Polyimide film and flexible display device cover substrate by using same

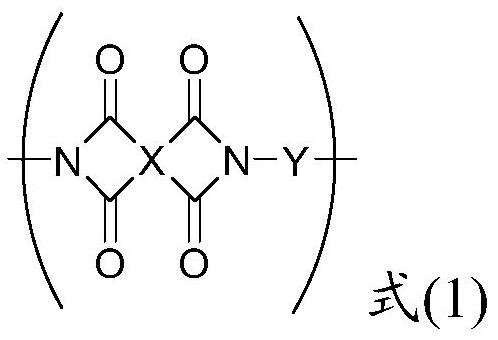

A technology of polyimide film and flexible display device, which is applied in the field of covering substrate of flexible display device, can solve the problem that infrared heating process cannot be used, and achieve the effects of improving yellowish phenomenon, increasing production rate and shortening baking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

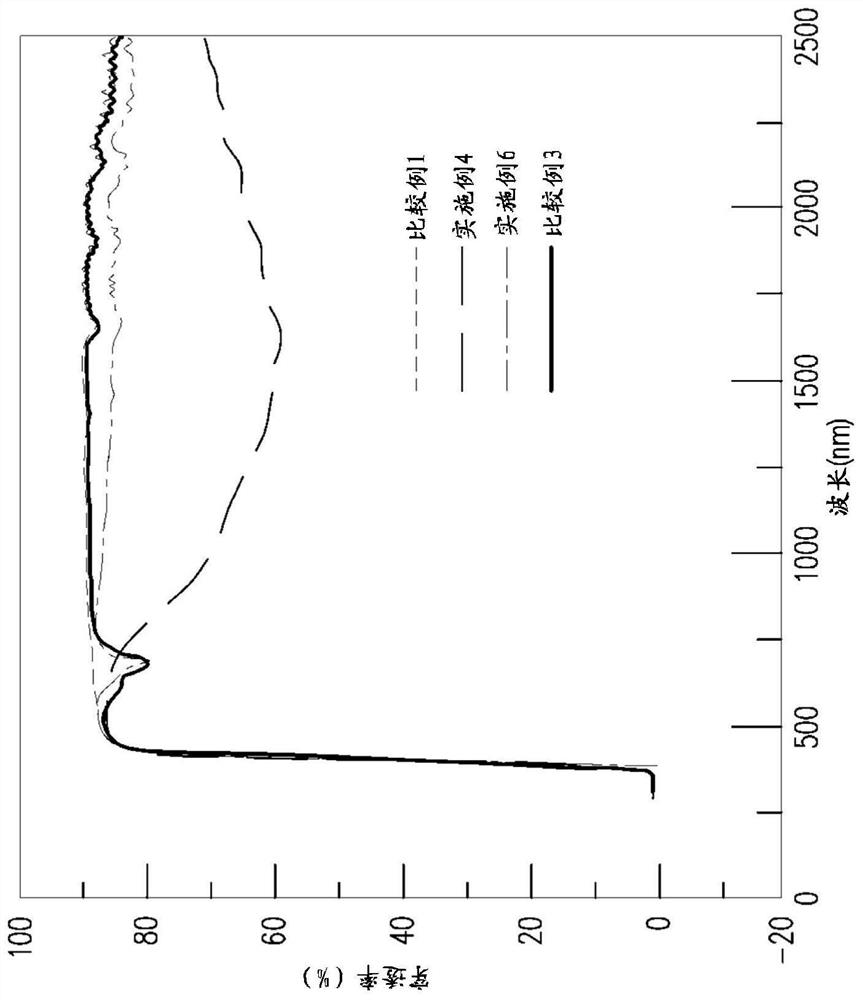

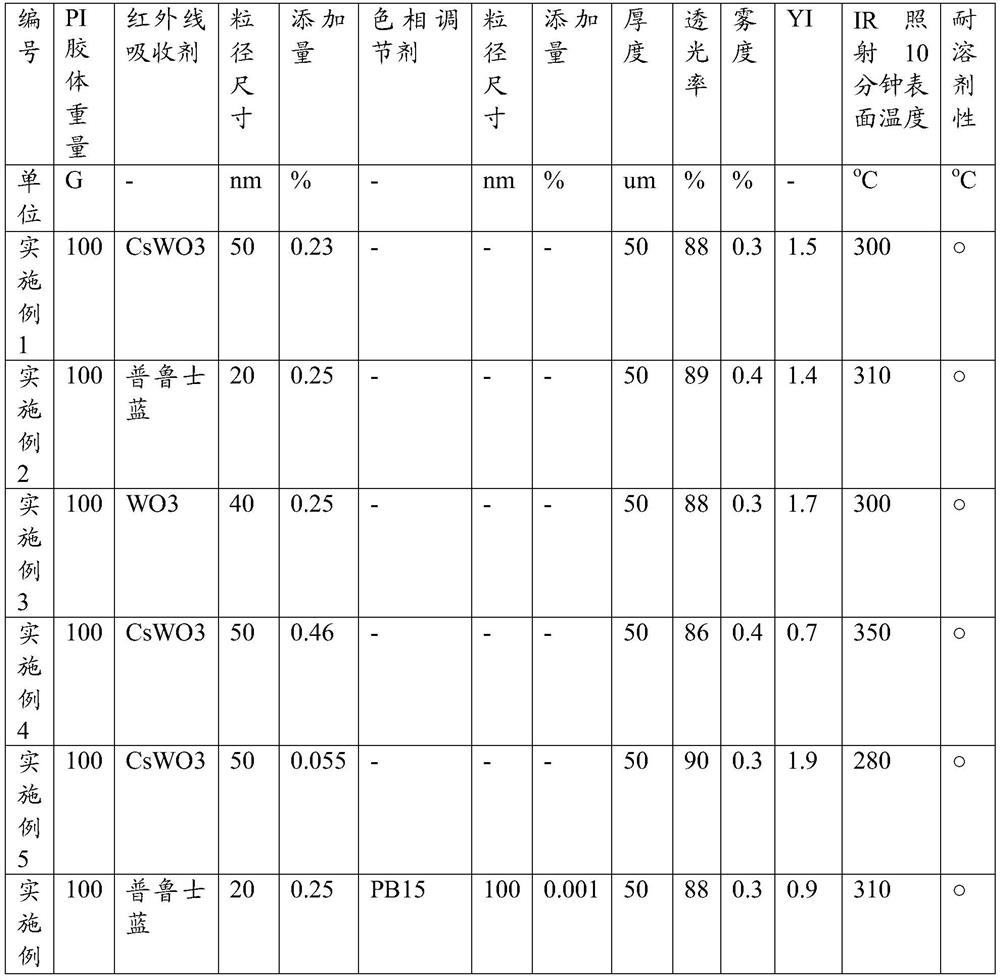

[0059] In order to prove that the polyimide film of the present invention has good performance, the following experiment example is specially made.

[0060] Prepare polyimide solution

Synthetic example 1

[0062] 8.97g (0.028mole) of 2,2'-bis(trifluoromethyl)benzidine (TFMB), 2.40g (0.012mole) of 4,4'-diaminodiphenyl ether (ODA) and 100g of Dimethylacetamide (DMAc) was placed in a three-necked flask. After stirring at 30°C until completely dissolved, add 8.8g (0.02mole) of 2,2'-bis-(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (6FDA) and 5.88g (0.02mole) The biphenyltetracarboxylic dianhydride (BPDA) was continuously stirred and reacted at 25° C. for 24 hours to obtain a polyamic acid solution. Thereafter, 7.46 g (0.06 mole) of pyridine and 12.252 g (0.12 mole) of acetic anhydride were added, followed by continuous stirring and reaction at room temperature for 24 hours. After the reaction, polyimide was precipitated with methanol / water (volume ratio 1:2), and the powder was collected by filtration and dried to obtain polyimide powder. Finally, the powder was dissolved in dimethylacetamide solvent to form a 20 wt% polyimide solution.

[0063] Preparation of polyimide film...

Embodiment 1

[0065] Get 100 grams of polyimide solution of synthesis example 1 and add 0.86 gram of cesium tungsten oxide CsWO 3 (particle size 50nm, dispersed in dimethylacetamide, concentration 5wt%), after stirring and mixing for 30 minutes, apply a doctor blade on a glass substrate and place it in an oven for surface drying. The surface drying temperature is 100°C. Then, the polyimide film is obtained by heating and baking at an infrared wavelength of 800 nm to 3000 nm for 10 minutes under a nitrogen atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com