Device and method for preparing silicon dioxide and polycrystalline silicon films on surface of silicon wafer

A technology of polysilicon thin film and silicon dioxide, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve problems such as high cost, impact on industrial development, immature polysilicon film technology, etc., and achieve low cost, The effect of cheap target material and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

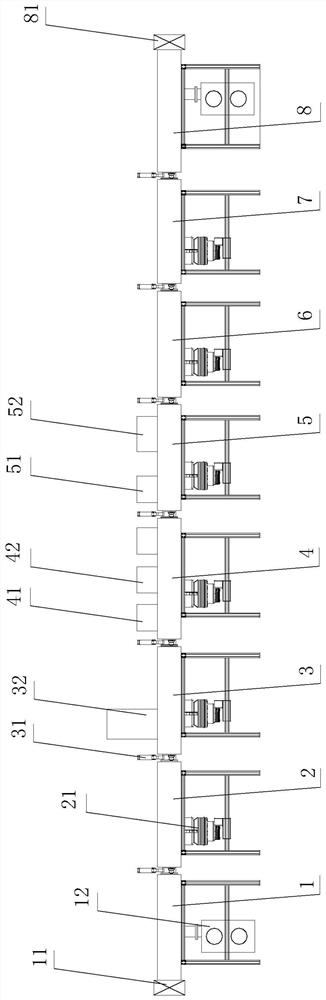

[0036] see figure 1 , a device for preparing silicon dioxide and polysilicon films on the surface of a silicon wafer, including an inlet pre-pumping chamber 1, an inlet transition chamber 2, an oxidation chamber 3, a process chamber 4, a tempering chamber 5, a cooling chamber 6, The outlet buffer chamber 7, the outlet chamber 8, and the connection between any two adjacent chambers are provided with a vacuum isolation flapper valve 31, and the front side of the inlet pre-pumping chamber 1 is provided with a first flap valve 11 , the rear side of the outlet chamber 8 is provided with a second flap valve 81, the inlet pre-pumping chamber 1 and the outlet chamber 8 are connected with a vacuum pump 12, the inlet transition chamber 2, the oxidation chamber 3, the process chamber 4 , the tempering chamber 5, the cooling chamber 6, and the outlet buffer chamber 7 are all connected with a turbomolecular pump 21, and the oxidation chamber 3 is connected with a low-energy oxygen ion sour...

Embodiment 2

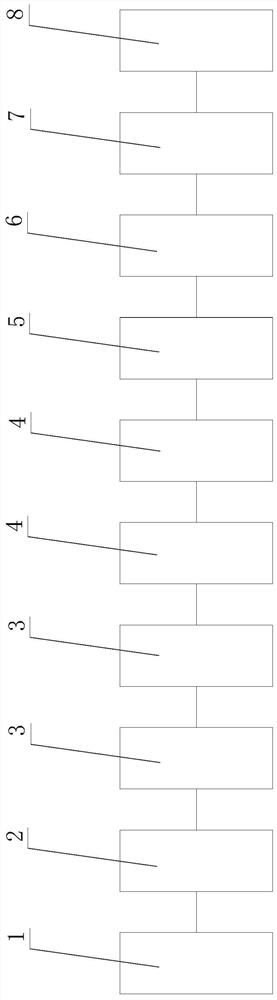

[0040] see figure 2 , a device for preparing silicon dioxide and polysilicon films on the surface of a silicon wafer, including an inlet pre-pumping chamber 1, an inlet transition chamber 2, two oxidation chambers 3, two process chambers 4, a tempering chamber 5, The cooling chamber 6, the outlet buffer chamber 7, the outlet chamber 8, and the connection between any two adjacent chambers are provided with a vacuum isolation plug valve 31, and the front side of the inlet pre-pumping chamber 1 is provided with a first The flap valve 11, the rear side of the outlet chamber 8 is provided with a second flap valve 81, the inlet pre-pumping chamber 1 and the outlet chamber 8 are connected with a vacuum pump 12, the inlet transition chamber 2, the oxidation chamber 3 , the process chamber 4, the tempering chamber 5, the cooling chamber 6, and the outlet buffer chamber 7 are all connected with a turbomolecular pump 21, and the oxidation chamber 3 is connected with a low-energy oxygen ...

Embodiment 3

[0044] Prepare the preparation method of silicon dioxide and polysilicon thin film on the surface of silicon chip, comprise the following steps:

[0045] (1) arrange the silicon wafers in a determinant on the graphite tray;

[0046] (2) Open the first flap valve, the graphite tray loaded with silicon wafers first enters the inlet pre-pumping chamber, and the air pressure is reduced from normal pressure to 1pa under the action of the vacuum pump;

[0047] (3) Open the vacuum isolation plug valve between the inlet pre-pumping chamber and the inlet transition chamber to send the graphite tray loaded with silicon wafers into the inlet transition chamber, and then close the vacuum isolation plug between the inlet pre-pumping chamber and the inlet transition chamber The plate valve, under the action of the turbomolecular pump, reduces the air pressure to 10 -2 pa;

[0048] (4) Open the vacuum isolation slide valve between the inlet transition chamber and the oxidation chamber to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com