Insulation board production line

A production line and insulation board technology, applied in textiles and papermaking, static electricity, electrical components, etc., can solve problems such as long curing time, difficult pressurization, and small thickness of insulation boards, so as to improve material uniformity, improve automation capabilities, Effect of reducing fiber static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

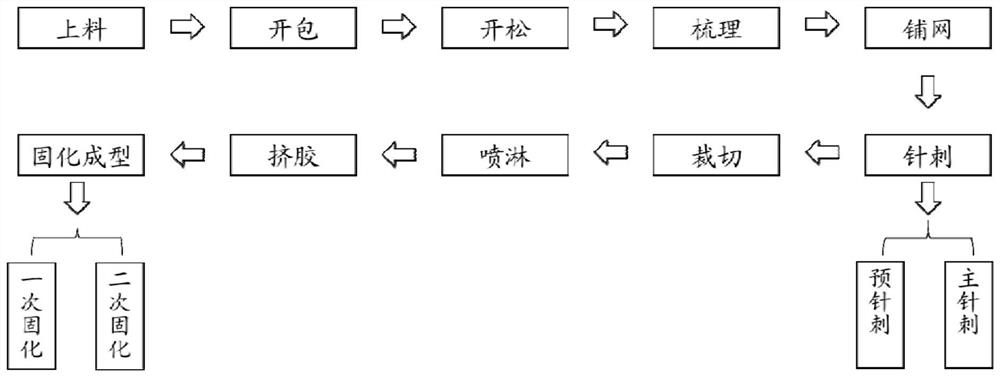

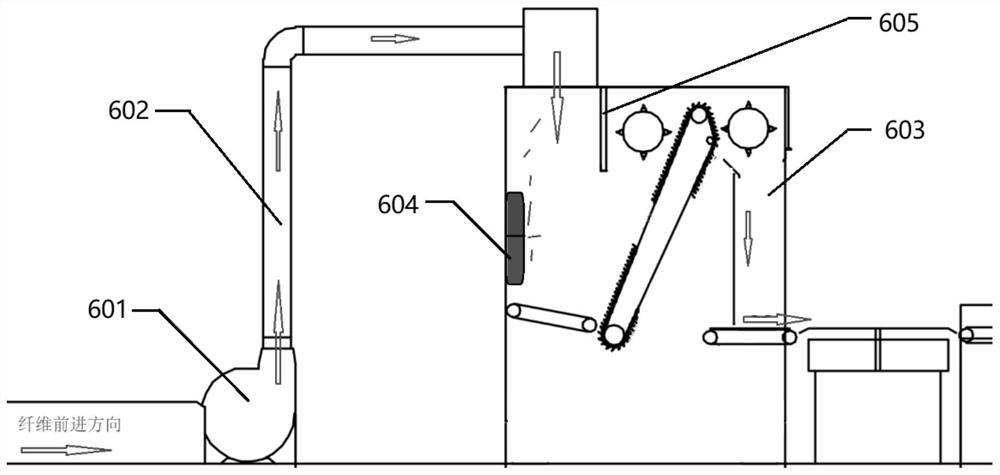

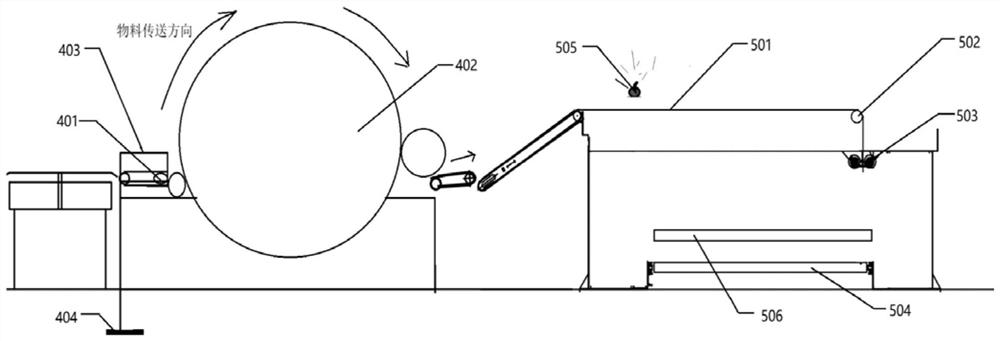

[0092] A production line for thermal insulation boards for building exterior walls, comprising the steps of feeding, unpacking, opening, carding, net laying, acupuncture, cutting, spraying, extruding glue, and curing molding. The raw materials of the insulation board are: glass fiber and water-soluble phenolic resin, among which, the glass fiber preparation: 4860kg of non-alkali glass fiber, 14580kg of medium-alkali glass fiber, the wire diameter is 10μm, and the length is 75mm. The water-soluble phenolic resin stock is 3240kg, the viscosity at 25°C is 13cp, the solid content is 49wt%, and the pH is 10.0.

[0093] The glass fiber passes through the automatic feeding machine (122kg non-alkali glass fiber and 365kg medium-alkali glass fiber per hour), bag unpacking machine, opening machine, carding machine, web laying machine, needle punching machine, conveyor to the spraying machine ( Spray water-soluble resin 99kg / h), microwave curing equipment for primary curing, and microwav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com