Carbon nitride/bismuth oxychloride/tungsten oxide heterojunction photocatalyst as well as preparation method and application thereof

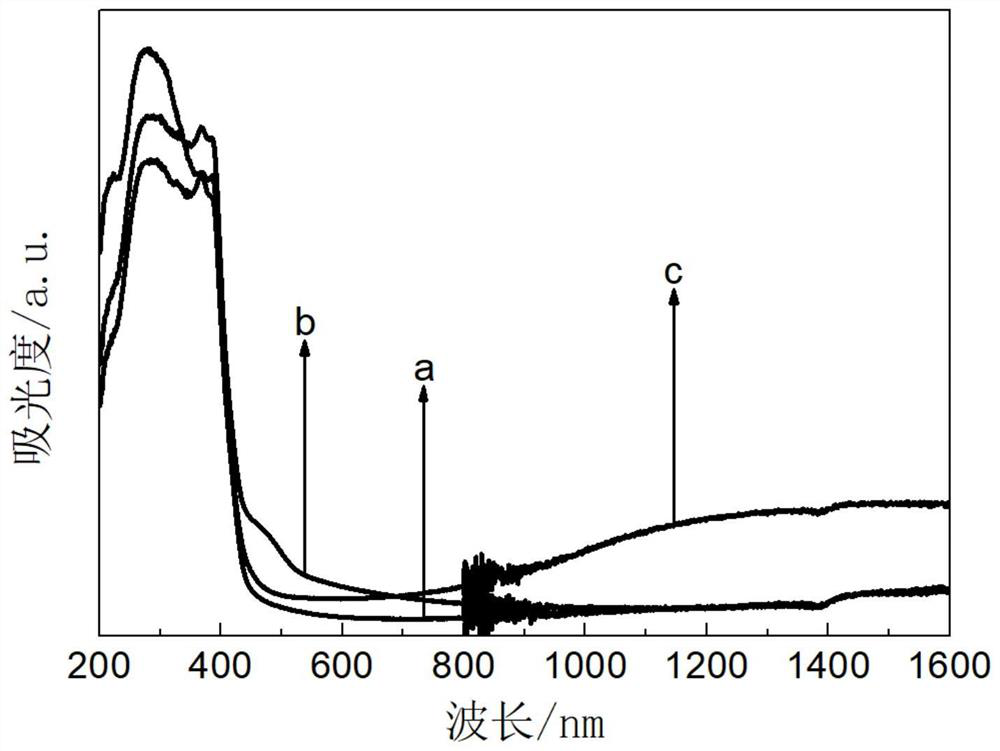

A technology of bismuth oxychloride and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve disadvantages and other problems, and achieve the effects of enhancing light absorption, enhancing light absorption, and improving light absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

