Construction method and application of interface catalytic oxidation film suitable for algae-water separation

A technology of catalytic oxidation and algal water separation, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve problems such as membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

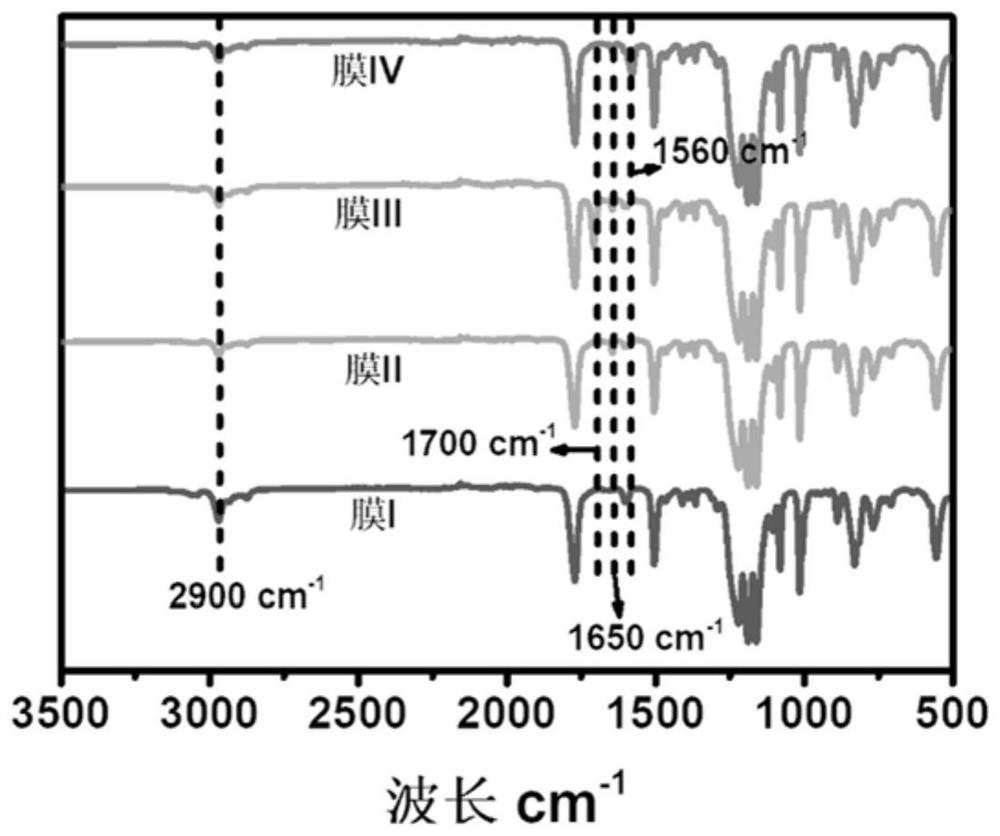

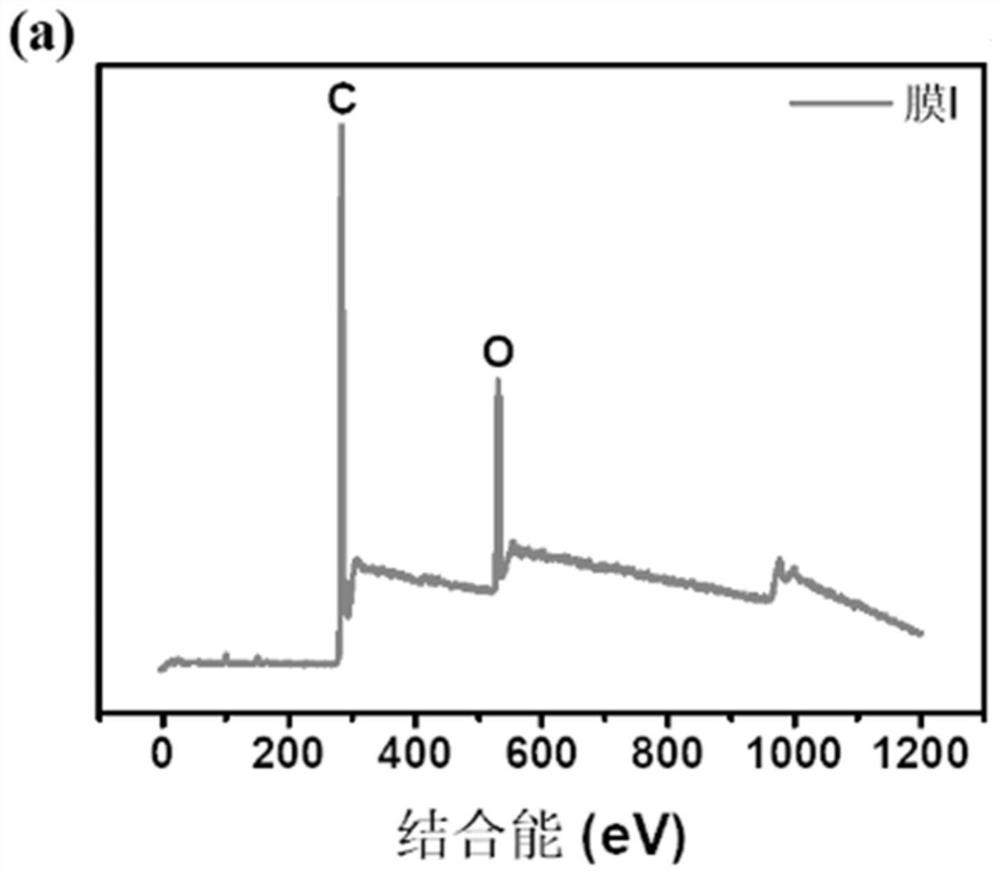

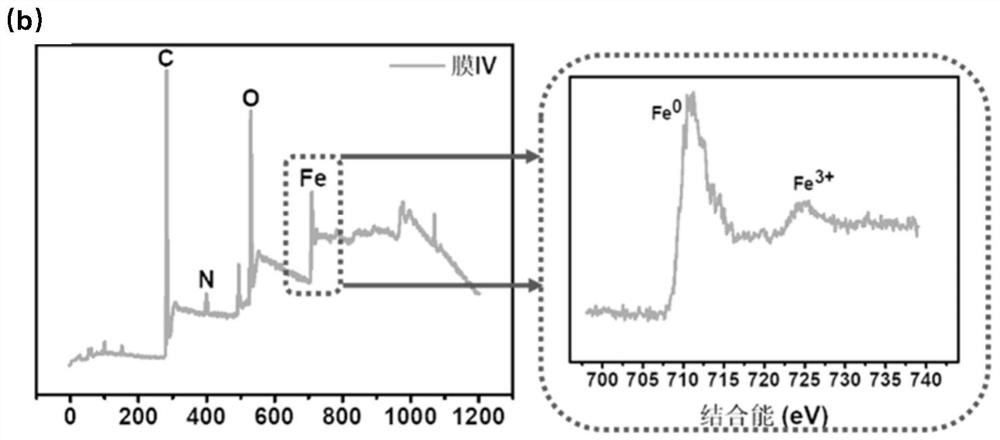

[0044] Example 1: The preparation of a microfiltration membrane with nanometer zero-valent iron loading is completed in the following steps

[0045] (1) Clean the base film

[0046] Soak the purchased polycarbonate (PC) membrane with an average pore diameter of 0.4 μm in deionized water for 12 hours to obtain Membrane I.

[0047] (2) Coating polydopamine / polypropyleneimine layer

[0048] Soak the membrane I obtained in step (1) with absolute ethanol for 5 minutes, then immerse in the solution I, and vibrate at a speed of 50r / min for 12 hours, take it out and rinse it with deionized water for 5 minutes, and the membrane can be obtained II.

[0049] Solution I in step (2) is a mixed aqueous solution of dopamine hydrochloride and polyethyleneimine, and the pH value of the mixed solution is controlled at 7 with 10 mM Tris-HCl buffer solution. The concentration of dopamine hydrochloride is 1g / L, and the concentration of polyethyleneimine is 1g / L. The water used to configure the...

Embodiment 2

[0058] Embodiment 2: The preparation of microfiltration membrane with nanometer zero valent iron loading is completed according to the following steps

[0059] (1) Clean the base film

[0060] The purchased polycarbonate (PC) membrane with an average pore diameter of 0.4 microns was soaked in deionized water for 24 hours to obtain membrane I.

