Circulating water electrochemical treatment device and method

A technology for chemical treatment and circulating water, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of zero emission and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

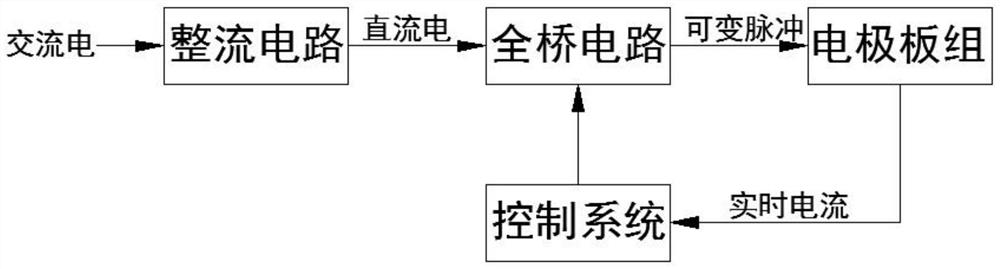

[0025] see figure 1 As shown, the present invention will be further described below through specific embodiments.

[0026] The present invention relates to a circulating water electrochemical treatment device, comprising:

[0027] The cold water pool is used to store circulating water and buffer water consumption;

[0028] The electrode plate group is used to electrolyze the circulating water. At the same time, the real-time current data of the motor plate group is collected and sent to the control system for processing. Each electrode plate group is composed of anode sheets and cathode sheets, and there are more cathode sheets than anode sheets. Each electrode plate group in this embodiment includes two anode sheets and three cathode sheets, wherein the anode sheets and the cathode sheets are arranged alternately in parallel with each other, and the number of electrode sheets has a positive relationship with the amount of treated water;

[0029] The power supply device is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com