Alkali metal composite negative electrode material and preparation method thereof

A negative electrode material, alkali metal technology, applied in the field of alkali metal composite negative electrode materials and its preparation, can solve the problems of poor control of negative electrode surface reaction uniformity, unstable SEI film on the surface, and fluctuations in Coulombic efficiency. Large-scale industrial production, good alkali metal deposition effect, and the effect of inhibiting volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

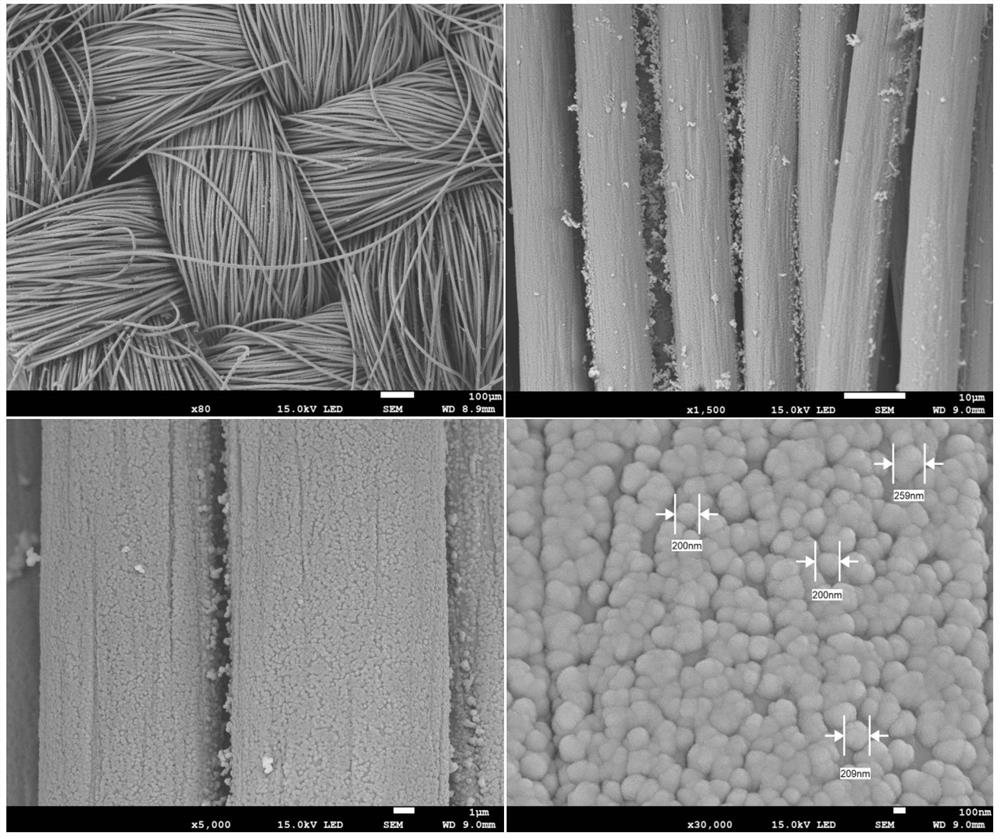

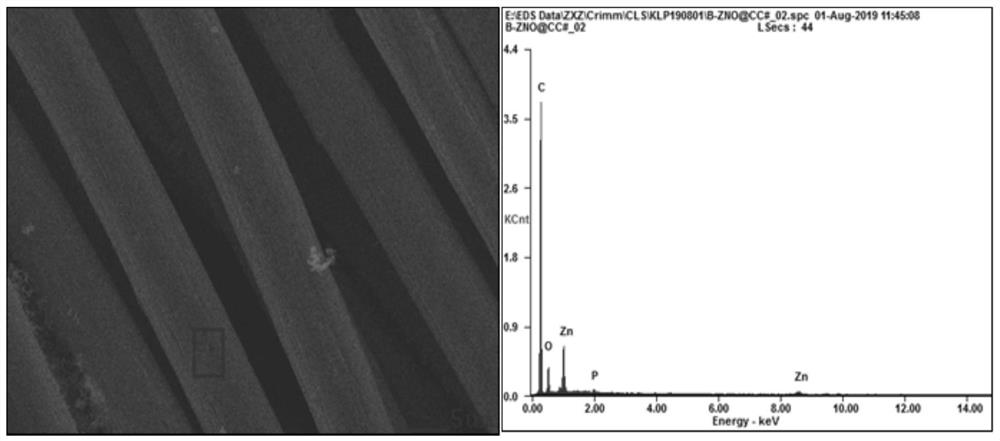

[0048] The alkali metal composite negative electrode material in this embodiment includes carbon cloth, zinc oxide coated on the surface of the carbon cloth, and metal lithium supported on the carbon cloth, wherein the coating thickness of the zinc oxide is 200 nm.

