Preparation method of nitrogen-modified porous carbon-coated cobalt nanoparticle catalyst

A particle catalyst, porous carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of large catalyst loss, large raw material consumption, small scope of action, etc., and achieve efficient degradation. , The process is simple, and the effect of improving activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

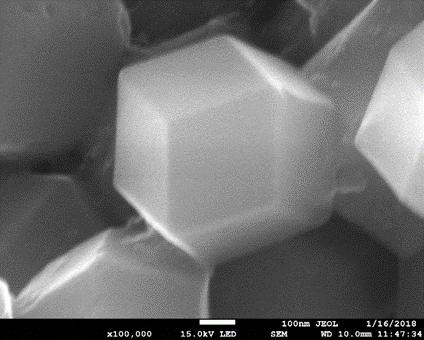

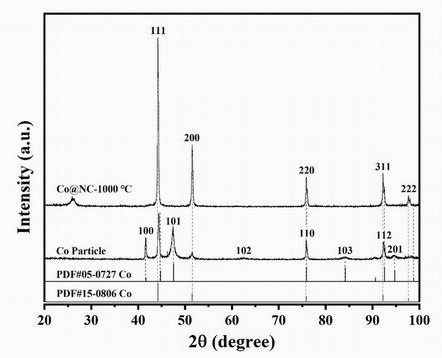

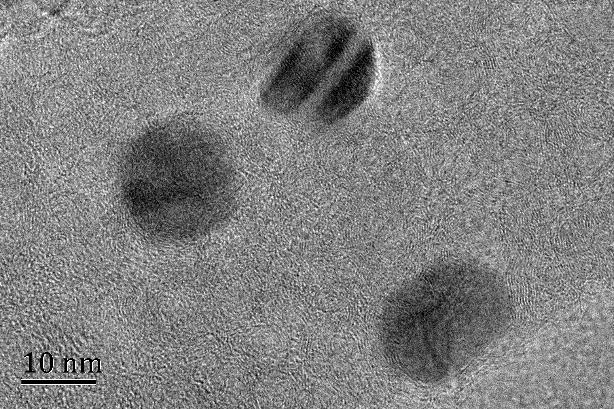

[0026] Example 1: Preparation of new Co@NC-900 ℃ catalyst

[0027] 1) Add 3 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 75 mL of methanol, and magnetically stirred for 5 min to form solution A;

[0028] 2) Dissolve 12 mmol 2-methylimidazole (2-Methylimidazole) in 75 mL methanol, shake manually for 5 min, and prepare solution B;

[0029] 3) Slowly pour solution B into solution A, the solution turns from pink to deep purple, stir for 10 min, and let stand for 24 h;

[0030] 4) Pour off the supernatant in 3), collect the solid at the bottom of the beaker, centrifuge at 8000 rpm for 15 min, take the solid and add 50 mL of methanol, vortex for 5 min, centrifuge again, and repeat washing 3 times;

[0031] 5) Dry the cleaned sample at 60 °C for 12 h under vacuum to obtain the precursor ZIF-67;

[0032] 6) Weigh 0.2 g ZIF-67 in the crucible of the oxidation furnace, and calcinate it in a nitrogen atmosphere at 900 °C for 2 h to obtain Co@NC-900 °C;

[0033] 7) For catalytic materi...

Embodiment 2

[0038]Example 2: New Co@NC-900 ℃ catalyst activates persulfate to degrade phenol (Phenol)

[0039] In order to investigate the degradation efficiency of the new Co@NC-900 ℃ catalyst on phenolic substances, the representative phenol (Phenol) was selected as the target pollutant. Prepare 10 mmol / L Phenol stock solution, 50 mmol / L potassium persulfate (PMS) stock solution and 0.2 mol / L boric acid / borax buffer solution (pH 7.2) with deionized water; add 10 mLPhenol stock solution, 15 mL PMS stock solution, 25 mL buffer solution, deionized water, where Phenol and PMS were placed separately before starting the reaction, and the pH of the reaction system was adjusted to 7.2, and the temperature of the reaction system was controlled; Add 0.005g of the catalyst to be tested in the Phenol part of the system, pour the PMS part into it quickly and mix, start timing, place the reaction device (conical flask) in a constant temperature shaker, take samples at regular intervals, and pour them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com