nitrogen atmosphere. The reaction mixture was heated to 80°C for 1 hour, 100°C for 1 hour, and finally 130°C for 72 hours. After the reaction, the mixture was poured into distilled water. The resulting powdery product was filtered by suction and washed with dilute ammonium hydroxide, then Soxhlet extracted with deionized water for 3 days to remove residual reaction medium, and then Soxhlet extracted with methanol for 3 days to remove unreacted 4-amino-benzoic acid, Finally, dark brown aminated carbon nanotubes were obtained by freeze-drying.

[0042] (2) Under nitrogen protection, ultrasonically disperse 0.5 g of the aminated carbon nanotubes obtained in step (1) in 50 mL of NMP in a 100 mL three-necked flask, and then add 0.54 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com