A kind of preparation method of silicon-based wide-spectrum photodetector

A photodetector and wide-spectrum technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low detection efficiency, achieve high detection efficiency and improve device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

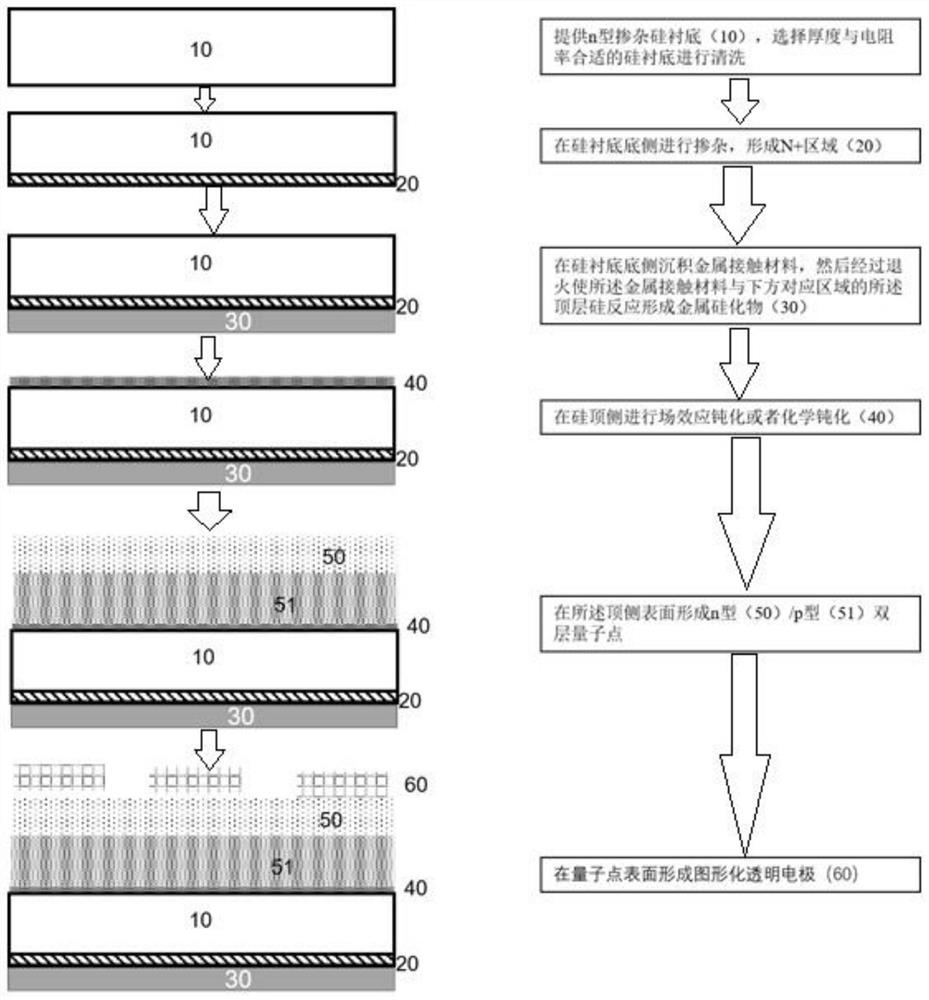

[0049] The present embodiment provides a preparation method of a silicon-based wide-spectrum photodetector, and the specific steps are as follows:

[0050] (1) Provide an n-type doped silicon substrate, which is a P-doped semiconductor (Si), 100 crystal planes, selected thickness of 0.5 mm, and resistivity of 1-10 Ω.cm; Standard RCA process cleaning and 1:20 (HF:H 2 Rinse with HF solution in a volume ratio of O=1:20 to remove the natural oxide layer;

[0051] (2) Doping P ions on the bottom side of the silicon substrate with a doping concentration of 5×10 15 cm -2 , the doping energy is 20keV, the N+ region is formed and the lattice damage is eliminated by annealing at 1000℃ for 5s (need to be carried out under the protection of vacuum environment or inert atmosphere);

[0052] (3) in N + The metal contact material Al is deposited on the bottom side of the region by electron beam evaporation, with a thickness of 100 nm, and then annealed at 400 ° C (need to be carried out ...

Embodiment 2

[0059] (1) Provide an n-type doped silicon substrate, the substrate includes, P-doped Si, 100 crystal plane, the selected thickness is 0.5mm, and the resistivity is 1-10Ω.cm; standard RCA is performed for a suitable silicon substrate Process cleaned and washed with 1:20 (HF:H 2 Rinse with HF solution in a volume ratio of O=1:20 to remove the natural oxide layer;

[0060] (2) Growth of barrier layer SiO by CVD method on the front side of silicon substrate 2 , its thickness is 500nm;

[0061] (3) Diffusion the silicon wafer, the diffusion temperature is 700°C, the diffusion time is 5min, and the diffusion furnace needs to be protected with an inert gas;

[0062] (4) Use 1:10 (HF:H 2 O=1:10 volume ratio) HF solution will SiO 2 Rinse off, the processing time is about 10 minutes;

[0063] (3) in N + The bottom side of the region is deposited by electron beam evaporation, the metal contact material Al, with a thickness of 100nm, is then annealed at 400 °C under the protection ...

Embodiment 3

[0068] (1) Provide an n-type doped silicon substrate, the substrate includes, P-doped Si, 100 crystal plane, the selected thickness is 0.5mm, and the resistivity is 1-10Ω.cm; standard RCA is performed for a suitable silicon substrate Process cleaned and washed with 1:20 (HF:H 2 Rinse with HF solution in a volume ratio of O=1:20 to remove the natural oxide layer;

[0069] (2) Doping P ions on the bottom side of the silicon substrate with a doping concentration of 5×10 15 cm -2 , the doping energy is 20keV, the N+ region is formed and the lattice damage is eliminated by annealing at 1000℃ for 5s under the protection of vacuum environment or inert atmosphere;

[0070] (3) in N + The bottom side of the region is deposited by electron beam evaporation, the metal contact material Al, with a thickness of 100nm, is then annealed at 400 °C under the protection of a vacuum environment or an inert atmosphere for 30s, and the metal silicon is reacted on the silicon surface to form meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com