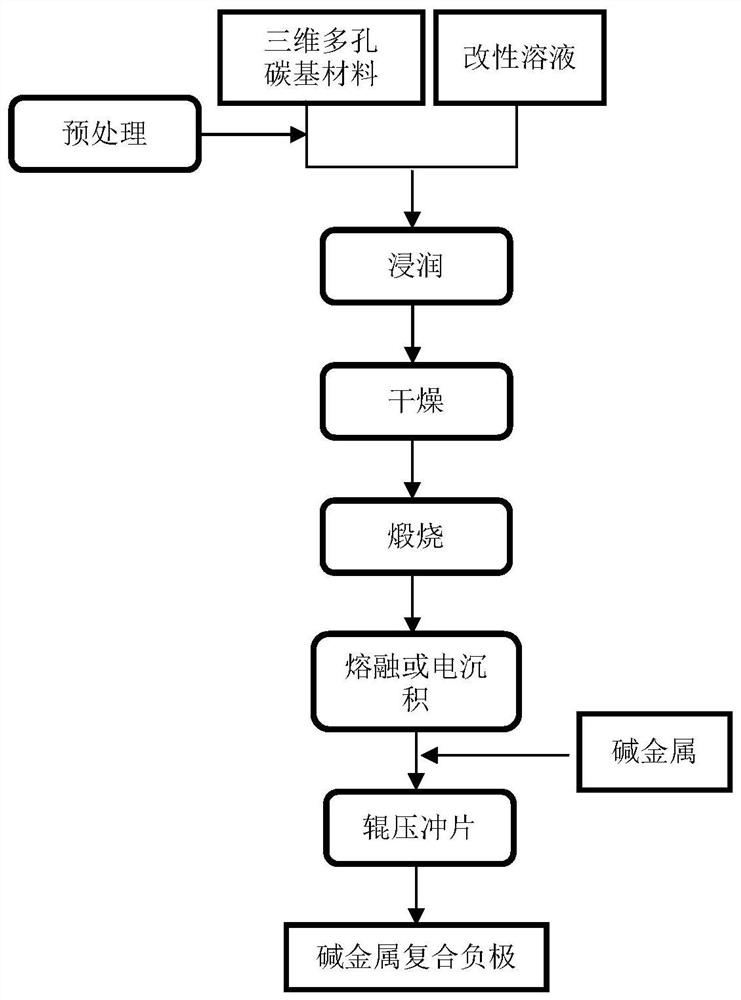

[0049] Such as figure 1 As shown, the preparation method of the alkali metal composite negative electrode material in this embodiment has a simple process and is suitable for large-scale industrial production, and specifically includes the following steps:

[0050] (1) Pretreatment: After the carbon cloth is cut into pieces, it is ultrasonically cleaned for 120 minutes under the conditions of acetone, ethanol and ultrapure water, and then dried to remove water; the dried carbon cloth is placed in 98wt% concentrated sulfuric acid solution at 80 °C After soaking for 6 hours, put it into 68wt% concentrated nitric acid solution and soak for 6 hours at 90°C. Finally, it was ultrasonically cleaned with ethanol and ultr...

Embodiment 2

[0065] The alkali metal composite negative electrode material in this embodiment includes carbon cloth, copper oxide coated on the surface of the carbon cloth, and metal sodium supported on the carbon cloth, wherein the coating thickness of the copper oxide is 300 nm.

[0066] Figure 5 The physical picture of the alkali metal composite negative electrode material (Na / ZnO@CC) prepared for this example, it can be seen from the picture that the metallic sodium with silvery white metallic luster is evenly adsorbed on the carbon cloth.

[0067] The preparation method of the alkali metal composite negative electrode material of the present embodiment comprises the following steps:

[0068] (1) Pretreatment: After the carbon cloth is cut into pieces, it is ultrasonically cleaned for 120 minutes under the conditions of acetone, ethanol and ultrapure water, and then dried to remove water; the dried carbon cloth is placed in 98wt% concentrated sulfuric acid solution at 80 °C After soa...

Embodiment 3

[0076] The alkali metal composite negative electrode material in this embodiment includes carbon cloth, a nitrogen and phosphorus coating layer coated on the surface of the carbon cloth, and metal potassium supported on the carbon cloth, wherein the coating thickness is 500 nm.

[0077] The preparation method of the alkali metal composite negative electrode material of the present embodiment comprises the following steps:

[0078] (1) Pretreatment: After the carbon cloth is cut into pieces, it is ultrasonically cleaned for 120 minutes under the conditions of acetone, ethanol and ultrapure water, and then dried to remove water; the dried carbon cloth is placed in 98wt% concentrated sulfuric acid solution at 80 °C After soaking for 6 hours, put it into 68wt% concentrated nitric acid solution and soak for 6 hours at 90°C. Finally, it was ultrasonically cleaned with ethanol and ultrapure water and dried for later use.

[0079] (2) Modification solution preparation: 3.512 g of amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com