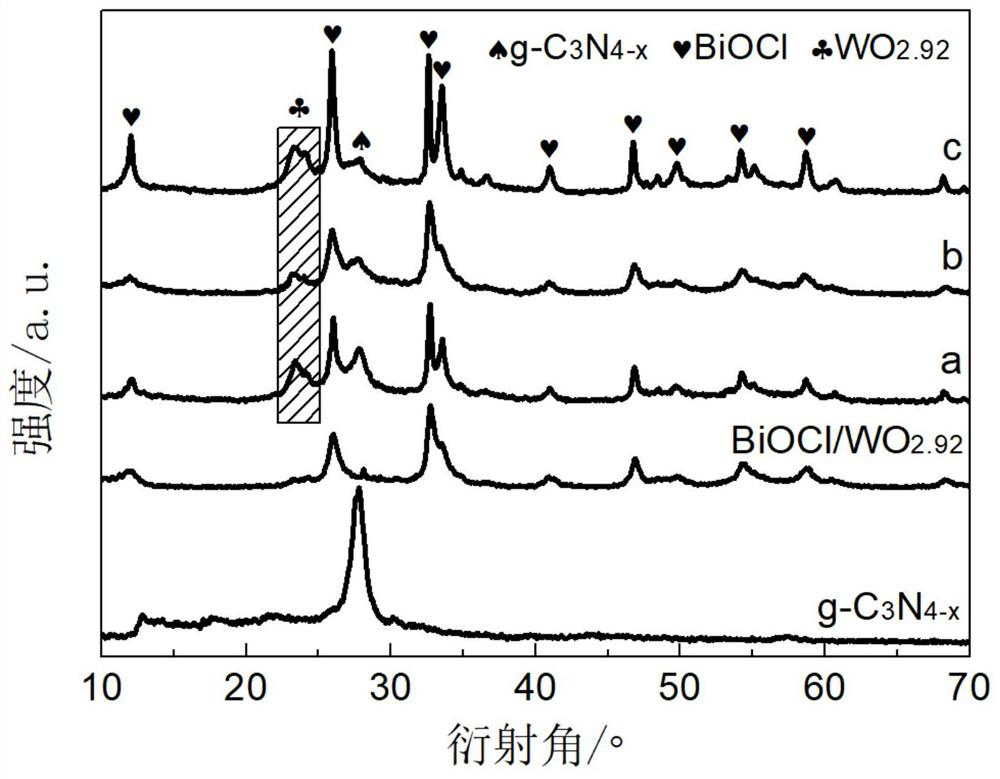

[0027] A preparation method of carbon nitride / bismuth oxychloride / tungsten oxide heterojunction photocatalyst of the present invention comprises the following steps:

[0028] Step 1: Put 30g of urea in a quartz crucible with a cover, place the crucible in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 15°C / min, keep it warm for 4 hours, and then cool it down to 50°C with the furnace , to give g-C with nitrogen vacancies 3 N 4-x Powder;

[0029] Step 2: Add a certain amount of g-C 3 N 4-x and WCl 6 Disperse the powder in 40mL of absolute ethanol, stir for 30min, and ultrasonicate for 60min to obtain a blue suspension;

[0030] Step 3: While magnetically stirring, a certain amount of NaBiO 3 Disperse the powder in the suspension, and stir for 30 minutes to obtain a light brown suspension, which is the reaction precursor, and the molar ratio of Bi and Cl in the reaction precursor is (0.15-0.5):1;

[0031] Step 4: Put the reaction precur...

Embodiment 1

[0035] Step 1: Put 30g of urea in a quartz crucible with a cover, place the crucible in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 15°C / min, keep it warm for 4 hours, and then cool it down to 50°C with the furnace , to give g-C with nitrogen vacancies 3 N 4-x Powder;

[0036] Step 2: Add 0.3g of g-C 3 N 4-x and 0.225g of WCl 6 Disperse the powder in 40mL of absolute ethanol, stir for 30min, and ultrasonicate for 60min to obtain a blue suspension;

[0037] Step 3: While stirring magnetically, mix 0.238 g of NaBiO 3Disperse the powder into the above suspension, the molar ratio of Bi element to Cl element is 0.25:1, after stirring for 30 minutes, a light brown suspension is obtained, which is the reaction precursor;

[0038] Step 4: Place the reaction precursor solution in a hydrothermal reaction kettle with a reaction filling ratio of about 65%, raise the temperature from room temperature to 140°C in 60 minutes, and finish the react...

Embodiment 2

[0041] Step 1: Put 30g of urea in a quartz crucible with a cover, place the crucible in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 15°C / min, keep it warm for 4 hours, and then cool it down to 50°C with the furnace , to give g-C with nitrogen vacancies 3 N 4-x Powder;

[0042] Step 2: Add 0.3g of g-C 3 N 4-x and 0.225g of WCl 6 Disperse the powder in 40mL of absolute ethanol, stir for 30min, and ultrasonicate for 60min to obtain a blue suspension;

[0043] Step 3: While stirring magnetically, dissolve 0.476 g of NaBiO 3 Disperse the powder into the above suspension, the molar ratio of Bi element to Cl element is 0.5:1, after stirring for 30 minutes, a light brown suspension is obtained, which is the reaction precursor;

[0044] Step 4: Place the reaction precursor solution in a hydrothermal reactor with a reaction filling ratio of about 80%, raise the temperature from room temperature to 160°C in 60 minutes, and finish the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com