[0061] (2) Coating polydopamine / polypropyleneimine layer

[0062] Soak the membrane I obtained in step (1) with absolute ethanol for 15 minutes, then immerse in the solution I, and vibrate at a speed of 100r / min for 24 hours, take it out and rinse it with deionized water for 10 minutes, and the membrane can be obtained II.

[0063] Solution I in step (2) is a mixed aqueous solution of dopamine hydrochloride and polyethyleneimine, and the pH value of the mixed solution is controlled at 8 with 50 mM Tris-HCl buffer solution. The concentration of dopamine hydrochloride is 5g / L, and the concentration of polyethyleneimine is 10g / L. The w...

Embodiment 3

[0072] Embodiment 3: the preparation has the microfiltration membrane of nanometer zero-valent iron loading to be finished according to the following steps

[0073] (1) Clean the base film

[0074] The purchased polycarbonate (PC) membrane with an average pore diameter of 0.4 μm was immersed in deionized water for 72 hours to obtain membrane I.

[0075] (2) Coating polydopamine / polypropyleneimine layer

[0076] Soak the membrane I obtained in step (1) with absolute ethanol for 30 minutes, then immerse in the solution I, and vibrate at a speed of 200r / min for 48 hours, take it out and rinse it with deionized water for 20 minutes, and the membrane can be obtained II.

[0077] Solution I in step (2) is a mixed aqueous solution of dopamine hydrochloride and polyethyleneimine, and the pH value of the mixed solution is controlled at 10 with 100 mM Tris-HCl buffer solution. The concentration of dopamine hydrochloride was 10g / L, and the concentration of polyethyleneimine was 15g / L....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com