A charge structure for blast furnace smelting ultra-high ratio vanadium-titanium magnetite

A vanadium titanomagnetite and blast furnace smelting technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of increased sulfur load in the furnace and reduced sulfur capacity of slag, and achieves suppression of foaming, increased proportion, and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be further described below with reference to the accompanying drawings and examples.

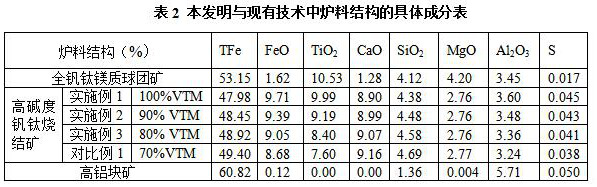

[0033] First, the ultra-high ratio for a blast furnace charge vanadium-titanium magnetite structures, specifically: a high ratio of the whole pellet magnesia vanadium and titanium + vanadium-titanium sinter high basicity + a small amount of alumina ore. The present invention refers to the ratio mentioned ultra high-basicity sinter vanadium and titanium, the proportion of all-vanadium-titanium magnetite from 80% to 100%. The present invention is referred to a high basicity sinter it refers to vanadium-titanium sinter basicity CaO / SiO 2 Greater than 2.0.

[0034] Table 1: Comparison Table of the prior art

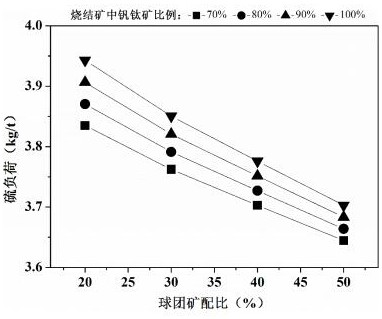

[0035] Example Pocolite Sinter Block mine Vanadium-titanium mine accounts for a percentage of total furnace Sulfur load kg / t current technology 20% 75% 0-5% 50.05~53.90 3.805~3.835 this invention 40%~50% 47%~55% 2%~5% 84~88 3.703~3.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com