Self-supporting graphene manganese dioxide nanowire composite film electrode and preparation method thereof

A manganese dioxide nano-composite film technology, which is applied in graphene, hybrid capacitor electrodes, manganese oxide/manganese hydroxide, etc., can solve the problems of low electrochemical performance and general mass specific capacitance, and improve electrochemical performance , Environmentally friendly theoretical capacitance, the effect of enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

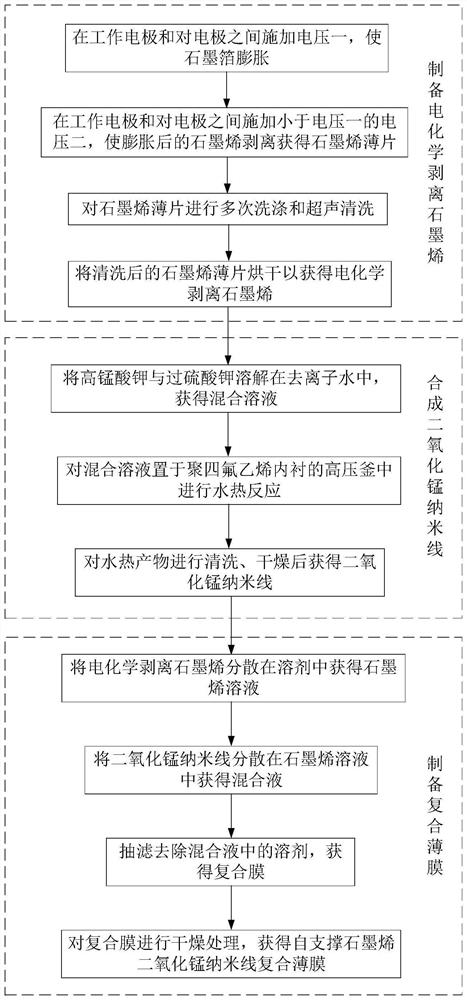

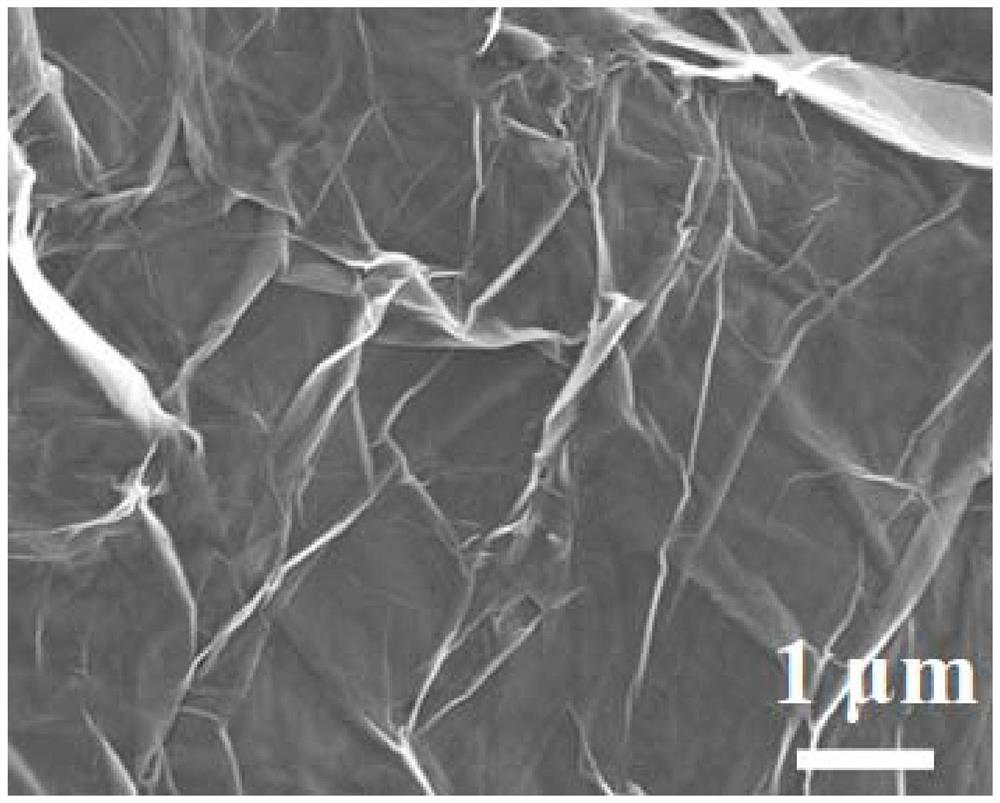

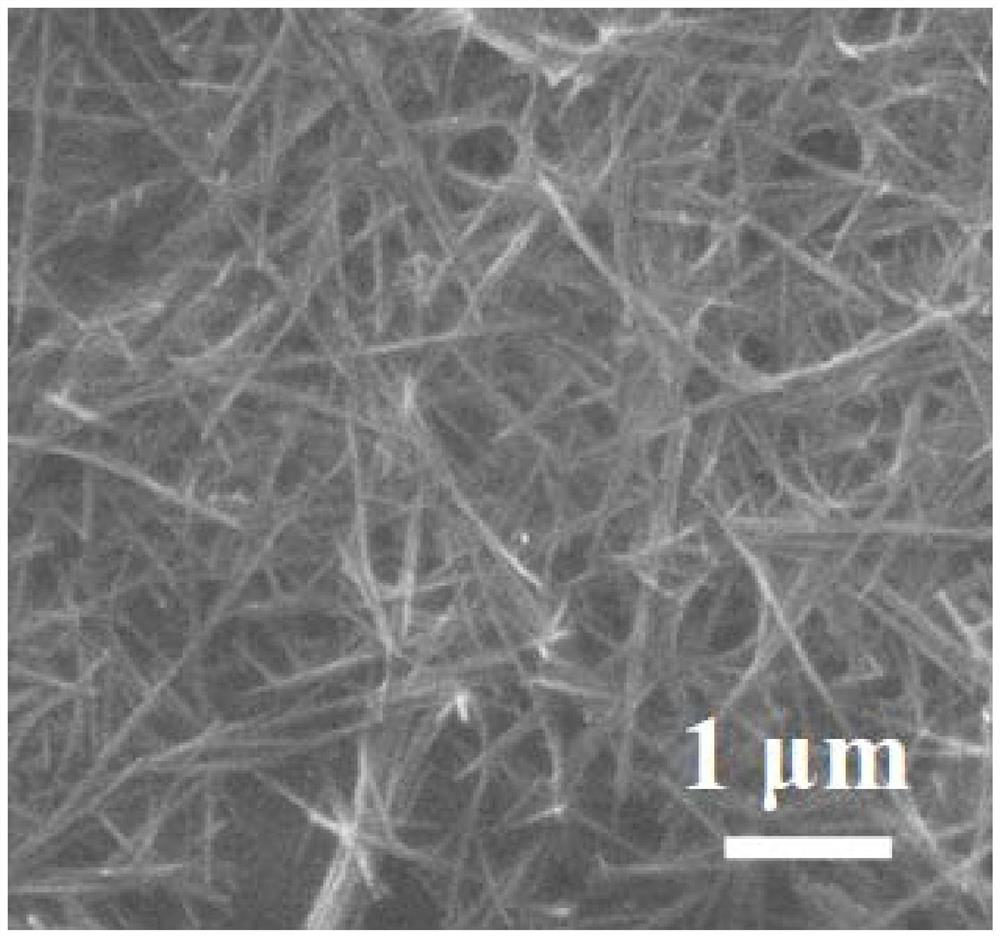

[0035] see figure 1 , This embodiment provides a method for preparing a self-supporting graphene-manganese dioxide nanowire composite film electrode. The preparation method combines electrochemically exfoliated graphene with manganese dioxide nanowires to obtain a composite film electrode. Since graphene has a large specific surface area, excellent electrical conductivity, good chemical properties and mechanical properties, it is a very good choice to prepare self-supporting flexible electrode materials with graphene. This embodiment is based on graphene-based flexible self-supporting supercapacitor electrodes, and makes it have higher specific capacitance. Composite transition metal oxides with pseudocapacitive charge storage capability and self-supporting graphene can be designed to obtain composite thin-film electrode materials with very good performance through rational design. Based on this, the preparation method of this embodiment is mainly carried out from the followi...

Embodiment 2

[0053] This embodiment provides a preparation method of a self-supporting graphene manganese dioxide nanowire composite film electrode, which is similar to the preparation method in Example 1, the difference is that the MnO 2 The mass ratio of the mass to the composite film is 30%. Composite thin film material tested 1mA / cm by cyclic charging and discharging 2 Under the current density, the specific capacitance is 767mF / cm 2 , which can meet the electrode conductivity requirements of supercapacitors in some special cases.

Embodiment 3

[0055] This embodiment provides a preparation method of a self-supporting graphene manganese dioxide nanowire composite film electrode, which is similar to the preparation method in Example 1, the difference is that the MnO 2 The weight accounts for 10% of the weight of the composite film. Composite materials tested 1mA / cm by cyclic charge and discharge 2 Under the current density, the specific capacitance is 476mF / cm 2 , which can meet the electrode conductivity requirements of supercapacitors in some special cases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com